Graphene quantum dot composite plating solution, preparation method and electroplating process

A technology of graphene quantum dots and composite plating solution, applied in electrolytic coatings, coatings, etc., can solve problems such as unstable mechanical properties of nickel-based materials, increase nucleation rate, reduce open circuit potential value, and improve corrosion resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

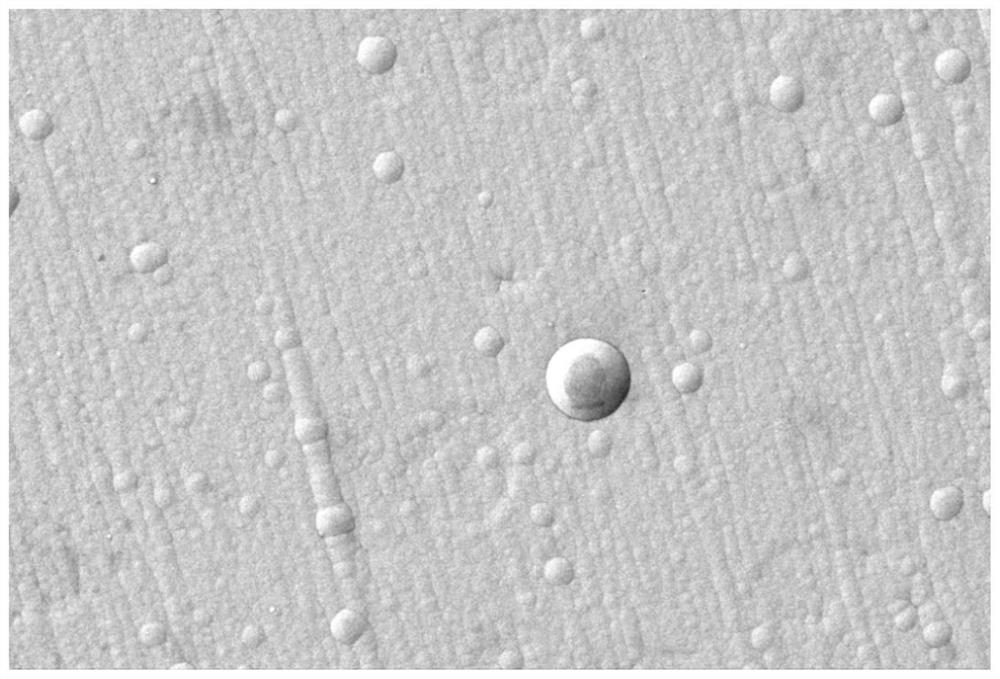

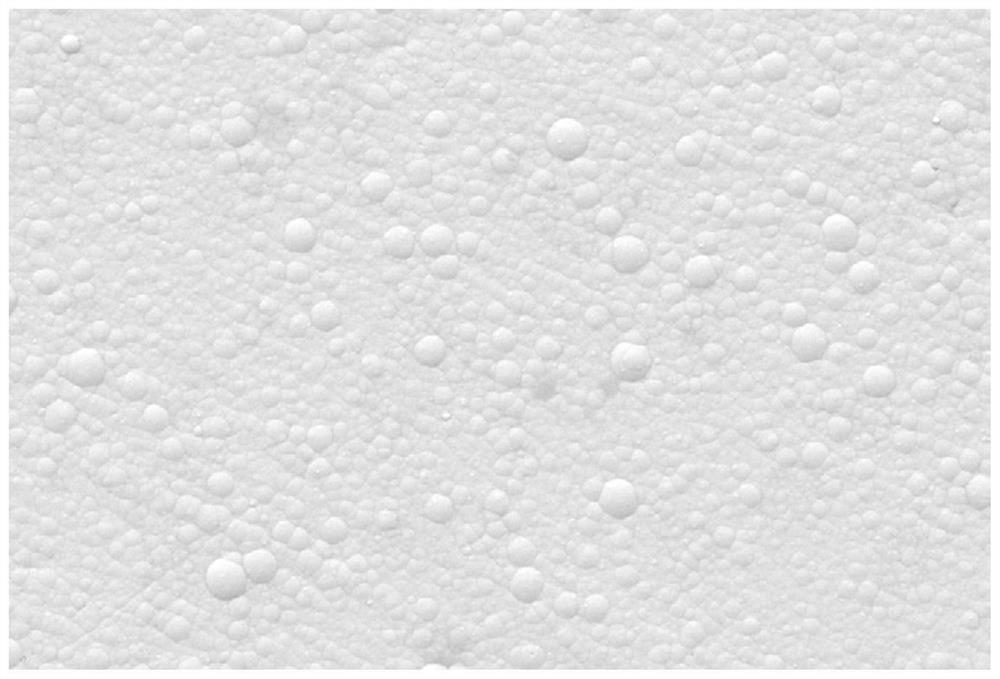

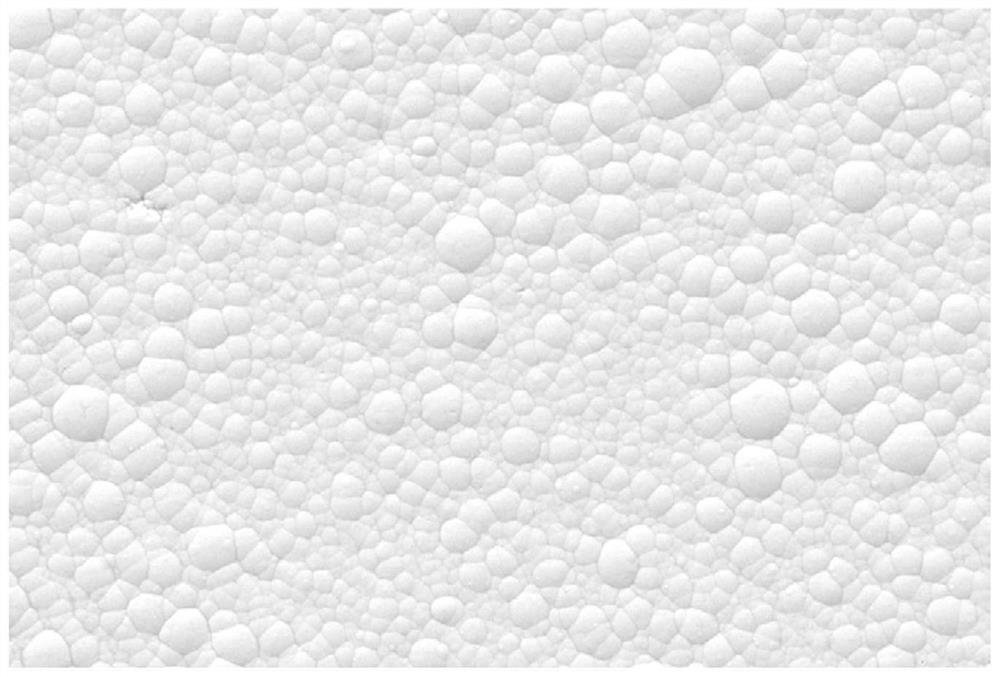

Image

Examples

Embodiment 1

[0041] 1) Add graphene quantum dots to deionized water with a total preparation volume of 1 / 2, and magnetically stir for 50 minutes under dark and ultrasonic conditions to obtain a solution;

[0042] 2) Add nickel sulfate, nickel chloride, boric acid and organic additives (sodium lauryl sulfate) to deionized water of 1 / 2 of the total preparation amount, and magnetically stir for 20 minutes under ultrasonic conditions to obtain a mixed solution;

[0043] 3) the graphene quantum dot solution prepared in step 1) is mixed with the mixed solution prepared in step 2), and magnetically stirred for 50 min under dark and ultrasonic conditions, and TMN surfactant is added during the stirring process to obtain graphene quantum dots Composite solution, the concentration of each component in the composite solution is as follows

[0044]

[0045] The speed of magnetic stirring in step 1)-3) is selected 300r / min;

[0046] 4) The pretreated (i.e. derusted with dilute hydrochloric acid, sa...

Embodiment 2

[0048] The difference between embodiment 2 and embodiment 1 is that the addition of graphene quantum dots in the graphene quantum dot composite solution is different, and in step 3) the concentration of graphene quantum dots in the graphene quantum dot composite solution prepared is: 1.5g / L. All the other steps are the same as in Example 1.

Embodiment 3

[0050] The difference between embodiment 3 and embodiment 1 is that the addition of graphene quantum dots in the graphene quantum dot composite solution is different, and in step 3) the concentration of graphene quantum dots in the graphene quantum dot composite solution prepared is: 2.0g / L. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com