Environment-friendly pressure-sensitive adhesive with good bonding effect and preparation method thereof

A pressure-sensitive adhesive and environmentally friendly technology, which is applied in the field of pressure-sensitive adhesives, can solve the problems of easy fogging of the laminate, limit the application range of latex rubber pressure-sensitive adhesives, weak initial adhesion and peel strength, and achieve improved peel strength, Improves water resistance and adhesion, improves anti-aging performance and heat-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

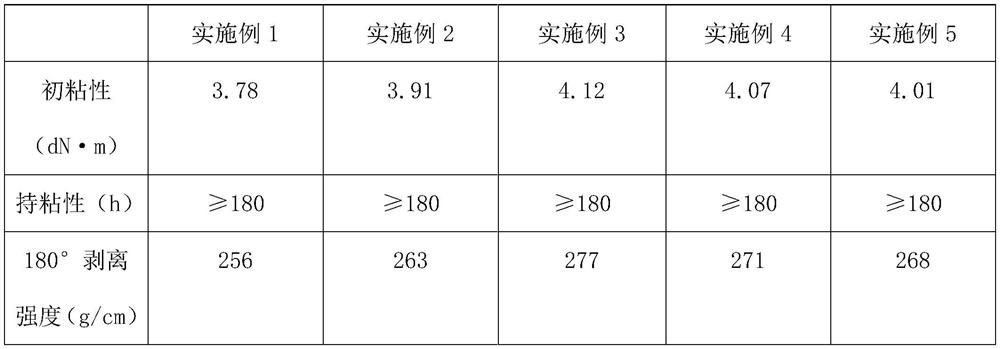

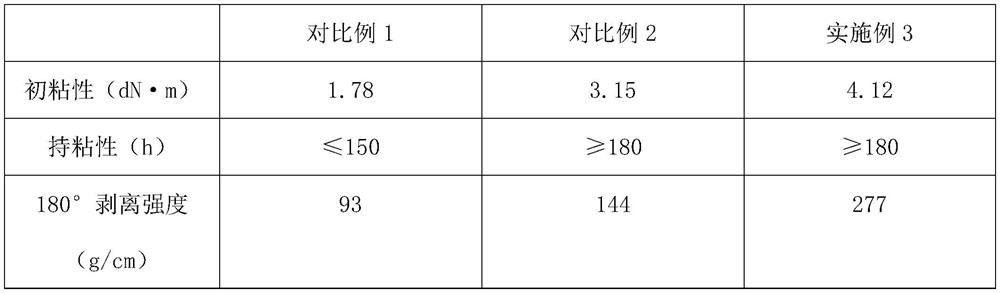

Examples

Embodiment 1

[0026] Embodiment 1 An environmentally friendly pressure-sensitive adhesive with good bonding effect and a preparation method thereof, comprising:

[0027] 1. Preparation of enhancer

[0028] 1. Add 20 parts of paraffin wax into the reaction kettle to heat and melt, then add 1 part of dodecylphenol polyoxyethylene ether and 20 parts of piperylene petroleum resin and mix evenly to prepare the oil phase mixture;

[0029] 2. Preheat the deionized water, then pour it into the oil phase mixture, and stir quickly;

[0030] 3. Then add 10 parts of acrylic acid and stir quickly, pour out the remaining deionized water after emulsification, and cool down to prepare the enhancer.

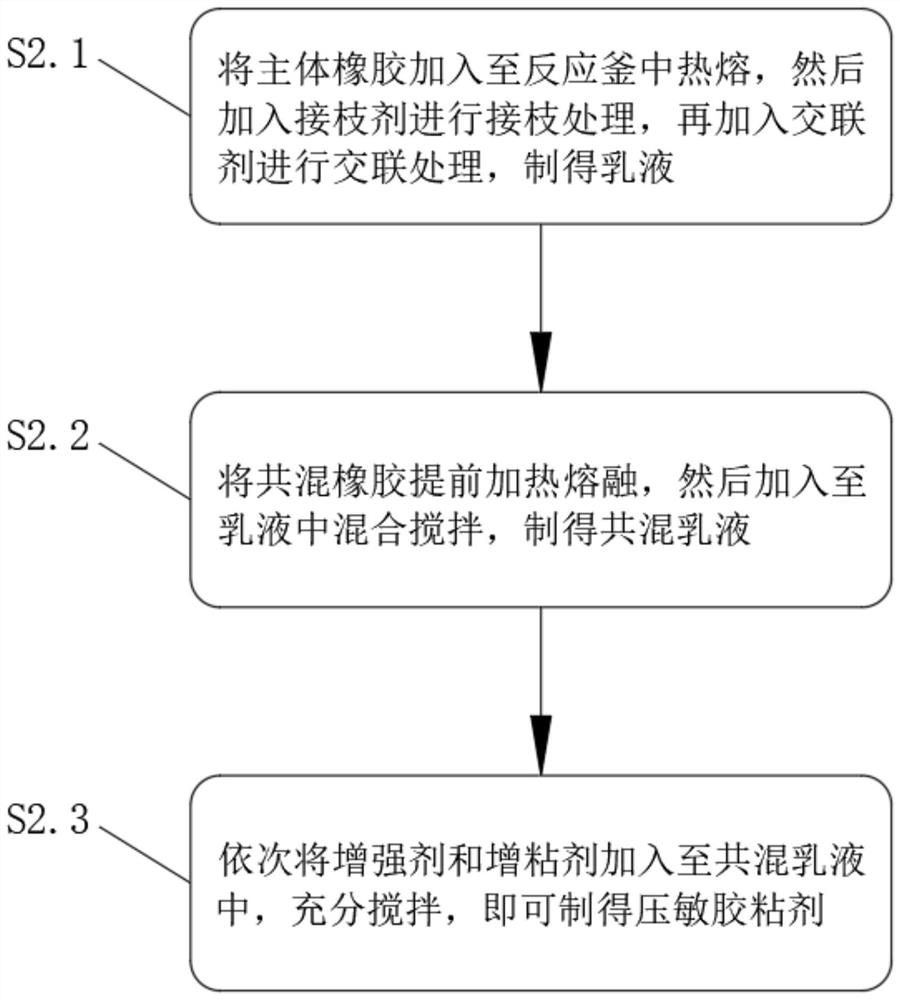

[0031] 2. Preparation of pressure sensitive adhesive

[0032] 1. Add 80 parts of the main rubber to the reaction kettle for hot melting, then add 1 part of grafting agent for grafting treatment, and then add 1 part of crosslinking agent for crosslinking treatment to obtain an emulsion;

[0033] 2. Heat and ...

Embodiment 2

[0035] Embodiment 2 An environmentally friendly pressure-sensitive adhesive with good bonding effect and a preparation method thereof, comprising:

[0036] 1. Preparation of enhancer

[0037] 1. Add 23 parts of paraffin wax into the reaction kettle and heat and melt, then add 1 part of dodecylphenol polyoxyethylene ether and 23 parts of piperylene petroleum resin and mix evenly to prepare the oil phase mixture;

[0038] 2. Preheat the deionized water, then pour it into the oil phase mixture, and stir quickly;

[0039] 3. Then add 12 parts of acrylic acid and stir quickly, pour out the remaining deionized water after emulsification, and cool down to prepare the enhancer.

[0040] 2. Preparation of pressure sensitive adhesive

[0041] 1. Add 90 parts of the main rubber to the reactor for hot melting, then add 2 parts of grafting agent for grafting treatment, and then add 2 parts of crosslinking agent for crosslinking treatment to obtain an emulsion;

[0042] 2. Heat and melt ...

Embodiment 3

[0044] Embodiment 3 An environmentally friendly pressure-sensitive adhesive with good bonding effect and a preparation method thereof, comprising:

[0045] 1. Preparation of enhancer

[0046] 1. Add 25 parts of paraffin wax into the reaction kettle and heat and melt, then add 2 parts of dodecylphenol polyoxyethylene ether and 25 parts of piperylene petroleum resin and mix evenly to prepare the oil phase mixture;

[0047] 2. Preheat the deionized water, then pour it into the oil phase mixture, and stir quickly;

[0048] 3. Then add 13 parts of acrylic acid and stir quickly, pour out the remaining deionized water after emulsification, and cool down to prepare the enhancer.

[0049] 2. Preparation of pressure sensitive adhesive

[0050] 1. Add 100 parts of the main rubber to the reactor for hot melting, then add 3 parts of grafting agent for grafting treatment, and then add 3 parts of crosslinking agent for crosslinking treatment to obtain an emulsion;

[0051] 2. Heat and mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial tack | aaaaa | aaaaa |

| Initial tack | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com