Method for preparing metal monatomic catalyst by hydrothermal method

A hydrothermal method and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as harsh reaction conditions and achieve rich active sites , avoid agglomeration, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 100 mg of nitrogen-doped carbon nanospheres to 50 mL of ultrapure water, stir to disperse to obtain a mixed solution A; add 90 mg of cobalt nitrate hexahydrate, and continue stirring for 30 minutes to obtain a mixed solution B, and 10 mL of 50 mg / mL thiourea The solution was added dropwise to the mixed solution B, and the dripping time was 3 minutes to obtain the mixed solution C; the mixed solution C was transferred to the polytetrafluoroethylene memory, packaged and transferred to the blast drying oven, and the reaction temperature was set at 180°C, and the reaction Time 8h; After the reaction is completed, cool to room temperature and collect the solid material; wash the solid material with ultrapure water, centrifuge 3-4 times, collect the solid material, put it in a blast drying oven at 80°C for 12 hours, and then obtain the carbon-supported metal single-atom catalysts.

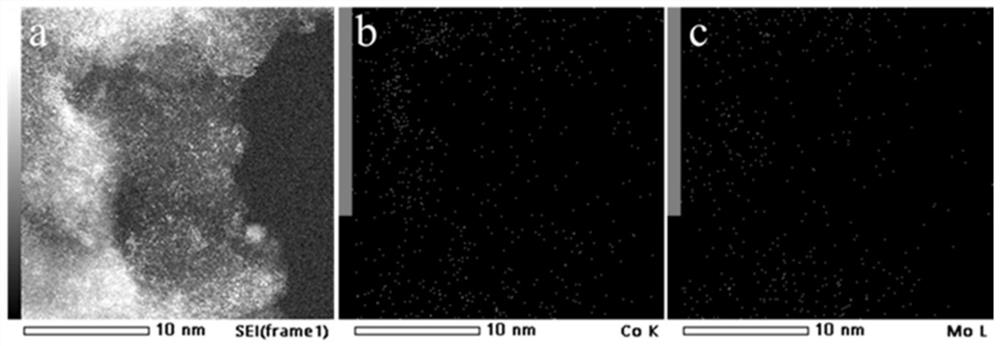

[0037] figure 1 a and 1b are spherical aberration-corrected high-angle annular dark-field...

Embodiment 2

[0042] Add 50mg of carbon nanospheres to 50mL of ultrapure water, stir to disperse to obtain mixed solution A; add 90mg of cobalt nitrate hexahydrate, continue stirring for 30min to obtain mixed solution B, add 10mL of 50mg / mL thiourea solution dropwise Into the mixed solution B, add dropwise for 3 minutes to obtain the mixed solution C; transfer the mixed solution C to a polytetrafluoroethylene memory, package it and transfer it to a blast drying oven, set the reaction temperature to 180°C, and the reaction time to 8 hours; After the reaction, cool to room temperature and collect the solid material; wash the solid material with ultrapure water, centrifuge 3-4 times, collect the solid material, put it in an 80°C blast drying oven for 12 hours, and obtain a carbon-supported metal single-atom catalyst .

Embodiment 3

[0044] Add 150mg of graphene to 50mL of ultrapure water, stir to disperse to obtain mixed solution A; add 90mg of cobalt nitrate hexahydrate, continue stirring for 30min to obtain mixed solution B, add 10mL of 50mg / mL thiourea solution dropwise to In the mixed solution B, drop the time for 3 minutes to obtain the mixed solution C; transfer the mixed solution C to the memory of polytetrafluoroethylene, package it and transfer it to the blast drying box, set the reaction temperature to 180°C, and the reaction time to 8 hours; After cooling to room temperature, collect the solid material; wash the solid material with ultrapure water, centrifuge 3-4 times, collect the solid material, and put it in a blast drying oven at 80°C for 12 hours to obtain a carbon-supported metal single-atom catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com