High-temperature-resistant ultrapure perfluoroether rubber and preparation method thereof

A technology of perfluoroether rubber and high temperature resistance, which is applied in the field of polymer material preparation, can solve the problems of rubber intolerance to media, less perfluoroether rubber, and small application range, so as to ensure processability, improve high temperature resistance and Excellent mechanical properties and medium resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] According to the protection method requested by this application, the preparation of high temperature resistant ultra-pure perfluoroether rubber is carried out, and the steps are:

[0031] S1. Weigh 100 parts of perfluoroether rubber, 1 part of dispersant, 10 parts of fumed silica, 1.5 parts of accelerator and 1 part of vulcanizing agent.

[0032] S2. Put the rubber, dispersant, fumed silica, vulcanizing agent and accelerator weighed in S1 into the mill at one time and knead at 40-70°C, preferably 60°C, and knead evenly.

[0033] S3. The mixed rubber prepared in S2 is vulcanized for one stage in a vulcanizing machine, and the vulcanization temperature is 170°C.

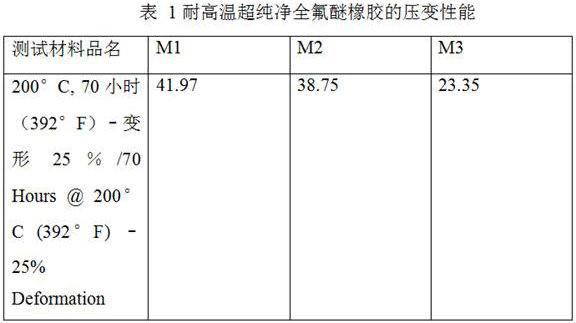

[0034] S4. Put the sealing ring prepared in S3 into an oven for two-stage vulcanization. The vulcanization temperature is set at 200°C, 230°C and 250°C respectively, and the obtained samples are marked as M1, M2, and M3.

[0035] S5. Perform a performance test on the prepared sealing ring, and test the compres...

Embodiment 2

[0038] According to the protection method requested by this application, the preparation of high temperature resistant ultra-pure perfluoroether rubber is carried out, and the steps are:

[0039] S1. Weigh 100 parts of perfluoroether rubber, 1 part of dispersant, 10 parts of fumed silica, 2 parts of accelerator and 1 part of vulcanizing agent according to the dosage of the formula.

[0040] S2. Put the rubber, dispersant, fumed silica, vulcanizing agent and accelerator weighed in S1 into the mill at one time and knead at 40-70°C, preferably 60°C, and knead evenly.

[0041] S3. The mixed rubber prepared in S2 is vulcanized for one stage in a vulcanizer, and the vulcanization temperature is set at 170°C.

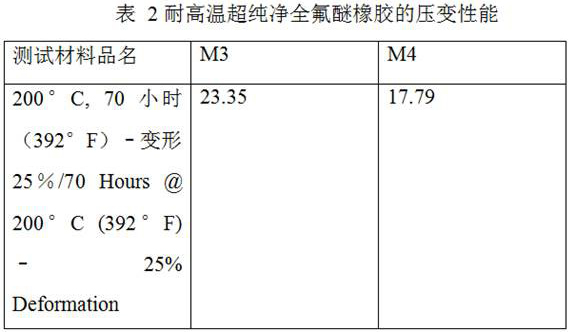

[0042] S4. Put the sealing ring prepared in S3 into an oven for two-stage vulcanization. The vulcanization temperature is set at 250° C., and the obtained sample is designated as M4.

[0043] S5. Perform a performance test on the prepared sealing ring, and test the compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com