Metal structural part and preparation method thereof

A technology of metal structural parts and metal powder, which is applied in the field of metal structural parts and its preparation, can solve the problems of inability to achieve longitudinal solidification depth, hinder metal photocuring forming, and large transverse over-curing width, so as to achieve good longitudinal solidification depth and improve Effects of depth of cure, lift adequacy and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

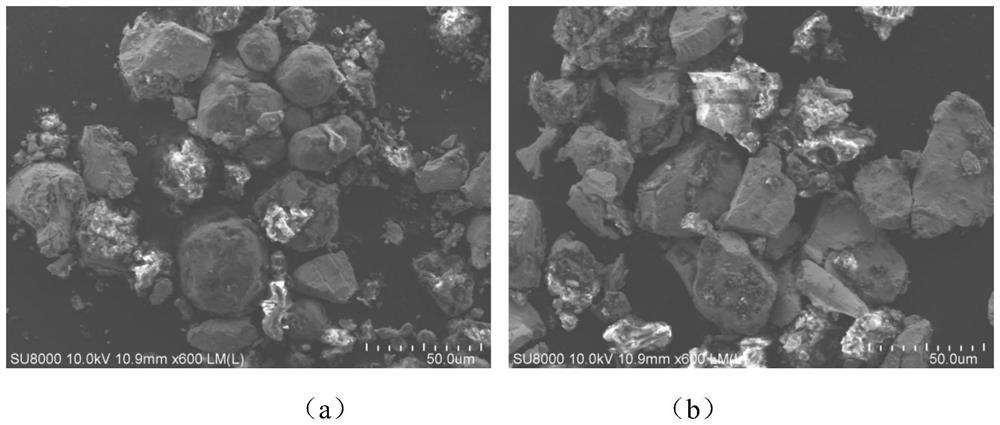

[0052] Step 1, select tantalum metal powder, the particle size range of which is 5-50 μm;

[0053] Step 2, select a filter cloth with a mesh number of 500, cut it and put it into the funnel;

[0054] Step 3, add the metal powder and resin material into the glass funnel in sequence, using a small amount and multiple times, and after it is completely put, let it stand for 2 hours, wherein the modified material is resin, and the total amount of resin material is the total mass of the metal powder 1 / 5;

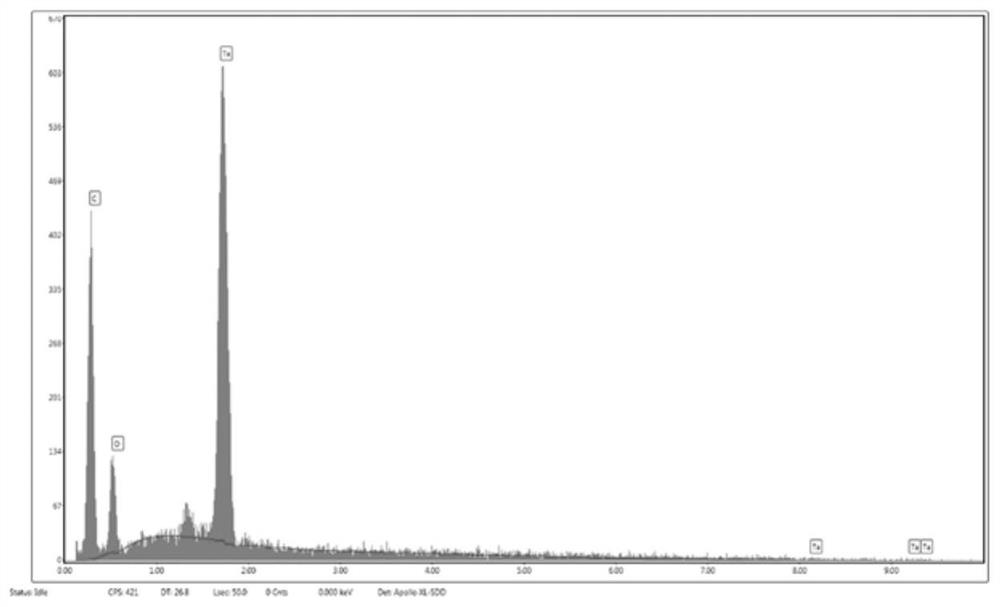

[0055] Step 4, remove the fully infiltrated metal powder from the funnel, press the fully infiltrated powder into a thin sheet on tin foil, with a thickness of about 6mm, put it in a drying oven, and solidify it at 100°C for 4 hours. After fully cooling, carry out Crushing and sieving to obtain modified metal powder wrapped with a resin layer, wherein the thickness of the resin layer is 500 nm, and the particle size range of the metal powder wrapped with the resin layer is 5.5 μm...

Embodiment 2

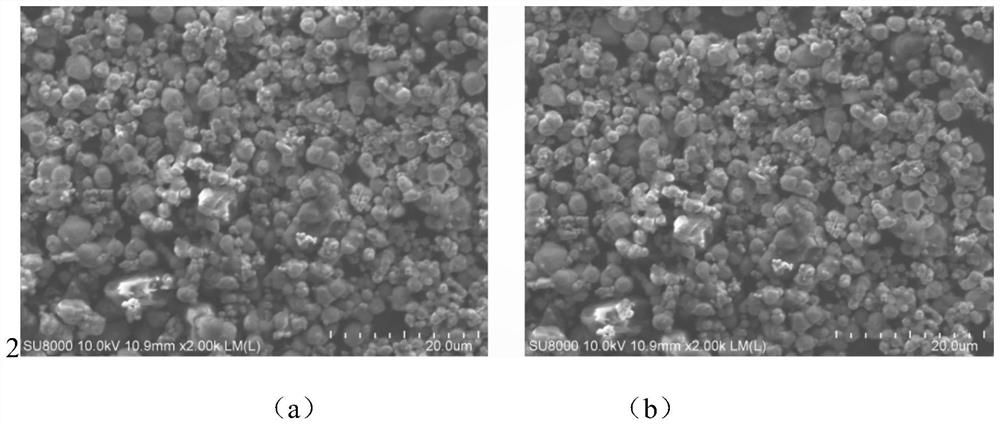

[0060] Step 1, select molybdenum metal powder, the particle size range of which is 200nm-10μm;

[0061] Step 2, select a filter cloth with a mesh number of 1000, cut it and put it into the funnel;

[0062] Step 3, add the metal powder and resin material into the glass funnel in sequence, using a small amount and multiple times, and after it is completely put, let it stand for 3 hours, wherein the modified material is resin, and the total amount of resin material is the total mass of the metal powder 1 / 3;

[0063] Step 4, remove the fully infiltrated metal powder from the funnel, press the fully infiltrated powder on tin foil to form a thin sheet with a thickness of about 7mm, put it in a drying oven, and solidify at 120°C for 3 hours. After fully cooling, carry out Crushing and sieving to obtain modified metal powder wrapped with a resin layer, wherein the thickness of the resin layer is 1 μm, and the particle size range of the metal powder wrapped with the resin layer is 1.2...

Embodiment 3

[0068] Step 1, selecting titanium metal powder, the particle size range of which is 5-50 μm;

[0069] Step 2, select a filter cloth with a mesh number of 1000, cut it and put it into the funnel;

[0070] Step 3, add the metal powder and resin material into the glass funnel in sequence, using a small amount and multiple times, after completely putting it away, let it stand for 1.5 hours, wherein the modified material is resin, and the total amount of resin material used is the total mass of the metal powder 1 / 10 of;

[0071] Step 4, remove the fully infiltrated metal powder from the funnel, press the fully infiltrated powder into a thin sheet on tin foil, with a thickness of about 6mm, put it in a drying oven, and solidify it at 115°C for 3 hours. After fully cooling, carry out Crushing and sieving to obtain the modified metal powder wrapped with a resin layer, wherein the thickness of the resin layer is 300nm, and the particle size range of the metal powder wrapped with the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com