Efficient and recyclable pH test paper and preparation method thereof

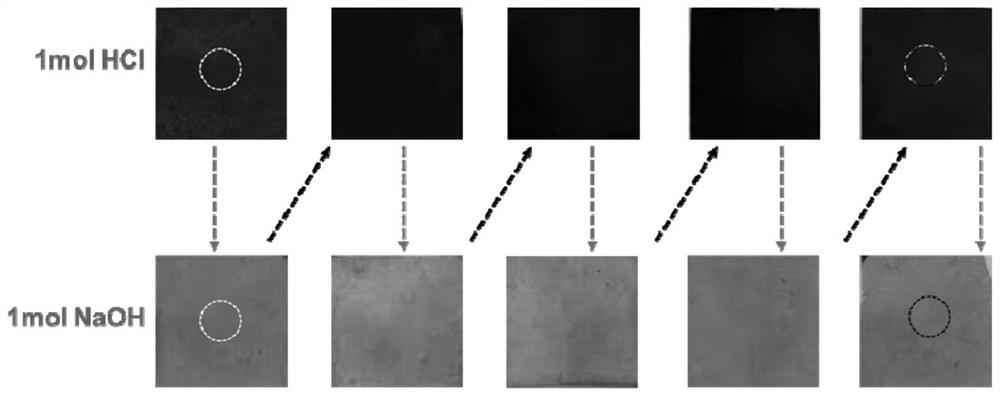

A ph test paper, an efficient technology, is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions. It can solve problems such as inability to combine ions, inability to carry, and white oil repulsion Achieve high-efficiency color rendering, easy to carry, and large degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

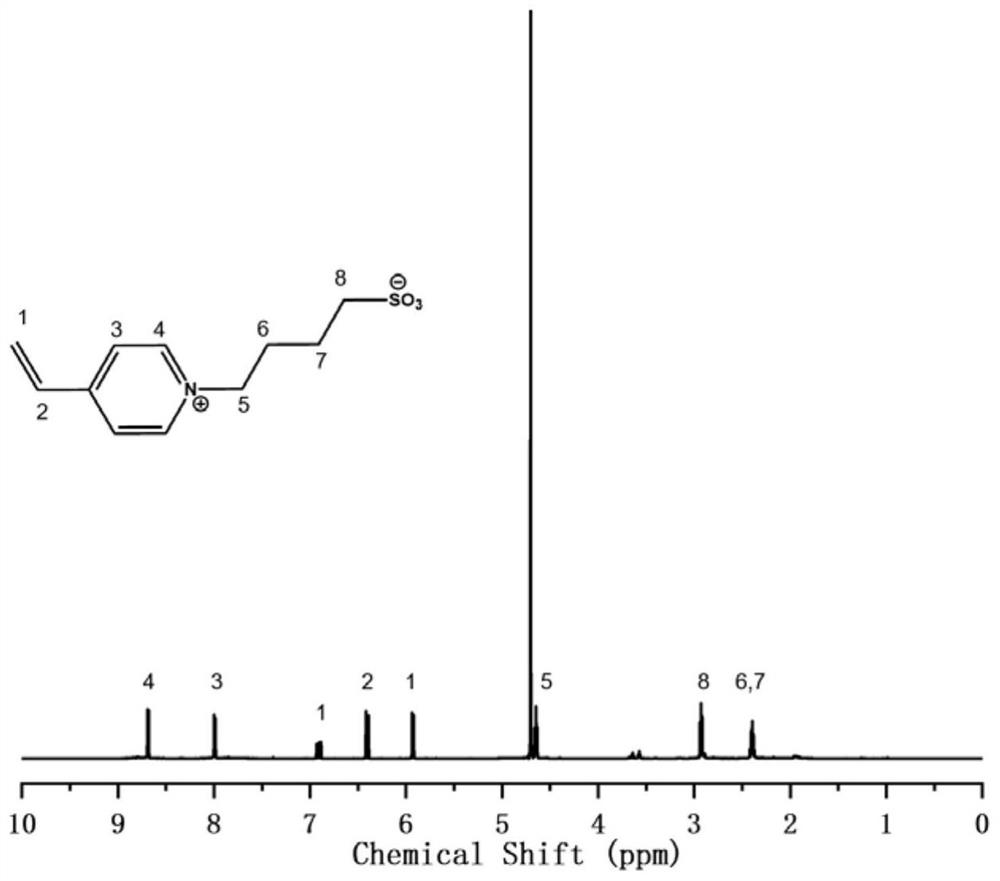

[0028] Add 4-vinylpyridine (10.51g, 0.1mol), butane sultone (17.70g, 0.13mol), and dry toluene into a 250ml three-neck flask in turn, stir until fully mixed, and blow nitrogen gas while stirring. The system was reacted for 24 hours at 100°C. After the reaction was completed, white crystals of 4-vinyl-1-(3-sulfobutyl)pyridine were precipitated in the solution. Next, the solution was subjected to suction filtration, while continuously washing with butanone for several times to collect white crystals.

[0029] Pour 4-vinyl-1-(3-sulfobutyl)pyridine (1.22 g, 0.005 mol) into dichloromethane to form a 1 mol / L solution. Next, add amylacrylamide (0.71g, 0.005mol), benzoin (0.0122g) and N,N-methylenebisacrylamide (0.15g) in sequence, mix well and drop the solution evenly on neutral glass fiber filter paper On, react under 365nm ultraviolet lamp for 40min. After drying to remove the solvent, pH test paper is prepared. The nuclear magnetic detection data of the chromogenic substances ...

Embodiment 2

[0031] Add 2,4-vinylpyridine (13.11g, 0.1mol), butane sultone (34.04g, 0.13mol), and dry toluene into a 250ml three-necked flask in turn, stir until fully mixed, and pass into nitrogen. The system was reacted for 30 hours at 115°C. After the reaction was completed, white crystals of 2,4-divinyl-1-(3-sulfobutyl)pyridine were precipitated in the solution. Next, the solution was subjected to suction filtration, while continuously washing with butanone for several times to collect white crystals.

[0032] Pour 2,4-divinyl-1-(3-sulfobutyl)pyridine (1.34 g, 0.005 mol) into dichloromethane to form a 1 mol / L solution. Next, add pentylacrylamide (0.71g, 0.005mol), benzoin butyl ether (0.0134g) and N,N-methylene bisacrylamide (0.15g) in sequence, mix well and drop the solution evenly on the neutral glass On fiber filter paper, react under 365nm ultraviolet light for 30min. After drying to remove the solvent, pH test paper is prepared.

Embodiment 3

[0034]Add 2-vinylpyridine (10.51g, 0.1mol), hexanesultone (21.35g, 0.13mol), and dry toluene into a 250ml three-neck flask in turn, stir until fully mixed, and blow nitrogen gas while stirring. The system was reacted for 20 hours at 75°C. After the reaction was completed, white crystals of 2-vinyl-1-(3-sulfohexyl)pyridine were precipitated in the solution. Next, the solution was subjected to suction filtration, while continuously washing with butanone for several times to collect white crystals.

[0035] Pour 2-vinyl-1-(3-sulfohexyl)pyridine (1.35 g, 0.005 mol) into chloroform to form a 5 mol / L solution. Next, sequentially add lauryl acrylamide (0.71g, 0.005mol), benzoin dimethyl ether (0.0135g) and N,N-methylenebisacrylamide (0.15g), mix well and drop the solution evenly on On cotton non-woven fabric, react under 365nm ultraviolet lamp for 40min. After drying to remove the solvent, pH test paper is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com