A kind of retarded setting magnesium potassium phosphate cement and preparation method thereof

A technology of retarded magnesium phosphate and potassium dihydrogen phosphate, which is applied in the field of building materials, can solve the problems of reduced strength and water resistance, application limitations, difficult control of retarder dosage, etc., and achieves short setting time and simple preparation method , the effect of controllable coagulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

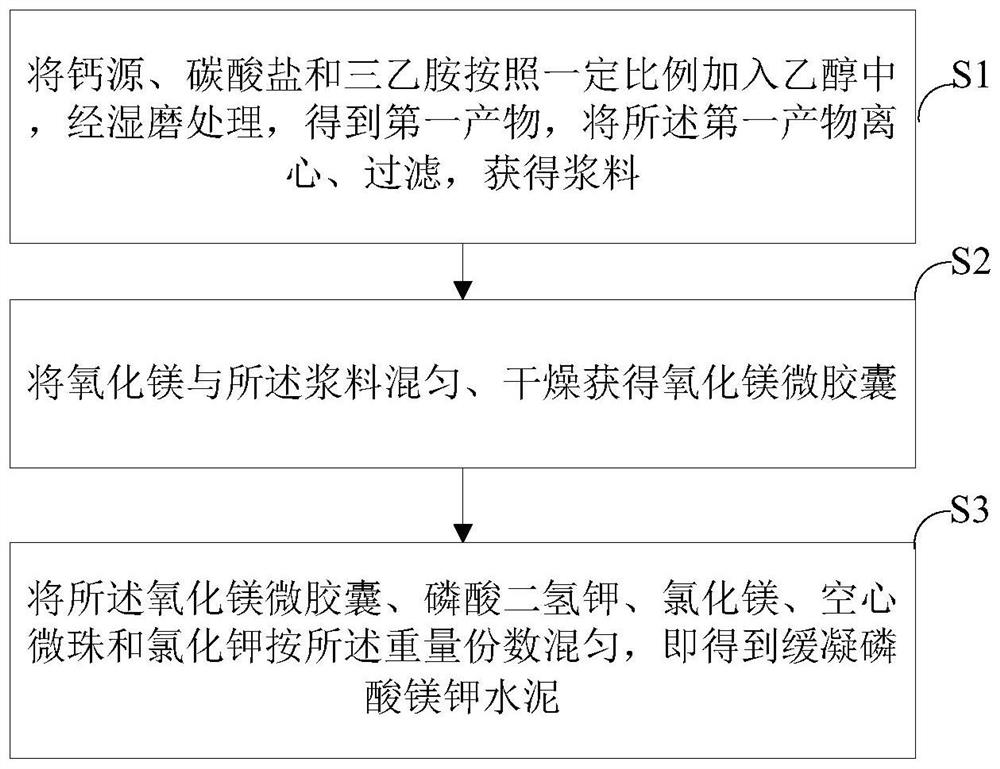

Method used

Image

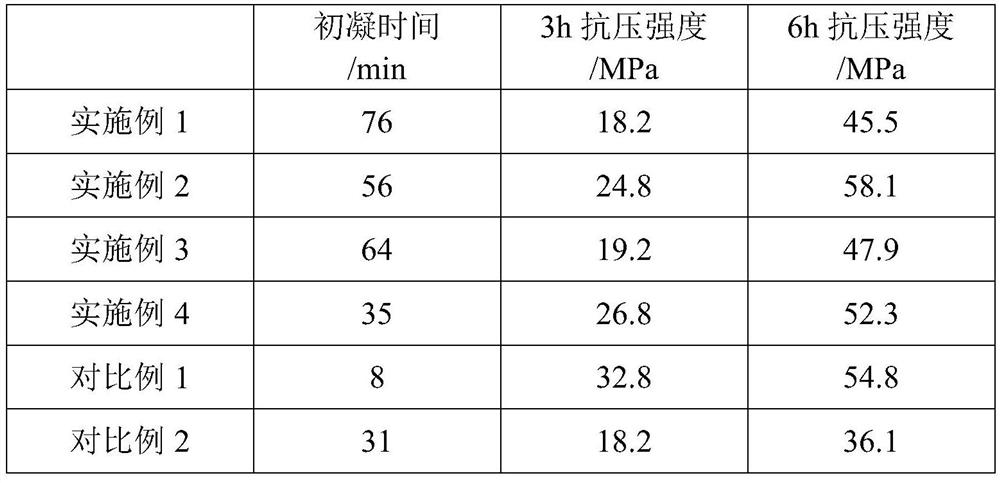

Examples

Embodiment 1

[0044] A kind of retarded setting magnesium potassium phosphate cement is prepared according to the following steps:

[0045] (1) Add ethanol in the wet ball mill, then add calcium chloride, potassium carbonate and triethylamine by weight 1:1:100 into the wet ball mill and mix evenly, calcium chloride, potassium carbonate and triethylamine are mixed. The weight ratio of the sum of weights to ethanol is 20:100;

[0046] (2) After wet grinding, the slurry is obtained by centrifugal filtration. In the wet grinding process, the temperature of the outer wall of the ball mill is controlled by water cooling or liquid nitrogen to be less than or equal to 50°C;

[0047] (3) fully stirring the magnesium oxide and the slurry at 1:100 by mass, and drying in the air to obtain the magnesium oxide microcapsules;

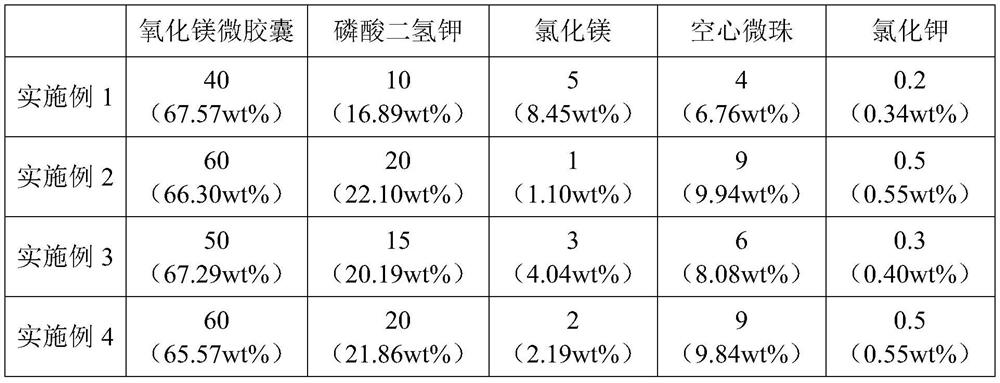

[0048] (4) place the cement mortar mixer according to the parts by weight of the raw materials shown in table 1, magnesium oxide microcapsules, potassium dihydrogen phosphate, mag...

Embodiment 2

[0050] A kind of retarded setting magnesium potassium phosphate cement is prepared according to the following steps:

[0051] (1) Add ethanol in the wet ball mill, then add calcium chloride, potassium carbonate and triethylamine to the wet ball mill at 1:1:60 by weight and mix them evenly. The weight ratio of the sum of weights to ethanol is 15:100;

[0052] (2) After wet grinding, the slurry is obtained by centrifugal filtration. In the wet grinding process, the temperature of the outer wall of the ball mill is controlled by water cooling or liquid nitrogen to be less than or equal to 50°C;

[0053] (3) fully stirring the magnesium oxide and the slurry at 1:100 by mass, and drying in the air to obtain the magnesium oxide microcapsules;

[0054] (4) place the cement mortar mixer according to the parts by weight of the raw materials shown in table 1, magnesium oxide microcapsules, potassium dihydrogen phosphate, magnesium chloride, hollow microbeads and potassium chloride, sti...

Embodiment 3

[0056] A kind of retarded setting magnesium potassium phosphate cement is prepared according to the following steps:

[0057] (1) Add ethanol in the wet ball mill, then add calcium chloride, potassium carbonate and triethylamine by weight 1:1:100 into the wet ball mill and mix evenly, calcium chloride, potassium carbonate and triethylamine are mixed. The weight ratio of the sum of weights to ethanol is 10:100;

[0058] (2) After wet grinding, the slurry is obtained by centrifugal filtration. In the wet grinding process, the temperature of the outer wall of the ball mill is controlled by water cooling or liquid nitrogen to be less than or equal to 50°C;

[0059] (3) fully stirring the magnesium oxide and the slurry at 1:100 by mass, and drying in the air to obtain the magnesium oxide microcapsules;

[0060] (4) place the cement mortar mixer according to the parts by weight of the raw materials shown in table 1, magnesium oxide microcapsules, potassium dihydrogen phosphate, mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com