Dechlorinating agent as well as preparation method and application thereof

A chlorine removal agent and contact reaction technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of high chlorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The second aspect of the present application provides a preparation method of a chlorine removal agent, and is prepared in the following manner:

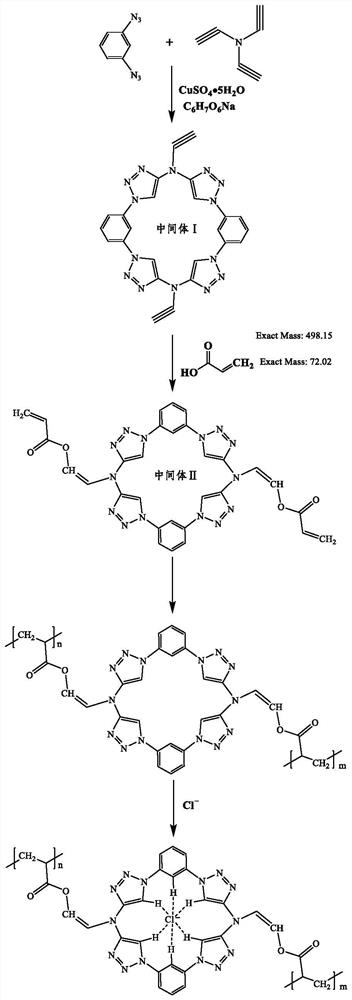

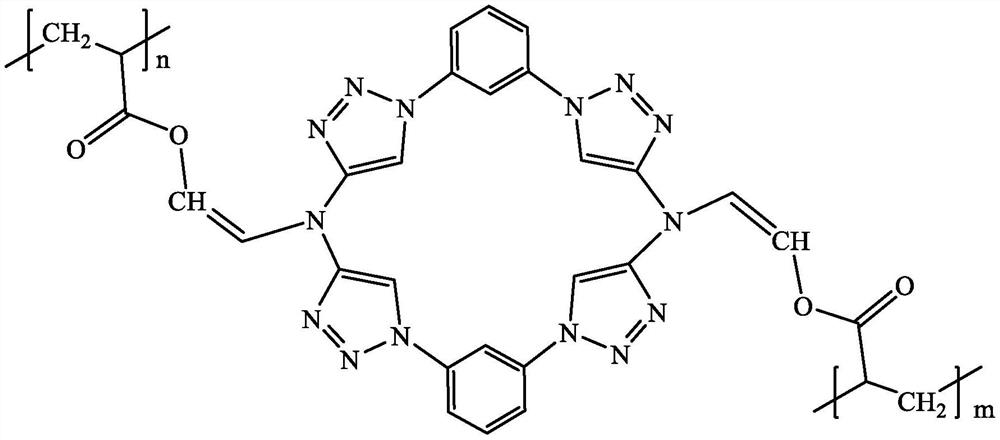

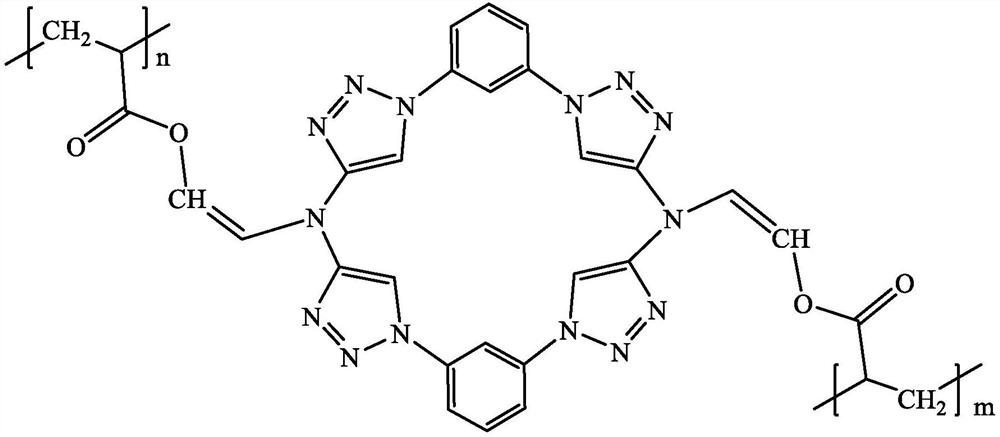

[0045] Firstly, using triethynylamine and meta-azidobenzene as raw materials, using copper sulfate pentahydrate and sodium ascorbate as catalysts, the intermediate I was obtained through the click reaction of azide and alkyne, and then the intermediate I was obtained by the addition reaction of alkyne and carboxyl groups. The terminal double bond intermediate II is finally used to obtain the recyclable chlorine removal agent by self-polymerization of the intermediate II.

[0046] Please refer to the attached figure 1 , with figure 1 The synthesis and dechlorination mechanism diagram of the dechlorination agent provided for the embodiment of the application, such as figure 1 Shown, the preparation method of this chlorine removal agent may further comprise the steps:

[0047] 1) Add a mixed liquid of water and tert-butanol i...

Embodiment 1

[0052] Add 61.34g of mixed solvent (the mass ratio of water and tert-butanol is 1:1) into a three-necked flask equipped with a stirrer, and then add 9.96g of catalyst (the molar ratio of copper sulfate pentahydrate and sodium ascorbate is 1:2) , the temperature was raised to 60°C. Then 8.9g (0.1mol) of triethynylamine and 16g (0.1mol) of m-azidobenzene were dissolved in 20g of mixed solvent, and slowly added dropwise to the three-necked flask, the dropping time was kept at 5h, and the reaction was carried out for 10h, under the protection of argon throughout the process. . After the reaction was completed, it was cooled to room temperature, extracted with dichloromethane, separated to obtain an organic phase, dried with anhydrous sodium sulfate, filtered, and then rotary evaporated to remove the dichloromethane to obtain intermediate I.

[0053] Dissolve 24.9 (0.05mol) of intermediate I and 7.2 (0.1mol) of acrylic acid in 48.15g of acetone and place them in the reactor, add 0...

Embodiment 2

[0056] Add 140g mixed solvent (the mass ratio of water and tert-butanol is 1:1) in the there-necked flask equipped with stirrer, then add 13.34g catalyst (wherein the mol ratio of copper sulfate pentahydrate and sodium ascorbate is 1:2), The temperature increased to 65°C. Then 10.68g (0.12mol) of triethynylamine and 16g (0.1mol) of m-azidobenzene were dissolved in 20g of mixed solvent, and slowly added dropwise to the three-necked flask, the dropping time was kept at 6h, the reaction was 13h, and the whole process was protected by argon. . After the reaction was completed, it was cooled to room temperature, extracted with dichloromethane, separated to obtain an organic phase, dried with anhydrous sodium sulfate, filtered, and then rotary evaporated to remove the dichloromethane to obtain intermediate I.

[0057] Dissolve 24.9 (0.05mol) of intermediate I and 7.92 (0.11mol) of acrylic acid in 76.58g of acetone and place them in a reactor, add 1.64g of sodium hydroxide as a cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com