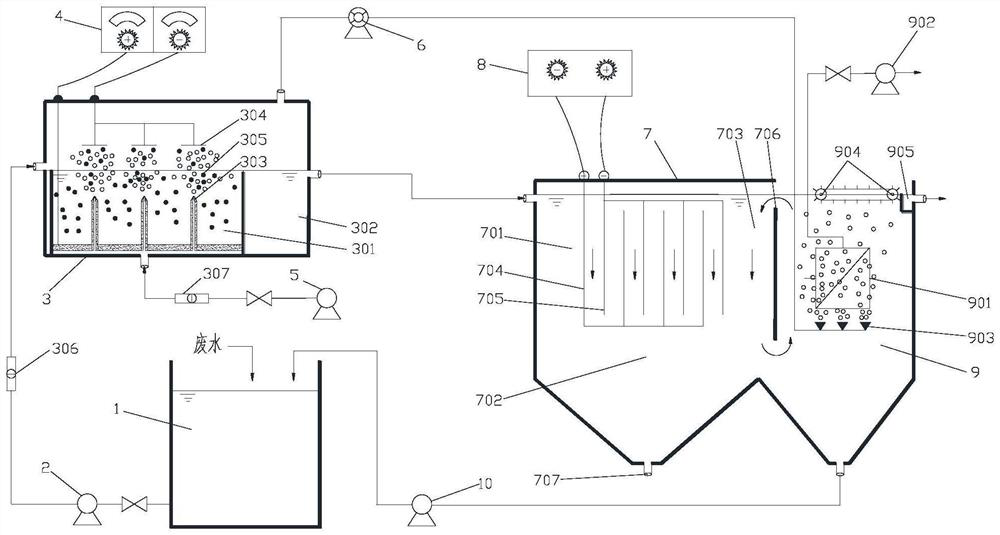

System and method for treating polymer-containing and glue-containing wastewater through plasma combination

A plasma and wastewater technology, which is applied in mining wastewater treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve problems such as difficult effective penetration, poor mud-water separation effect in subsequent processes, and large dosage of chemicals. , to achieve the effect of improving destabilization efficiency, strengthening pollutant degradation and gel breaking ability, and reducing wastewater viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A large amount of fracturing flowback fluid and production water are produced during the exploitation of a certain coalbed methane in Shanxi Province. The wastewater contains a large amount of polymers and colloids, and has a high salinity. With the increase of gas production, the volume of production water and fracturing flowback fluid is getting higher and higher, and the volume and quality of wastewater fluctuate greatly. The existing treatment process and effluent water quality are facing great challenges. In order to meet the production needs, it is planned to upgrade the existing process to improve the processing efficiency.

[0033] Adopt the plasma combined process of the present invention to carry out 480m to this polymer-containing glue-containing wastewater 3 / d engineering application, the average mass concentration of COD in wastewater is 2285mg / L, the average mass concentration of SS is 3430mg / L, the average mass concentration of oil content is 42mg / L, the...

Embodiment 2

[0035] An oil production terminal in Qinghai Province adopts a combined process of coagulation sedimentation + air flotation + precision filtration to treat oily production water. With the in-depth development of the oil field and the optimization of the production process, the produced water contains a large amount of polymers, colloids and inorganic salts. There is a large amount of dosing in the treatment process, frequent clogging of the precision filter unit, unstable operation of the treatment process and frequent load shocks to the system, large fluctuations in effluent quality, and greater pressure on environmental protection for enterprises.

[0036] The 1 m of the polymer-containing glue-containing production wastewater was carried out by adopting the plasma combined process of the present invention 3 / h pilot test, the average mass concentration of wastewater COD is 1532mg / L, NH 4 + - The average mass concentration of N is 68mg / L, the average mass concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com