PtFe-SiO2 nano composite material as well as preparation method and application thereof

A nanocomposite material, ptfe-sio2 technology, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of large size, low atom utilization, easy agglomeration and deactivation, etc., and achieve high selectivity and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] This application also provides PtFe-SiO 2 The preparation method of nanocomposite material, comprises the following steps:

[0028] Mix iron source, platinum source and water to obtain mixed solution A;

[0029] Mixing the mixed solution A with fumed silica to obtain a gel B;

[0030] The gel material B is ground, dried, calcined, and finally reduced to obtain PtFe-SiO 2 nanocomposites.

[0031] In this application provided the PtFe-SiO 2 In the preparation method of nanocomposites, the iron source and the platinum source are iron sources and platinum sources well known to those skilled in the art, and the present application is not particularly limited. For example, the iron source is selected from nonahydrate One or more of ferric nitrate, ferric chloride hexahydrate and ferric sulfate hydrate, and the platinum source is selected from one or more of tetraammine platinum nitrate, chloroplatinic acid and ammonium chloroplatinate. The ratio of the iron source, the p...

Embodiment 1

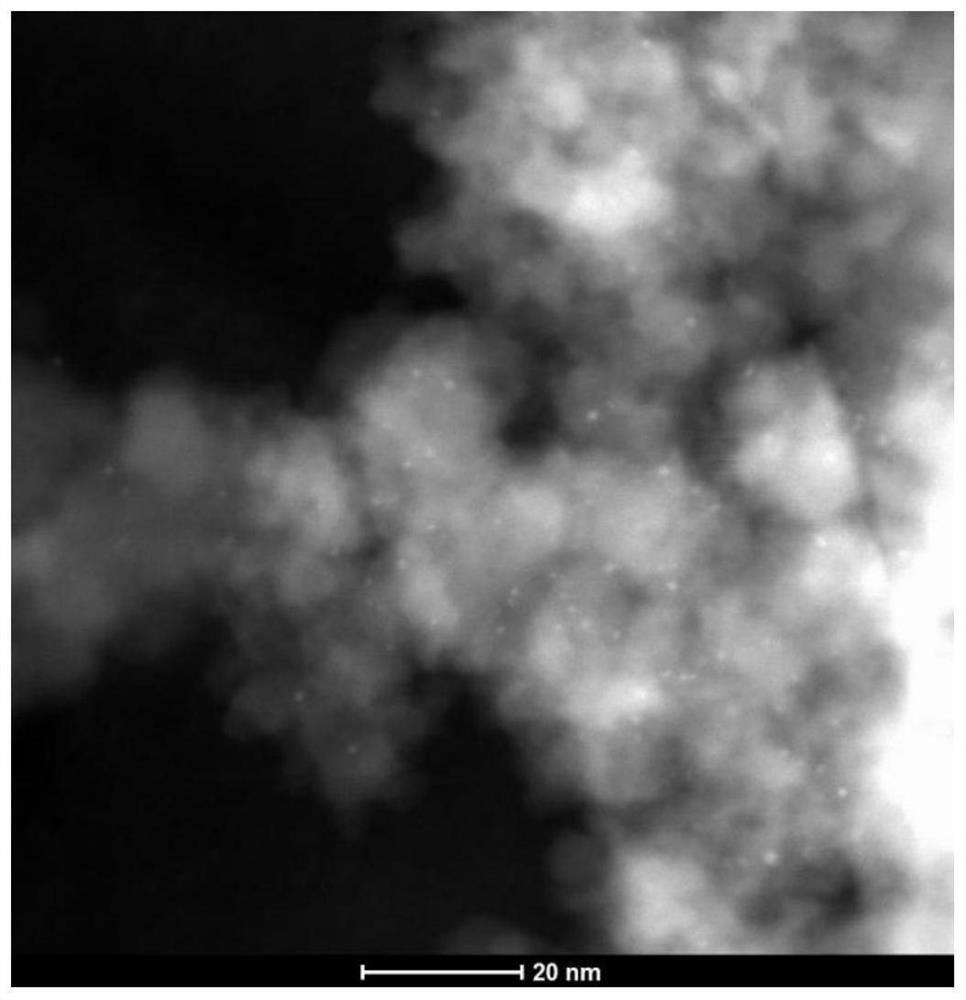

[0039] At room temperature, take 500 mg of gas-phase SiO 2 Put it aside for use, dissolve 20.2mg of ferric nitrate nonahydrate and 1.96mg of tetraammine platinum nitrate in 1mL of deionized water, ultrasonically evenly, and drop the mixed solution into the gas phase SiO 2 and then use a glass rod to stir evenly to obtain a gel, place the gel overnight to dry and grind it to a solid powder, dry the solid powder in an oven at 60°C for 12 hours, and put the dried solid powder into a muffle furnace Calcination treatment, the calcination temperature is 573K, the heating rate is 5K / min, the calcination time is 1h, and the calcined solid powder is heated in 10% H 2 Under the atmosphere condition of +90% Ar (volume percent), reduction treatment is carried out, the reduction temperature is 873K, the heating rate is 10K / min, and the reduction time is 3h, and the SiO in the gas phase is obtained. 2 impregnated Pt-Fe nanocatalysts.

[0040] The composition of the catalyst that above-men...

Embodiment 2

[0042] At room temperature, take 500 mg of gas-phase SiO 2 Put it aside for use, dissolve 1.96mg tetraammineplatinum nitrate in 1mL deionized water, sonicate evenly, and drop the mixed solution evenly into the gas phase SiO 2 and then use a glass rod to stir evenly to obtain a gel, place the gel overnight to dry and grind it to a solid powder, dry the solid powder in an oven at 60°C for 12 hours, and put the dried solid powder into a muffle furnace Calcination treatment, the calcination temperature is 573K, the heating rate is 5K / min, the calcination time is 1h, and the calcined solid powder is heated in 10% H 2 Under the atmosphere condition of +90% Ar (volume percent), reduction treatment is carried out, the reduction temperature is 873K, the heating rate is 10K / min, and the reduction time is 3h, and the SiO in the gas phase is obtained. 2 impregnated Pt nanocatalysts.

[0043] The composition of the catalyst that above-mentioned preparation method obtains is 0.2wt%Pt / SiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com