Submicron ZrC-SiC composite ceramic microsphere and preparation method thereof

A multi-phase ceramic and sub-micron technology, which is applied in the field of sub-micron ZrC-SiC multi-phase ceramic microspheres and preparation, achieves the effects of good fluidity, favorable for mass production and stable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

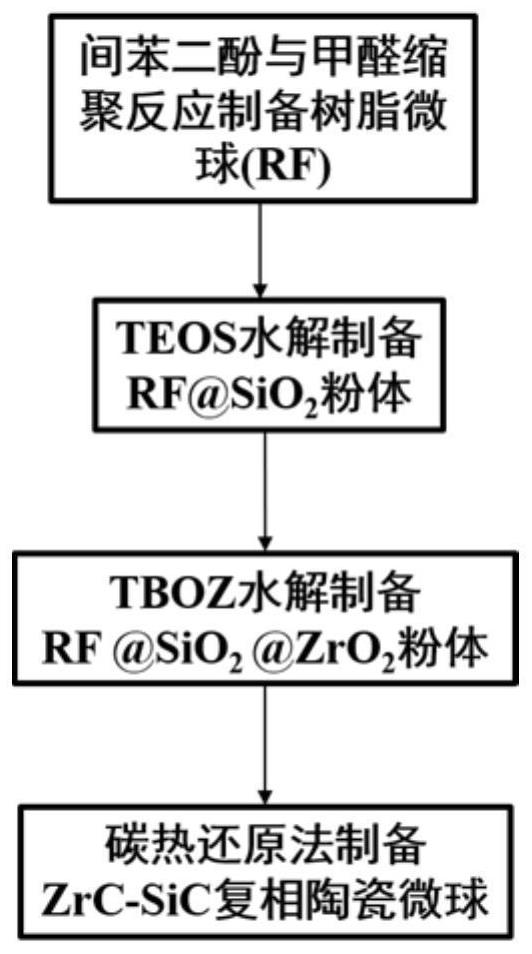

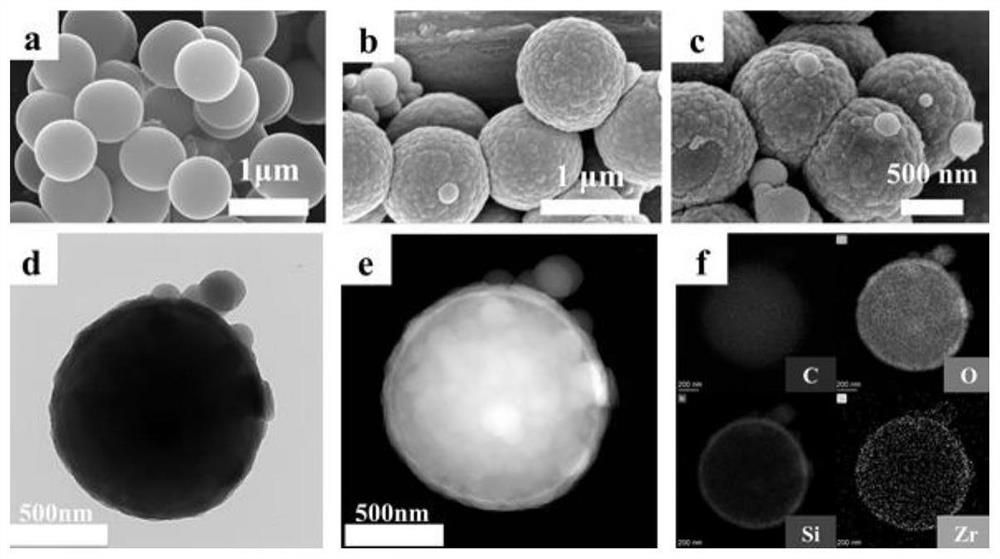

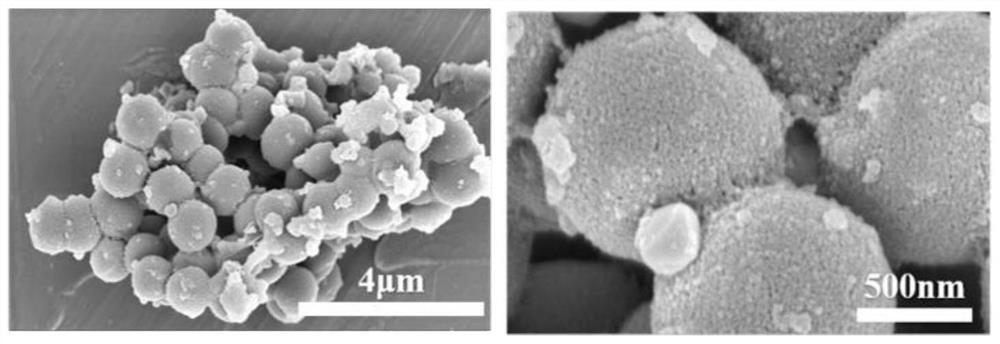

[0040] Step 1. Preparation of core-shell structure RF@SiO by template method 2 @ZrO 2 powder

[0041] Step 1.1, prepare phenolic resin (Resorcinol-formaldehyde, RF) microsphere by polycondensation reaction of resorcinol and formaldehyde: 3g resorcinol is dissolved in the mixing that contains 20ml deionized water, 250ml absolute ethanol and 10ml concentrated ammonia water In the solution, after stirring evenly, 4ml of formaldehyde solution was added dropwise, stirred in a water bath at 30°C for 12 hours, centrifuged and dried to obtain monodisperse RF microspheres.

[0042] Step 1.2, preparing silica-coated phenolic resin core-shell structure powder RF@SiO by the Stober method 2 : Put 0.3g of RF microspheres prepared in step 1.1 into a mixed solution containing 20ml of deionized water, 75ml of absolute ethanol, 3ml of ammonia water and 0.6g of cetyltrimethylammonium bromide, ultrasonically disperse, and then drop Add 1 ml of ethyl orthosilicate. Stir in a water bath at 30°C...

Embodiment 2

[0047] Step 1.1, prepare phenolic resin (Resorcinol-formaldehyde, RF) microsphere by polycondensation reaction of resorcinol and formaldehyde: 3g resorcinol is dissolved in the mixing that contains 20ml deionized water, 250ml absolute ethanol and 10ml concentrated ammonia water In the solution, after stirring evenly, 4ml of formaldehyde solution was added dropwise, stirred in a water bath at 30°C for 12 hours, centrifuged and dried to obtain monodisperse RF microspheres.

[0048] Step 1.2, prepare silica-coated phenolic resin core-shell structure powder RF@SiO2 by the Stober method: put 0.3g of RF microspheres prepared in step 1.1 into a solution containing 20ml of deionized water, 75ml of absolute ethanol, and 3ml of ammonia water And in the mixed solution of 0.6g cetyltrimethylammonium bromide, after ultrasonic dispersion, 1ml tetraethyl orthosilicate was added dropwise. Stir in a water bath at 30°C for 20 hours, centrifuge and dry to obtain RF@SiO 2 Powder.

[0049] Step ...

Embodiment 3

[0053] Step 1.1, prepare phenolic resin (Resorcinol-formaldehyde, RF) microsphere by polycondensation reaction of resorcinol and formaldehyde: 4g resorcinol is dissolved in the mixing that contains 20ml deionized water, 250ml absolute ethanol and 10ml concentrated ammonia water In the solution, after stirring evenly, 6ml of formaldehyde solution was added dropwise, stirred in a water bath at 30°C for 12 hours, centrifuged and dried to obtain monodisperse RF microspheres.

[0054] Step 1.2, preparing silica-coated phenolic resin core-shell structure powder RF@SiO by the Stober method 2 : Put 0.3g of RF microspheres prepared in step 1.1 into a mixed solution containing 20ml of deionized water, 75ml of absolute ethanol, 3ml of ammonia water and 0.6g of cetyltrimethylammonium bromide, ultrasonically disperse, and then drop Add 1 ml of ethyl orthosilicate. Stir in a water bath at 30°C for 24 hours, centrifuge and dry to obtain RF@SiO 2 Powder.

[0055] Step 1.3, 0.20g of RF@SiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com