Application of resin-based protein composite material in purifying complex-state heavy metals in water

A technology for composite materials and heavy metals, applied in the fields of alkali metal compounds, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems that have not yet been reported in related research, achieve obvious environmental protection benefits, enhance utilization efficiency, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

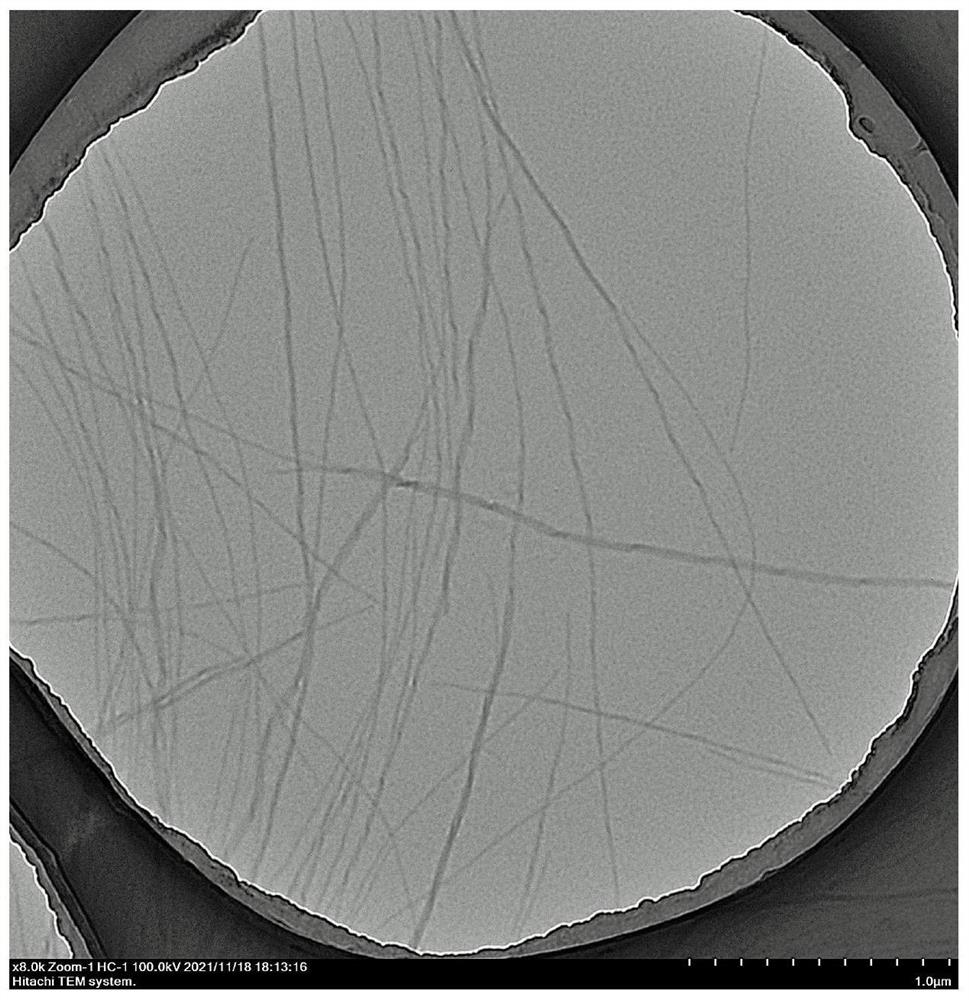

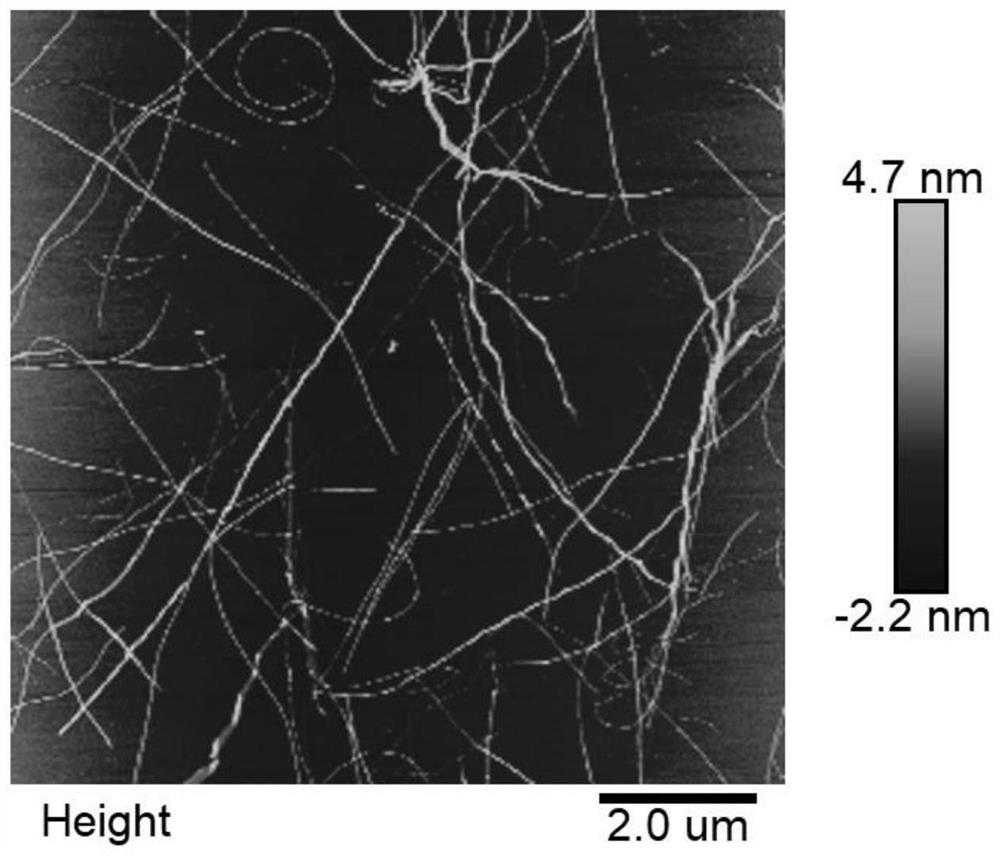

[0026] Accurately weigh 2g of lysozyme protein and dissolve it in 100mL of water, adjust the pH of the solution to 2.0, then place it in a water bath at 85°C and stir for 8 hours to obtain a lysozyme protein with a diameter of about 3-5nm and a length of about 2-15μm Amyloid fibrous material ( Figure 1-2 ); Accurately weigh 5g of D201 ion exchange resin and place in 100mL aqueous solution, mix evenly to obtain resin carrier suspension. Then, take 0.5 mL of lysozyme protein amyloid fibrous material and 0.5 mL of resin carrier suspension and mix well, place in a vacuum filtration device, and obtain amyloid fiber composite membrane (referred to as composite membrane) by suction filtration.

[0027] The amyloid fiber composite membrane prepared above is used as a functional adsorption material, the temperature of the copper citrate sewage is controlled at 5°C, the pH value of the solution is adjusted to 2.0, the concentration of the prepared copper citrate is 1 mg / L, and conventi...

Embodiment 2

[0029] Accurately weigh 5g of lysozyme protein and dissolve it in 100mL of water, adjust the pH of the solution to 4.0, then place it in a 95°C water bath and stir for 10 hours to obtain a lysozyme protein with a diameter of about 3-5nm and a length of about 2-15μm Amyloid fiber material: Accurately weigh 10g of D201 ion exchange resin and place it in 100mL aqueous solution, mix well to obtain a resin carrier suspension. Then, take 0.5 mL of lysozyme protein amyloid fiber material and 1.0 mL of resin carrier suspension and mix well, place in a vacuum filtration device, and obtain amyloid fiber composite membrane (referred to as composite membrane) by suction filtration.

[0030] Use the amyloid fiber composite membrane prepared above as a functional adsorption material, control the temperature of EDTA copper sewage to 25°C, adjust the pH value of the solution to 5.0, prepare the concentration of EDTA copper to 5mg / L, and the conditions under which conventional competitive anion...

Embodiment 3

[0032] Accurately weigh 2g of bovine serum albumin and dissolve it in 100mL of water, adjust the pH of the solution to 3.0, then place it in a water bath at 100°C and stir for 12 hours to obtain bovine serum albumin with a diameter of about 3-5nm and a length of about 2-15μm Amyloid fibrous material: Accurately weigh 15g of D201×7 ion exchange resin, place it in 100mL aqueous solution, and mix evenly to obtain a resin carrier suspension. Then, take 0.5mL of bovine serum albumin amyloid fiber material and 0.5mL of resin carrier suspension and mix well, place in a vacuum filtration device, and obtain amyloid fiber composite membrane (referred to as composite membrane) by suction filtration.

[0033] The amyloid fiber composite membrane prepared above is used as a functional adsorption material, the temperature of the copper oxalate sewage is controlled to 30°C, the pH value of the solution is adjusted to 6.0, the concentration of the prepared copper oxalate is 10 mg / L, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com