Method for extracting human antithrombin III from plasma

An antithrombin and plasma technology, applied in the field of biopharmaceuticals, can solve the problems of human antithrombin III remaining in laboratory development, failing to obtain new drug certificates and production approvals, and late production research, etc., and reduce chromatography. System and supporting facilities and site equipment, good virus filtering effect, high security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

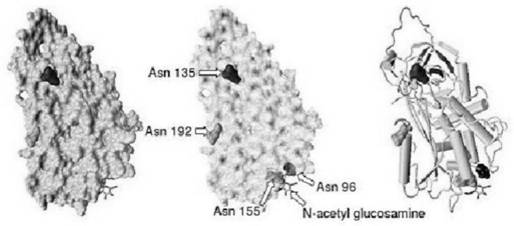

Image

Examples

Embodiment 1

[0038] (1) Removal of cryoprecipitate from fresh frozen human plasma: take 500L of fresh frozen human plasma, melt and mix evenly, remove cryoprecipitate through a flow centrifuge, and obtain plasma supernatant after centrifugation;

[0039] (2) DEAE Sephadex A-50 gel adsorption: Add DEAE Sephadex A-50 gel to the plasma supernatant obtained in step (1), the amount of dry gel added is 500g, and the dry gel is pre-treated with a temperature above 70°C Swell with hot water for injection, then cool with cold water for injection below 25°C, and finally balance with equilibrium buffer, stir for 1.0 hour at an appropriate speed (to ensure that the gel is evenly mixed and distributed in the solution and not too fast), filter to obtain the filtrate, and condense The gel can be reused after being regenerated; the balance buffer formula is: 0.02M sodium citrate, 0.2M sodium chloride, pH 7.0

[0040] (3) Polyethylene glycol (PEG-4000) purification treatment: adjust the pH of the filtrate ...

Embodiment 2

[0050] (1) Removal of cryoprecipitate from fresh frozen human plasma: take 800L of fresh frozen human plasma, melt and mix evenly, remove cryoprecipitate through a flow centrifuge, and obtain plasma supernatant after centrifugation;

[0051] (2) DEAE Sephadex A-50 gel adsorption: Add DEAE Sephadex A-50 gel to the plasma supernatant obtained in step (1), the amount of dry gel added is 960g, and the dry gel is pre-heated with a temperature above 70°C Swell with hot water for injection, then cool with cold water for injection below 25°C, and finally balance with equilibrium buffer, stir for 1.5 hours at an appropriate speed (to ensure that the gel is evenly mixed and distributed in the solution and not too fast), filter to obtain the filtrate, and condense The gel can be reused after being regenerated; the equilibrium buffer formula is: 0.015M sodium citrate, 0.2M sodium chloride, pH 7.5

[0052] (3) Polyethylene glycol (PEG-4000) purification treatment: adjust the pH of the filt...

Embodiment 3

[0062] (1) Remove cryoprecipitate from fresh frozen human plasma: take 1000L fresh frozen human plasma, melt and mix evenly, remove cryoprecipitate through a flow centrifuge, and obtain plasma supernatant after centrifugation;

[0063] (2) DEAE Sephadex A-50 gel adsorption: Add DEAE Sephadex A-50 gel to the plasma supernatant obtained in step (1). Swell with hot water for injection, then cool with cold water for injection below 25°C, and finally balance with equilibrium buffer, stir for 2 hours at an appropriate speed (to ensure that the gel is evenly mixed and distributed in the solution and not too fast), filter to obtain the filtrate, and condense The gel can be reused after being regenerated; the equilibrium buffer formula is: 0.015M sodium citrate, 0.2M sodium chloride, pH 7.5

[0064] (3) Polyethylene glycol (PEG-4000) purification treatment: adjust the pH of the filtrate obtained in step (2) to 6.5, add 15% (w / v) polyethylene glycol (PEG-4000), and centrifuge to remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com