Nanoporous structure SiO2 coated ternary positive electrode material and preparation method and application thereof

A positive electrode material, nanoporous technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of electrochemical performance attenuation, battery capacity, cycle performance attenuation, phase transition, etc., and achieve uniform particle size distribution and good cycle Effect of performance and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

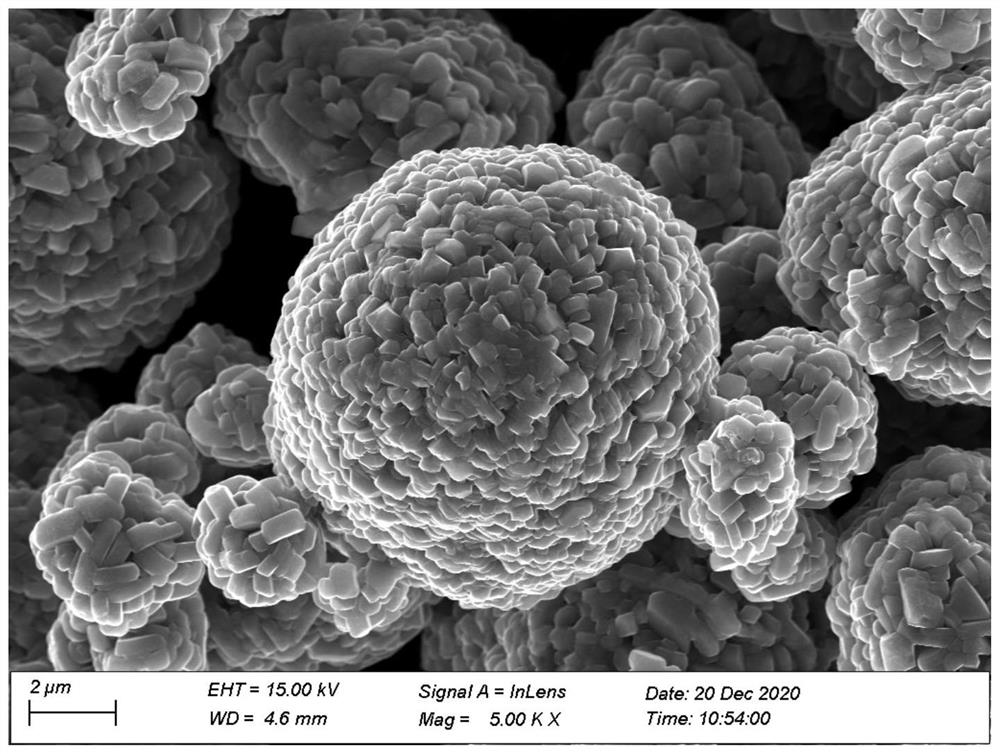

[0031] A nanoporous SiO 2 The preparation method of the coated ternary cathode material comprises the following steps:

[0032] (1) Preparation of ternary cathode material matrix: the precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 Mixed with lithium carbonate, then sintered in air at 910°C for 10 hours, followed by crushing and classification to obtain a ternary positive electrode material matrix with a weight of 1kg; wherein the molar ratio of lithium carbonate to precursor was 1.05;

[0033] (2) Add 5.00g of tetraethyl orthosilicate to 5.59g of ethanol solution, stir evenly, then add 0.17g of dilute hydrochloric acid and 100.00g of ethanol to the mixed solution of tetraethyl orthosilicate and ethanol under stirring condition The mixture was allowed to stand for 30 minutes to obtain a silicon coating solution;

[0034] (3) Add 1 kg of the ternary positive electrode material substrate prepared in step (1) to 250.00 g of ethanol solution, stir rapidly for 10 minutes, then add it to...

Embodiment 2

[0038] A nanoporous SiO 2 The preparation method of the coated ternary cathode material comprises the following steps:

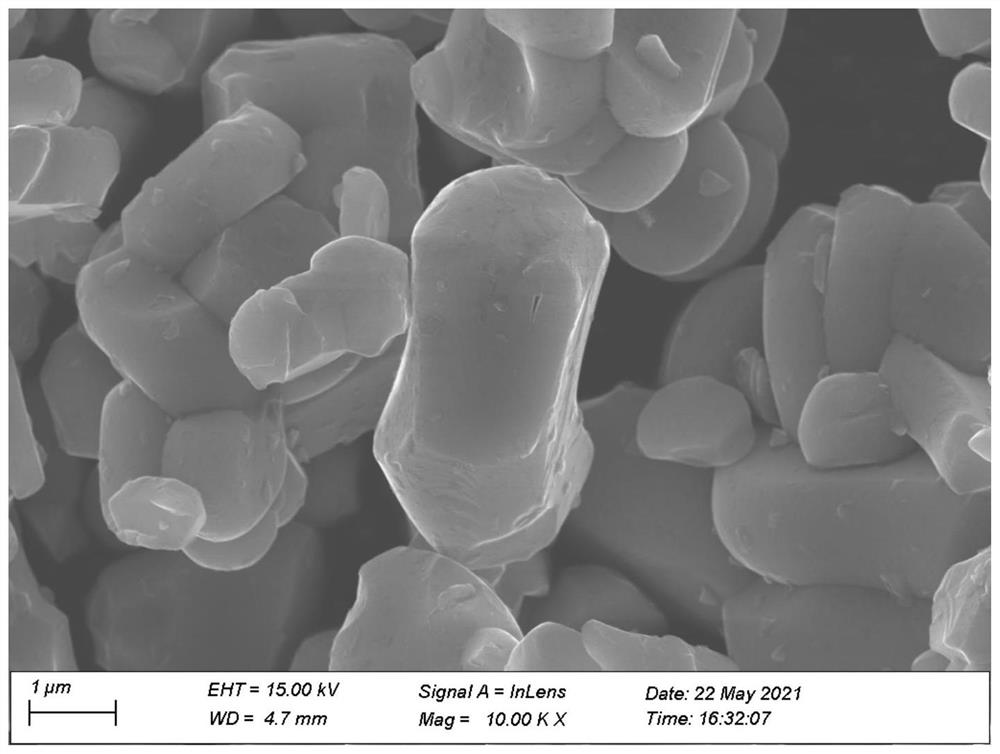

[0039] (1) Preparation of ternary cathode material matrix: the precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 Mixed with lithium carbonate, then sintered in air at 950°C for 12 hours, followed by crushing and classification to obtain a ternary positive electrode material matrix with a weight of 1kg; the molar ratio of lithium carbonate to precursor was 1.06;

[0040] (2) Add 10g of tetraethyl orthosilicate to 13.41g of ethanol solution, stir evenly, then add a mixture of 0.34g of dilute hydrochloric acid and 100.00g of ethanol to the mixed solution of tetraethyl orthosilicate and ethanol under stirring condition , standing for 30min to obtain the silicon coating solution;

[0041] (3) Add 1 kg of the ternary cathode material substrate prepared in step (1) to 333.33 g of ethanol solution, stir rapidly for 10 minutes, then add it to the silicon coating solution in...

Embodiment 3

[0045] A nanoporous SiO 2 The preparation method of the coated ternary cathode material comprises the following steps:

[0046] (1) Preparation of ternary cathode material matrix: the precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 Mixed with lithium carbonate, then sintered in the air at 865°C for 10 hours, and then crushed and classified to obtain a ternary positive electrode material matrix with a weight of 1kg; wherein the molar ratio of lithium carbonate to precursor was 1.05;

[0047] (2) Add 15.00g of tetraethyl orthosilicate to 23.46g of ethanol solution, stir well, then add 0.5g of dilute hydrochloric acid and 100.00g of ethanol to the mixed solution of tetraethyl orthosilicate and ethanol under stirring condition The mixture was allowed to stand for 30 minutes to obtain a silicon coating solution;

[0048] (3) Add 1 kg of the ternary positive electrode material substrate prepared in step (1) to 500.00 g of ethanol solution, stir rapidly for 10 minutes, then add it to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com