Preparation method of pyrite with different oxidation degrees

An oxidation degree, pyrite technology, applied in solid separation, flotation and other directions, can solve the problems of long preparation period, affecting the oxidation degree, slow oxidation rate of pure pyrite, etc., to achieve strong environmental adaptability, efficient and stable oxidation , the effect of shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

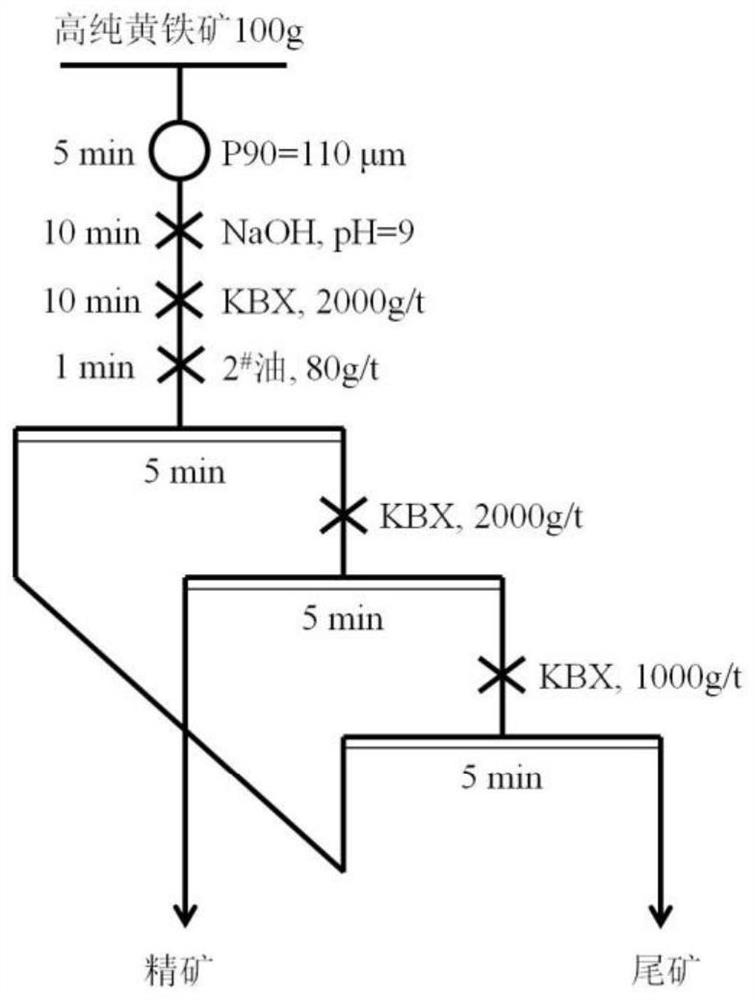

[0031] The present embodiment provides a kind of preparation method of different oxidation degree pyrite, concrete process is:

[0032] S1, the pyrite is crushed to a particle size≤2mm, then the 100g crushed sample is taken, mixed with 50ml of water and placed in a ball mill (the ball mill medium is a high chromium ball with a chromium content of 30%, and the filling rate is 32%. 47 large, medium and small balls each), grinding for 5 minutes. A pyrite powder sample with a particle size of P90≤110 μm was obtained.

[0033] S2. Collect the pyrite powder after grinding, place it in a high-speed stirrer, ensure that the solution volume is 500ml, maintain the stirrer speed at 2000r / min, feed the air at a rate of 50L / h, and continuously add a mass fraction of 30%. Hydrogen peroxide, the dosage is 1ml / min.

[0034] During the oxidation process, high-purity sodium hydroxide was used to maintain the pH of the solution system at 9, and the solution potential was maintained at 380mv (v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com