Method for preparing perovskite oxide nano material by using microwave method

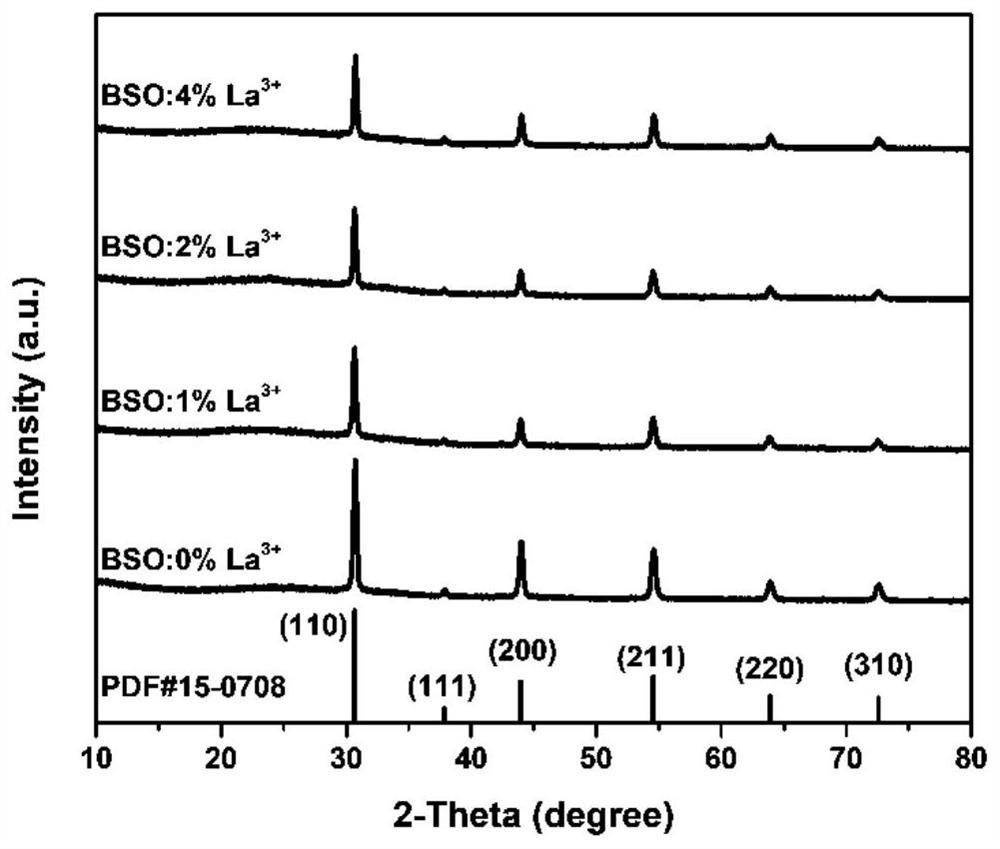

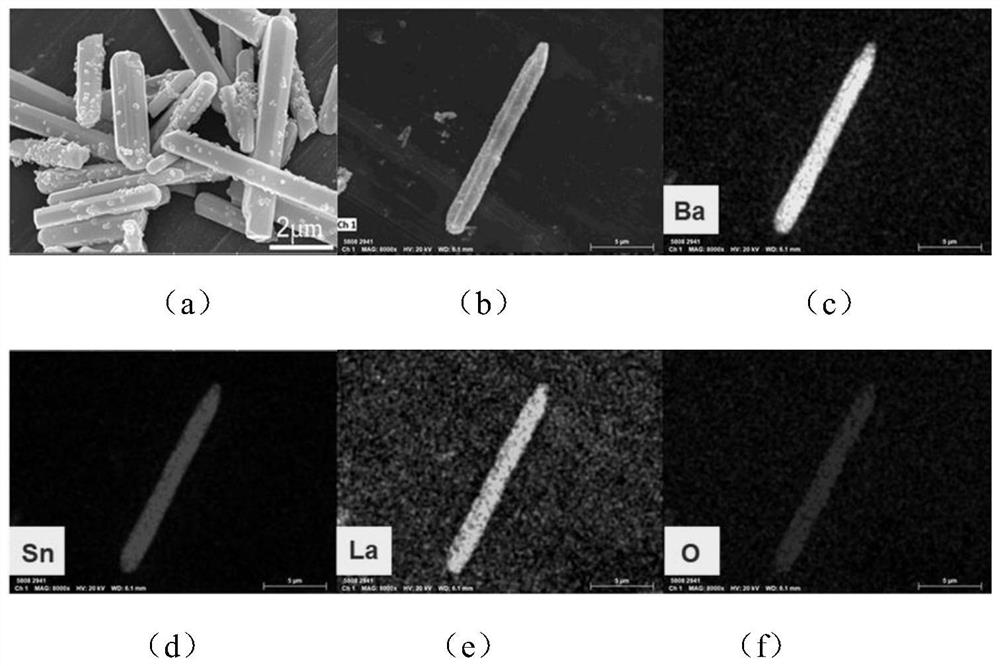

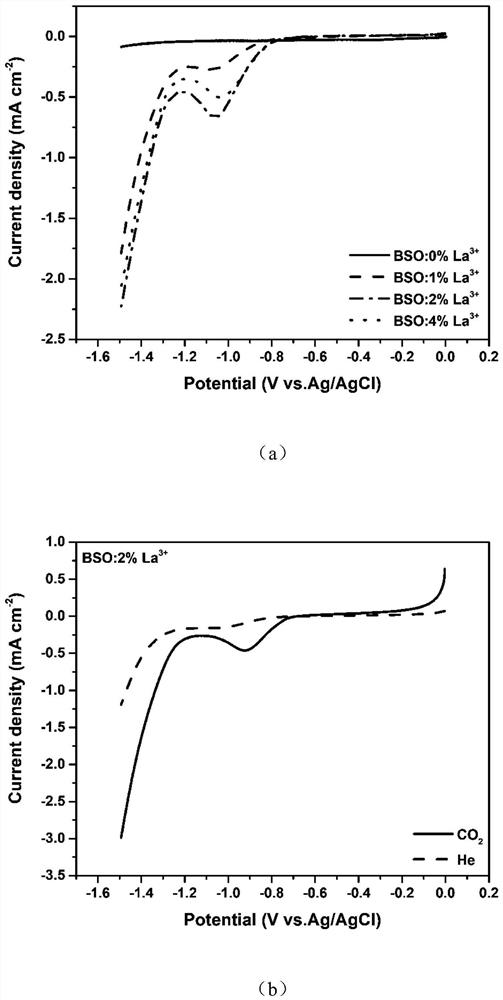

A technology of perovskite oxides and nanomaterials, applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., can solve the problems of high sintering temperature, large grain size, particle agglomeration, etc., and achieve good crystallinity and thermal energy. The effect of high utilization and high phase purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing perovskite oxides for carbon dioxide reduction catalytic reaction by microwave method, comprising the following steps:

[0036] (1) Add 9mL of deionized water into the beaker, start to stir, add 1mmol of barium nitrate (x=0.01), 0mmol of lanthanum nitrate, and 1mmol of tin chloride pentahydrate in sequence, and stir for 10min until completely dissolve;

[0037] (2) Prepare 2mol / L sodium hydroxide solution, add 12mL of the prepared sodium hydroxide solution dropwise to the solution in step (1), and continue stirring for 30min;

[0038] (3) Transfer the solution obtained in step (2) to a microwave reaction tube, adjust the infrared reaction temperature to 170° C., and the reaction time to 60 minutes;

[0039] (4) Wash the precipitate obtained in step (3) with water for 4 to 5 times in a high-speed centrifuge until neutral, and adjust the centrifuge speed to 9800r / min for 3 minutes.

[0040] (5) Place the water-washed precipitate obtained in step (...

Embodiment 2

[0046] The difference from the embodiment is that x=0.01, and other processes are the same as the embodiment 1.

Embodiment 3

[0048] The difference from the embodiment is that x=0.02, and other processes are the same as the embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com