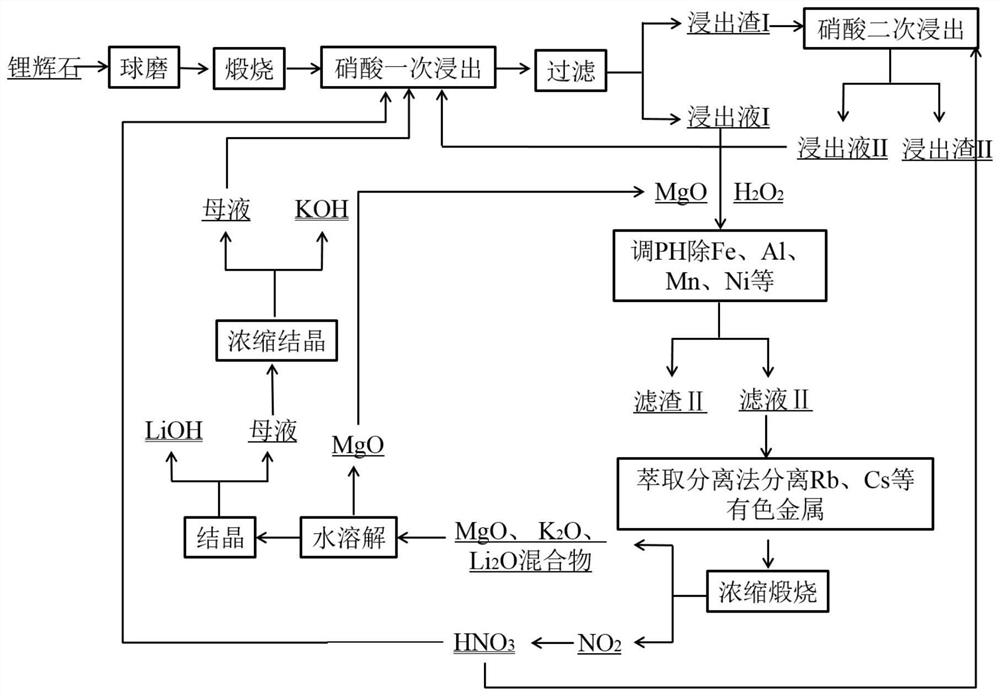

Method for extracting lithium through secondary reverse leaching of spodumene by nitric acid

A spodumene and leaching technology, which is applied in the field of secondary reverse leaching of spodumene with nitric acid to extract lithium, can solve the problems of large slag production, inability to guarantee the extraction of lithium and other metal elements, etc., to reduce the amount of nitric acid and facilitate the realization of industrial The effect of chemicalization and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

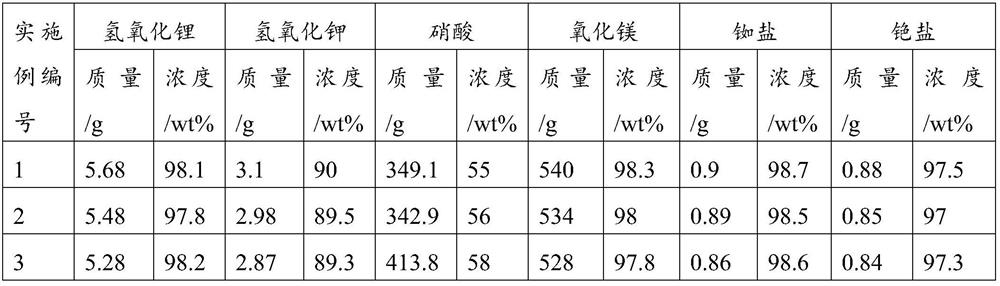

Embodiment 1

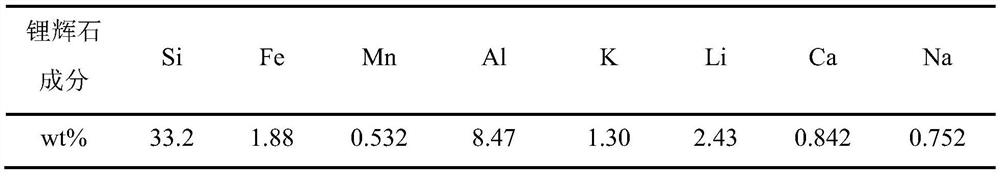

[0031] Adopt the method of the present invention to carry out lithium extraction to the spodumene raw material in table 1, specifically comprise the following steps:

[0032] S1: The spodumene raw material is ball milled so that the average particle size of the calcined material is less than 48 μm, and the spodumene is calcined at 1000° C. for 2.5 hours after ball milling;

[0033] S2: After calcination, spodumene and water are beaten according to the liquid-solid mass ratio of 2.5:1, and then nitric acid is added into the slurry according to 60wt% of the theoretical amount required for the main elements participating in the reaction, and the obtained solid-liquid mixture is carried out at a water bath temperature of 90°C One nitric acid leaching reaction, the reaction time is 3h, the solid-liquid mixture obtained after the reaction is filtered to obtain the leachate I and the leach residue I;

[0034] S3: The leaching slag I prepared in step S2 is beaten with water according ...

Embodiment 2

[0041] Adopt the method for embodiment 1 to carry out lithium extraction to the spodumene raw material in table 1, difference is:

[0042] In S1, the calcination temperature of spodumene is 980°C, and the calcination time is 1.5h;

[0043] In S2, the amount of nitric acid is 70wt% of the theoretical amount required for the main elements participating in the reaction, the liquid-solid mass ratio is 4:1, the water bath temperature is 100°C, and the leaching time is 2.5h;

[0044] In S3, the amount of nitric acid is 125wt% of the theoretical amount required for the main elements participating in the reaction, the liquid-solid mass ratio is 4:1, the acid leaching temperature is 160°C, and the leaching time is 2.5h;

[0045] In S4, MgO was added to adjust the pH of the solution to 9 and stirred for 1.5 h, and the reaction temperature was 65° C.;

[0046] In S5, the filtrate I obtained in step S4 is separated by extracting agent (t-BAMBP), diluent sulfonated kerosene, and sulfuric ...

Embodiment 3

[0049] Adopt the method for embodiment 1 to carry out lithium extraction to the spodumene raw material in table 1, difference is:

[0050] In S1, the calcination temperature of spodumene is 950°C, and the calcination time is 2h;

[0051] In S2, the amount of nitric acid is 50wt% of the theoretical amount required for the main elements participating in the reaction, the liquid-solid mass ratio is 2:1, the water bath temperature is 85°C, and the leaching time is 2h;

[0052] In S3, the amount of nitric acid is 130wt% of the theoretical amount required for the main elements participating in the reaction, the liquid-solid mass ratio is 2:1, the acid leaching temperature is 145°C, and the leaching time is 2h;

[0053] In S4, MgO was added to adjust the pH of the solution to 7 and stirred for 2 hours, and the reaction temperature was 70°C;

[0054] In S6, the filtrate I obtained in step S5 after extracting non-ferrous metals such as rubidium and cesium is concentrated and calcined,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com