Heterogeneous integration method for monocrystalline two-dimensional semiconductor molybdenum telluride film and arbitrary lattice mismatched monocrystalline substrate

A two-dimensional semiconductor and lattice-mismatching technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, sustainable manufacturing/processing, etc., can solve problems that hinder the development of related devices, complex processes, and high cost of buffer layer technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

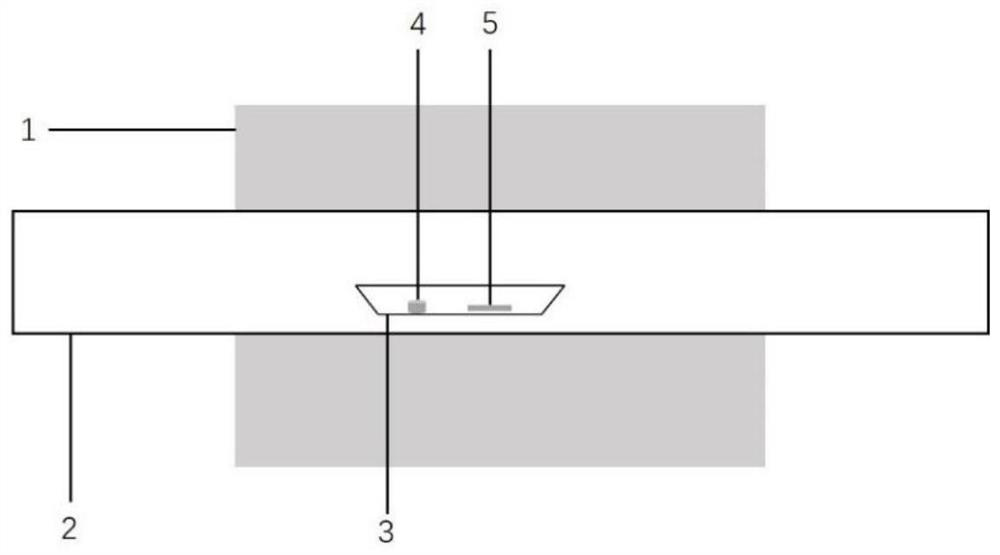

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

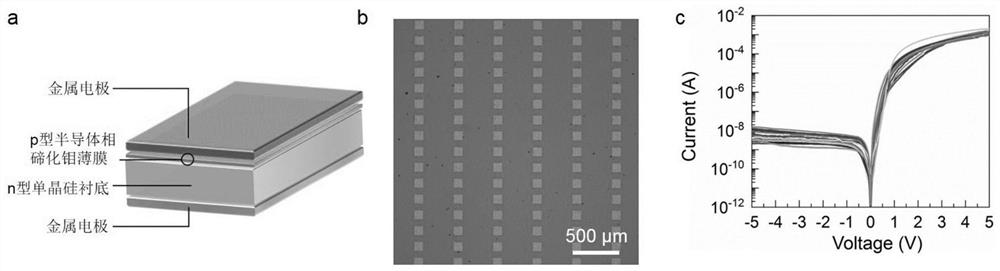

[0024] In this example, a pn junction device that is heterogeneously integrated with a two-dimensional semiconductor molybdenum telluride thin film and a variety of lattice-mismatched three-dimensional single crystal materials is prepared through the following steps:

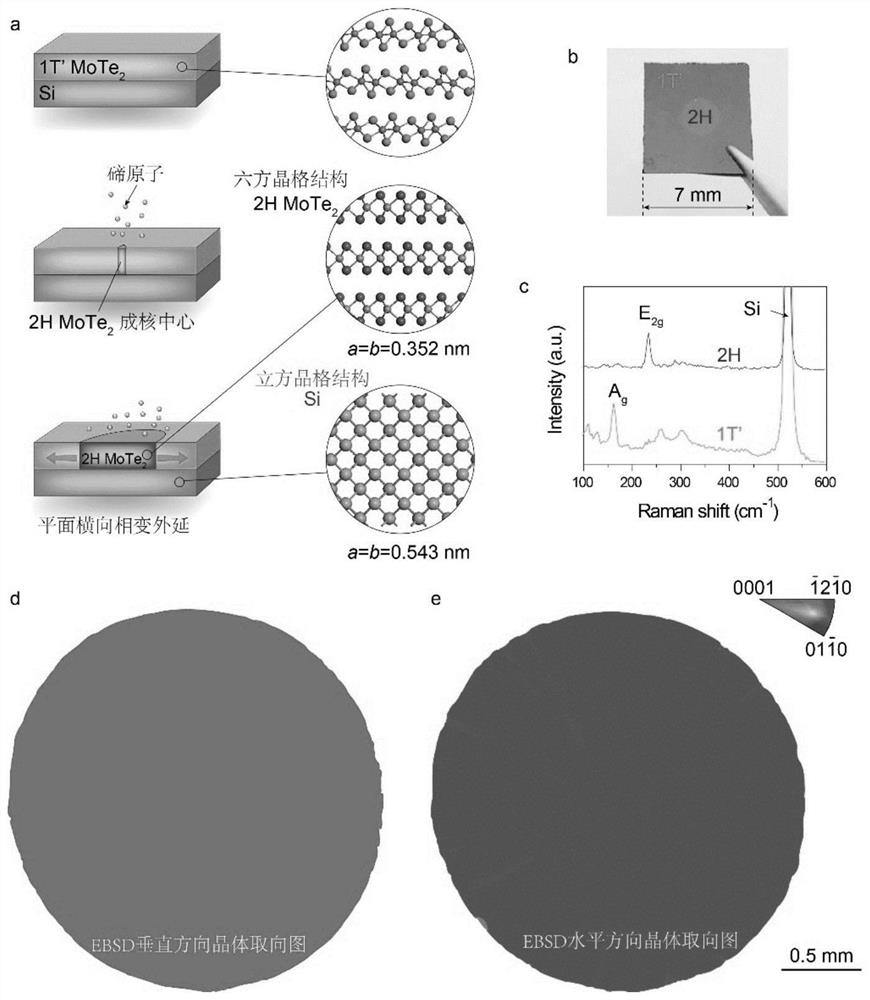

[0025] (1) Three-dimensional single-crystal substrate material preparation. In order to demonstrate the advantage that two-dimensional single-crystal semiconductor molybdenum telluride thin films can be directly grown on single-crystal materials with mismatched lattice structures, we selected molybdenum telluride thin films (hexagonal lattice structure) Different single crystal silicon materials are used as substrates (cubic lattice structure), and the crystal plane is [001]. The lattice constant of semiconductor molybdenum telluride is a=b=0.352nm, the lattice constant of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com