Water-retaining building adhesive and preparation process thereof

An adhesive and water-retaining technology, applied in the direction of adhesives, adhesive additives, epoxy resin glue, etc., can solve the problems of construction adhesives such as general water retention, poor fluidity, and affecting operation, and achieve the effect of improving water resistance , avoid the use of organic solvents, improve the effect of water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: polyvinyl butyral, it is prepared by the following method:

[0026] Mix PVA-1788 polyvinyl alcohol and water at a mass ratio of 1:15, raise the temperature to 80°C, add hydrochloric acid to adjust the pH to 2.5, add butyraldehyde and stir at a constant temperature for 90 minutes, the obtained glue appears white, which is the end of the reaction; Adjust the pH to 7.3 with an aqueous sodium hydroxide solution, cool to room temperature, and remove the solvent to obtain polyvinyl butyral with an acetalization degree of 68-72%.

Embodiment 2

[0027] Embodiment 2: ammonium zirconium carbonate, which is prepared by the following method: take zirconium oxychloride and water and mix them at a mass ratio of 1:10, adjust the temperature to 25° C. and stir to dissolve, add ammonium bicarbonate under heat preservation conditions, and stir for 30 minutes. The solvent was removed by lyophilization to obtain ammonium zirconium carbonate; the molar ratio of zirconium oxychloride to ammonium bicarbonate was 2.1:1.

Embodiment 3

[0028] Embodiment 3: A water-retaining construction adhesive, which is prepared by the following method: polyvinyl butyral (prepared in Example 1), polyvinyl alcohol (PVA-1788 type), bisphenol A type Epoxy resin (Jusheng brand E03 type), PEO-PPO-PEO triblock copolymer (P123 type), methyl cellulose and water are mixed, stirred and heated to 90°C to dissolve completely; after holding for 30min, cool down to 55°C ℃, add the formulated amount of ammonium persulfate, stir and react for 30 minutes; add the formulated amount of dibutyl phthalate, kaolin (4000 mesh, for coating), ammonium zirconium carbonate, corn starch (just meet GB / T8885-2017 , select COFCO brand) and potassium carbonate this time, stir evenly, obtain product.

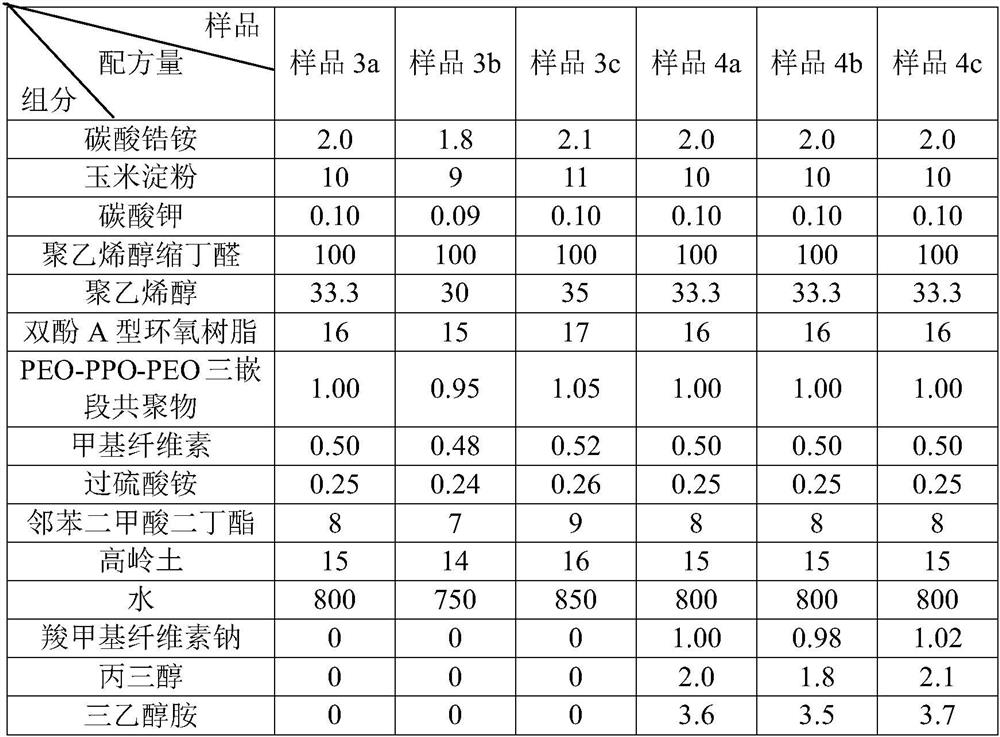

[0029] The formulation information of a water-retaining construction adhesive (sample 3a, sample 3b and sample 3c) of this embodiment is shown in Table 1, and the unit in Table 1 is parts by weight.

[0030] Table 1

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com