Wear-resistant rubber material and preparation method thereof

A technology of wear-resistant rubber and wear-resistant carbon black, which is applied in the field of low-friction rubber materials in a wide temperature range and its preparation, and can solve problems such as increased free travel of the steering wheel, wear of the ball bowl, and abnormal noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

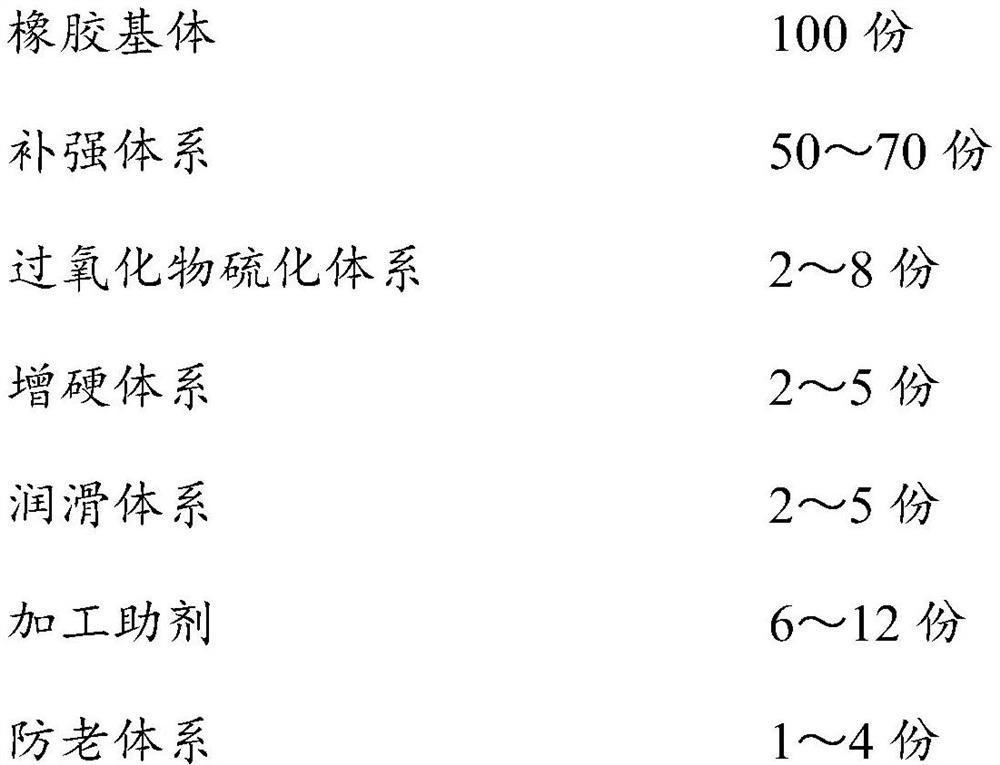

[0033] A wear-resistant rubber material, the rubber matrix is nitrile rubber with an acrylonitrile content of 25%, the reinforcement system is a mixture of super wear-resistant carbon black N220 and quick-press furnace black N550, the vulcanization system is vulcanizing agent BIBP, and the lubrication system is Ethylene bisoleic acid amide, the hardening system is zinc methacrylate, the processing aid is alkylphenol formaldehyde resin and fluidity dispersant RL-22, the anti-aging system is anti-aging agent NAPM, in parts by mass, the content of each component for:

[0034]

[0035]

[0036] A preparation method of a wear-resistant rubber material, the specific steps are as follows:

[0037] Plasticize the raw rubber on the open mill, then heat the glue in the internal mixer to a temperature of 70 ° C ~ 90 ° C (without cooling water), add the mixture of super wear-resistant carbon black N220 and fast extrusion furnace black N550 in 4 times , until the mixing is uniform...

Embodiment 2

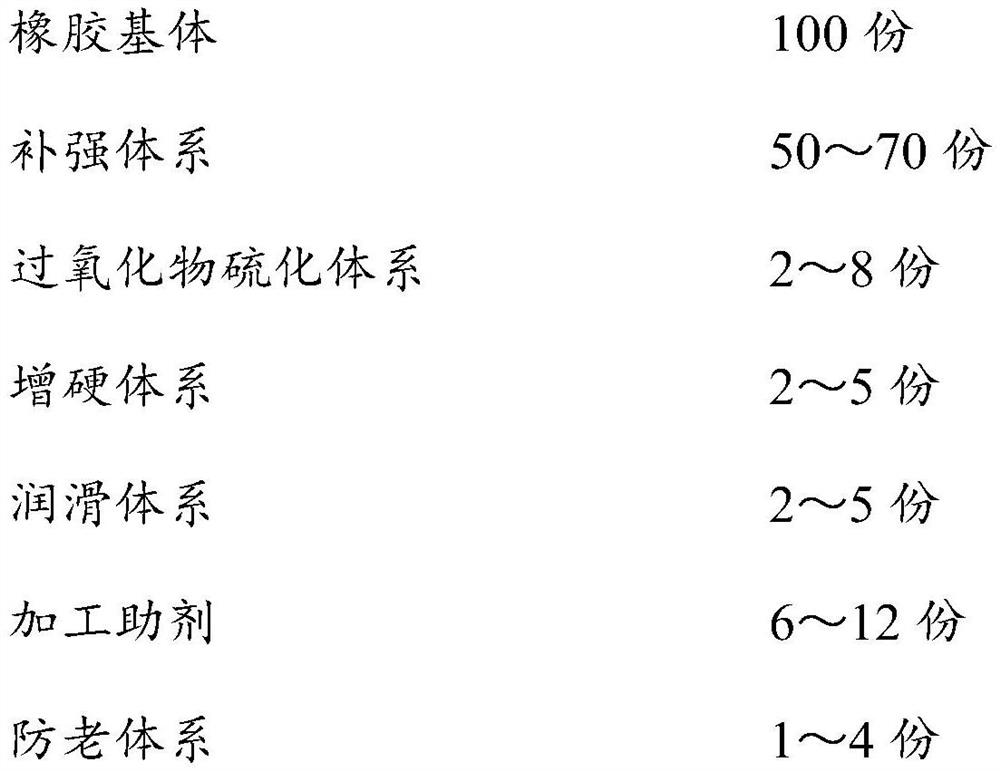

[0039] A wear-resistant rubber material, the rubber matrix is nitrile rubber with an acrylonitrile content of 35%, the reinforcing system is super wear-resistant carbon black N220, the vulcanizing system is vulcanizing agent DCP, the lubricating system is oleic acid amide, and the hardening system is Zinc dimethacrylate, the processing aid is alkylphenol formaldehyde resin and fluid dispersant RL-22, the anti-aging system is a mixed system of anti-aging agent NAPM and anti-aging agent RD, in parts by mass, the content of each component is:

[0040]

[0041] A preparation method of a wear-resistant rubber material, the specific steps are as follows:

[0042]Plasticize the raw rubber on the open mill, then heat the glue in the internal mixer to a temperature of 70°C to 90°C (without turning on the cooling water), add super wear-resistant carbon black N220 in 4 times until the mixing is uniform, and the mixing time About 20 minutes; then add alkylphenol formaldehyde resin, m...

Embodiment 3

[0044] A wear-resistant rubber material, the rubber matrix is hydrogenated nitrile rubber with an acrylonitrile content of 25%, the reinforcement system is super wear-resistant carbon black N220, the vulcanization system is vulcanizing agent BIBP, and the lubrication system is ethylene bisoleic acid amide. The hardening system is zinc dimethacrylate, the processing aid is alkylphenol formaldehyde resin and fluidity dispersant RL-22, and the anti-aging system is anti-aging agent NAPM. The contents of each component are as follows in parts by mass:

[0045]

[0046] The specific steps of the preparation method are as follows:

[0047] Plasticize the raw rubber on the open mill, then heat the glue in the internal mixer to a temperature of 70°C to 90°C (without turning on the cooling water), add super wear-resistant carbon black N220 in 4 times until the mixing is uniform, and the mixing time About 20 minutes; then add alkylphenol formaldehyde resin, mix for about 2 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com