Film composite material based on nanocellulose-graphene oxide as well as preparation method and application of film composite material

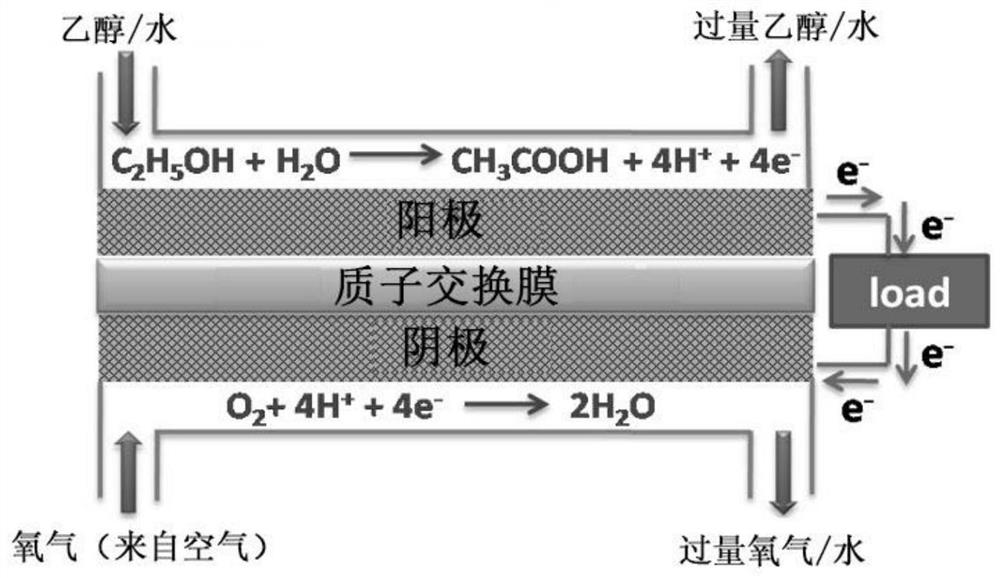

A thin-film composite material and nano-cellulose technology, which is applied in the analysis of materials, material analysis through electromagnetic means, instruments, etc., can solve the problem that the cellulose film cannot block the passage of gas, achieve excellent detection performance, simple process flow, and raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

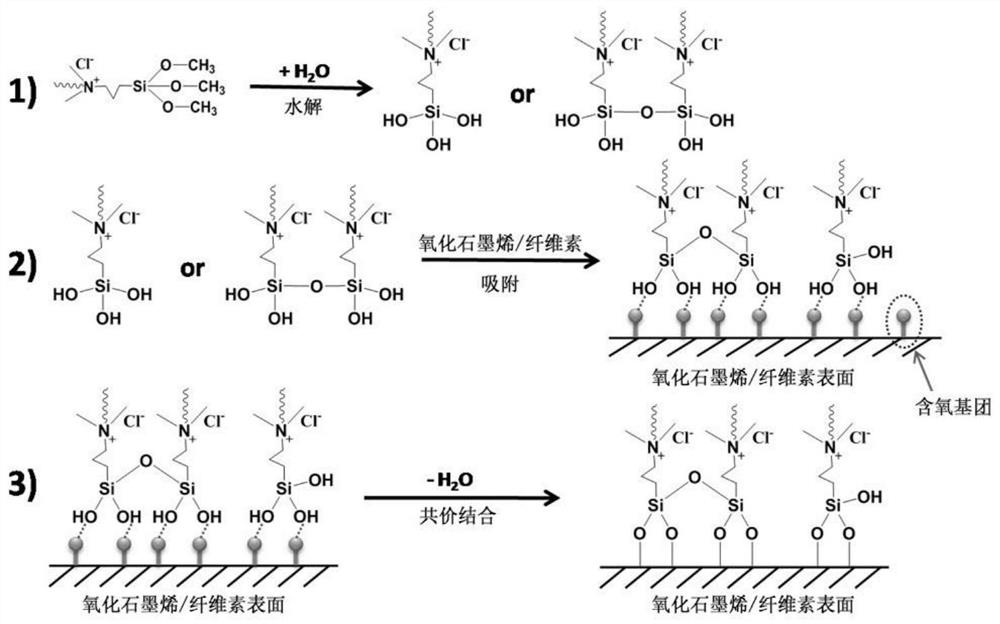

Method used

Image

Examples

Embodiment 1

[0047] (1) Preparation of graphene oxide and nanocellulose

[0048] The preparation of graphene oxide was prepared by Hummers' method: first, 360mL of 98% concentrated sulfuric acid and 40mL of 85% concentrated phosphoric acid were mixed in a round bottom flask under ice bath conditions, and then 2g of graphite powder was slowly added to the mixed concentrated acid, mechanically Stir for 1h. Slowly add 18g of strong oxidant potassium permanganate into the mixture, keep stirring at 50°C for 16h, then cool the solution to stop the oxidation reaction. Add 400 mL of deionized water and 20 mL of hydrogen peroxide solution dropwise into the mixed solution, and stir for 30 min. Subsequently, the mixed solution was centrifuged and washed with deionized water, 5% hydrochloric acid solution and ethanol solution, respectively. Finally, the graphene oxide solution is freeze-dried to obtain graphene oxide powder.

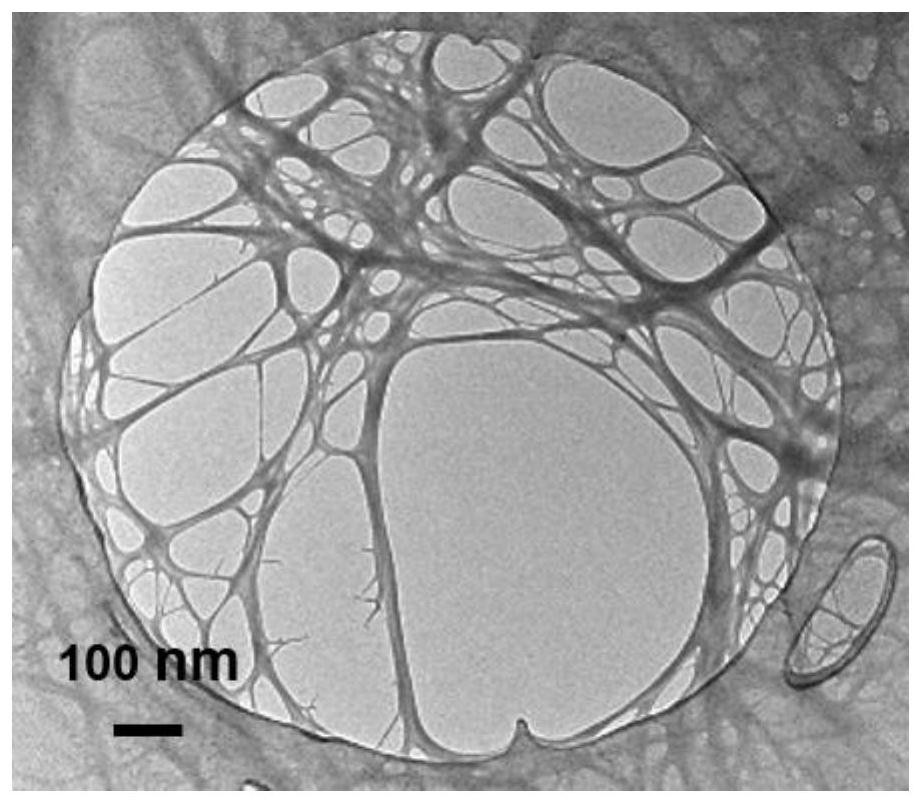

[0049] The raw material for the preparation of cellulose nanofibers is p...

Embodiment 2

[0054] (1) Preparation of graphene oxide and nanocellulose

[0055] The preparation of graphene oxide was prepared by Hummers' method: first, 360mL of 98% concentrated sulfuric acid and 40mL of 85% concentrated phosphoric acid were mixed in a round bottom flask under ice bath conditions, and then 2g of graphite powder was slowly added to the mixed concentrated acid, mechanically Stir for 1h. Slowly add 18g of strong oxidant potassium permanganate into the mixture, keep stirring at 50°C for 16h, then cool the solution to stop the oxidation reaction. Add 400 mL of deionized water and 20 mL of hydrogen peroxide solution dropwise into the mixed solution, and stir for 30 min. Subsequently, the mixed solution was centrifuged and washed with deionized water, 5% hydrochloric acid solution and ethanol solution, respectively. Finally, the graphene oxide solution is freeze-dried to obtain graphene oxide powder.

[0056] The raw material for the preparation of cellulose nanofibers is p...

Embodiment 3

[0061] (1) Preparation of graphene oxide and nanocellulose

[0062] The preparation of graphene oxide was prepared by Hummers' method: first, 360mL of 98% concentrated sulfuric acid and 40mL of 85% concentrated phosphoric acid were mixed in a round bottom flask under ice bath conditions, and then 2g of graphite powder was slowly added to the mixed concentrated acid, mechanically Stir for 1h. Slowly add 18g of strong oxidant potassium permanganate into the mixture, keep stirring at 50°C for 16h, then cool the solution to stop the oxidation reaction. Add 400 mL of deionized water and 20 mL of hydrogen peroxide solution dropwise into the mixed solution, and stir for 30 min. Subsequently, the mixed solution was centrifuged and washed with deionized water, 5% hydrochloric acid solution and ethanol solution, respectively. Finally, the graphene oxide solution is freeze-dried to obtain graphene oxide powder.

[0063] The raw material for the preparation of cellulose nanofibers is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com