Magnetic card protecting film and preparation method thereof

A card protection film and magnetic technology, which is applied in the field of card protection film, can solve the problems of poor anti-aging and achieve the effects of improving anti-aging, high dimensional stability, and high anti-light aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The magnetic card protection film of embodiment 1 is obtained by following operation steps:

[0039] According to the dosage in Table 1, the preparation of BOPET base film: mix polyethylene terephthalic acid resin, samarium cobalt magnetic powder, nano-titanium dioxide, 4-hydroxybenzophenone, organic nickel chelate, glycidyl methacrylate Uniform, melt-extruded at 240°C, cast into sheets, made into polyester chips, polymerized, crystallized, dried, biaxially stretched, and corona surface treated to obtain BOPET base film;

[0040] According to the dosage in Table 2, mix ethylene-ethyl acrylate copolymer, 2,6-di-tert-butyl-p-cresol, phosphite and polyethylene naphthalate, stir evenly, and cast To the surface of the high-temperature BOPET base layer, laminated and cooled to form a protective card film.

Embodiment 2-5

[0042] The preparation method and raw material types of the magnetic card protection film of Examples 2-5 are exactly the same as those of Example 1, the difference is that the dosage of each raw material is different, as shown in Table 1 and Table 2 for details.

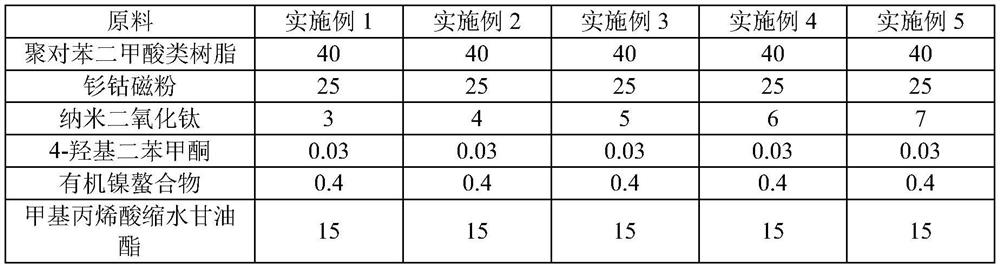

[0043] Table 1 embodiment 1-5 each raw material dosage of BOPET base film of magnetic card protection film

[0044] (unit: kg)

[0045]

[0046] Table 2 embodiment 1-5 each raw material dosage of magnetic card protection film EEA adhesive layer

[0047] (unit: kg)

[0048] raw material Example 1 Example 2 Example 3 Example 4 Example 5 Ethylene-ethyl acrylate copolymer 35 35 35 35 35 2,6-di-tert-butyl-p-cresol 0.5 0.7 0.8 0.9 1.0 Phosphite 0.1 0.1 0.1 0.1 0.1 polyethylene naphthalate 0.1 0.1 0.1 0.1 0.1

Embodiment 6-9

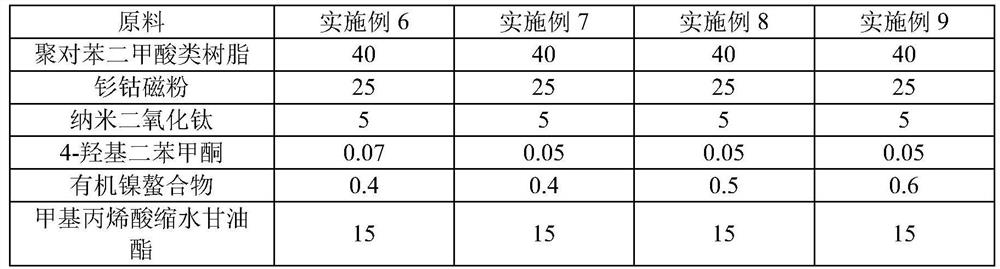

[0050] The preparation method and raw material types of the magnetic card protection film of Examples 6-9 are exactly the same as those of Example 3, the difference is that the dosage of each raw material of the BOPET base film is different, as shown in Table 3 for details.

[0051] Table 3 Embodiment 6-9 The dosage of each raw material of the magnetic card protection film BOPET base film

[0052] (unit: kg)

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com