Optical oxygen sensing diaphragm as well as preparation method and application thereof

An oxygen sensing film and optical technology, which is applied in the field of oxygen sensing and detection, can solve the problems of inability to detect the change of oxygen concentration in solution and air at the same time, high cost, complicated process of oxygen sensing film, etc., so as to improve the detection accuracy and cost. Low, good response reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A second aspect of the present invention provides a method for preparing an optical oxygen sensing diaphragm, comprising the following steps:

[0043] Step 1. Import the 3D model file of the chip layer into the relevant software of the 3D printer, perform 3D printing to obtain the printed structure, and then perform ultraviolet curing on the printed structure to obtain the chip layer;

[0044] Step 2, preparing a fluorescent oxygen sensing film layer;

[0045]Step 3: Evenly smear a UV-curable adhesive on the upper surface of the chip layer, bond the fluorescent oxygen sensing film layer to the upper surface of the chip layer correspondingly, and cure under ultraviolet light to obtain an optical oxygen sensing membrane.

[0046] In some embodiments of the present invention, the software used by the 3D printer in step 1 is Preform.

[0047] In some embodiments of the present invention, in step 1, the support structure of the chip layer, layer thickness, printing material...

Embodiment 1

[0069] Embodiment 1: Preparation of Optical Oxygen Sensing Diaphragm

[0070] (1) Preparation of chip layer

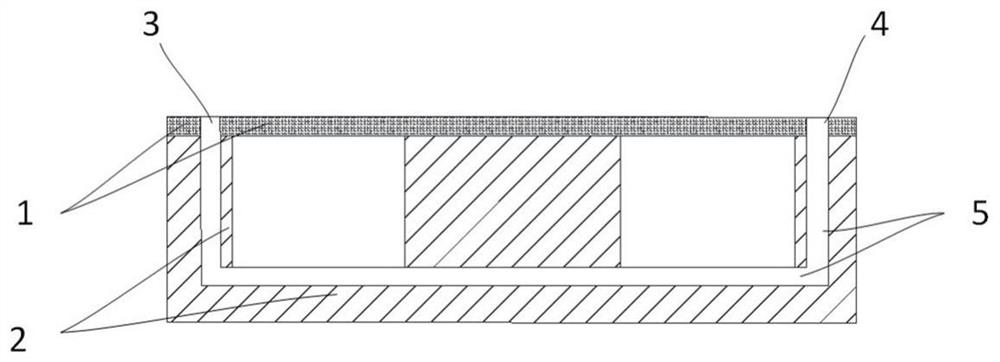

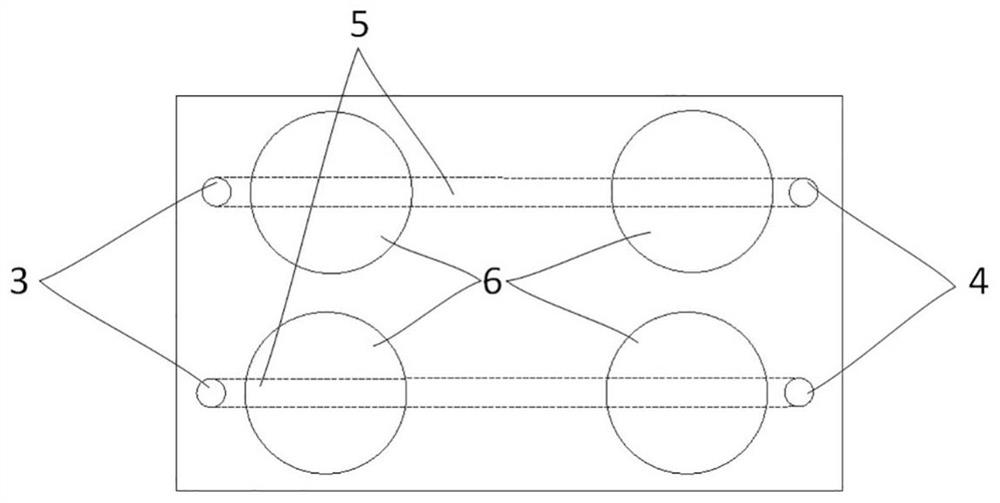

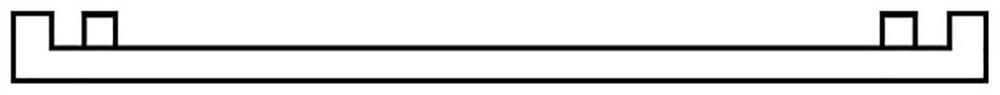

[0071] Import the 3D model file into the relevant software of the 3D printer—Preform, set the parameters such as the support structure, layer thickness and material required for 3D printing, and then connect to the 3D printer for printing; among them, the support structure is as follows: figure 1 As shown, it includes dual channels set in parallel, 4 detection areas, 2 inlets, and 2 outlets.

[0072] After printing, soak the printed structure in isopropanol solution for 3 hours to wash off excess uncured printing material; then put it into a UV post-curing box for post-curing. The temperature of the curing box is set at 35°C and the curing time is 3 hours. ~5h.

[0073] (2) Preparation of fluorescent oxygen sensing film layer

[0074] S1. Configure the fluorescent indicator solution, and dissolve the fluorescent indicator tris(4,7-biphenyl-1,10-phenanthroline) ruthe...

Embodiment 2

[0081] Embodiment 2: The usage method of optical oxygen sensing diaphragm

[0082] The performance test of the optical oxygen sensing diaphragm is carried out by using a fluorescence spectrometer. The two channels are respectively passed into the sample (gas or liquid) saturated with nitrogen and oxygen, and the flow rate of the two peristaltic pumps is mixed and adjusted through the three-way valve. Adjust the concentration of nitrogen and oxygen, connect through the pipeline, and finally enter the entrance of the optical oxygen sensing diaphragm, place the optical oxygen sensing diaphragm in the detection sample cell of the fluorescence spectrometer, adjust the parameters of the spectrometer, the excitation wavelength is 460nm, the slit width is 10nm, Collect the wavelength range of 480-800nm, detect the fluorescence intensity, and determine the oxygen concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com