Anti-sticking agent for stainless steel surface coating of polyreactor and preparation method of anti-sticking agent

A polymerization reaction kettle and surface coating technology, which is applied in coatings, hyaluronic acid coatings, chitin polysaccharide coatings, etc., can solve the problem of ineffective prevention of polymer and stainless steel surface bonding, short cleaning period of polymerization kettles, Poor performance of anti-sticking agent and other problems, to achieve excellent anti-sticking effect, improve the cycle of cleaning the kettle, and improve the appearance of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of anti-sticking still agent of stainless steel surface coating of polymerization reaction kettle, it is characterized in that, comprises the following steps:

[0031] S1, add deionized water to the synthesis kettle to provide better acid-base balance reaction conditions for the product, reduce the impact of other pollutants, start stirring and heating to improve the uniformity of heating, heat the deionized water, and synthesize The kettle is heated to 90-95°C to improve the dissolution efficiency and reaction efficiency;

[0032] S2, adding aqueous sodium hydroxide solution to the synthesis kettle through the liquid caustic head tank to increase the pH value of the reaction solution;

[0033] S3, add mixed phenol and sodium bisulfite to the solid feeding port of the synthesis kettle, the polymerization inhibition efficiency of the main active ingredients of the anti-sticking kettle agent can be greatly improved by mixing phenol, and sodium...

specific Embodiment approach 1

[0039]Add 910 kilograms of deionized water into the synthesis kettle, start stirring and start to heat up, add 98 kilograms of sodium hydroxide aqueous solution through the liquid alkali head tank, add 100 kilograms of a-naphthol and p-tert-butylcatechol, m- The mixture of hydroquinone and 25 kg of sodium bisulfite, start airtight heating, control the reaction temperature at 90-95 ° C, after the material is completely dissolved, start to add 200 kg of formaldehyde through the formaldehyde high level tank, keep the temperature for 1 hour after adding formaldehyde, Allow the reaction to fully complete. Add 300 kg of ethanol and 10 kg of chitin, 25 kg of polyvinyl alcohol and continue to keep warm for about 2 hours to completely dissolve the material.

specific Embodiment approach 2

[0040] Add 880 kilograms of deionized water into the synthesis kettle, start stirring and start to heat up, add 98 kilograms of sodium hydroxide aqueous solution through the liquid alkali head tank, add 100 kilograms of a-naphthol and p-tert-butylcatechol, m- The mixture of hydroquinone and 25 kg of sodium bisulfite, start airtight heating, control the reaction temperature at 90-95 ° C, after the material is completely dissolved, start to add 200 kg of formaldehyde through the formaldehyde high level tank, keep the temperature for 1 hour after adding formaldehyde, Allow the reaction to fully complete. Add 300 kg of ethanol and 10 kg of chitin, 25 kg of polyvinyl alcohol and continue to keep warm for about 2 hours to completely dissolve the material.

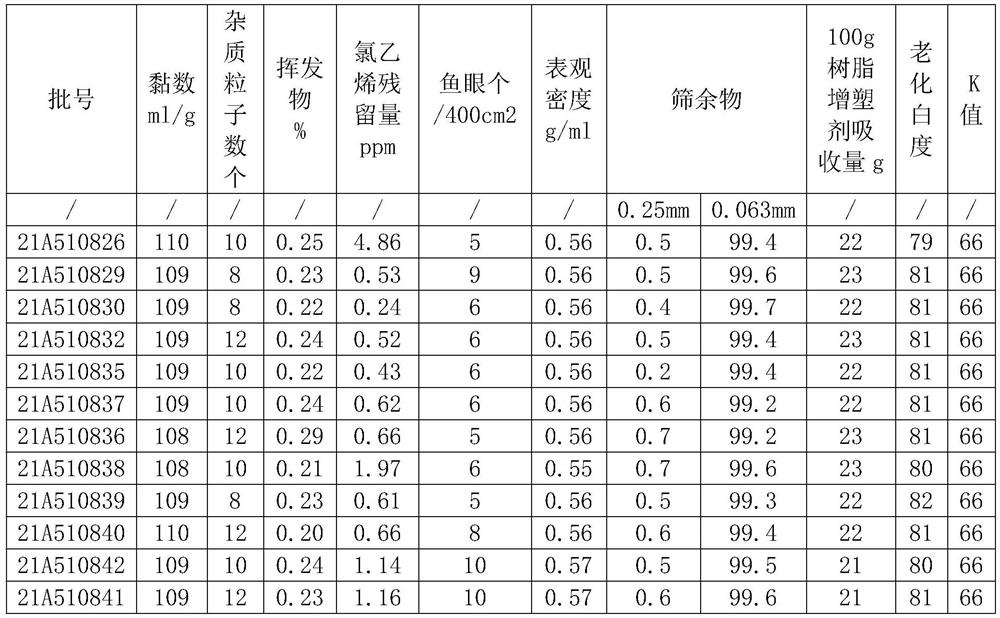

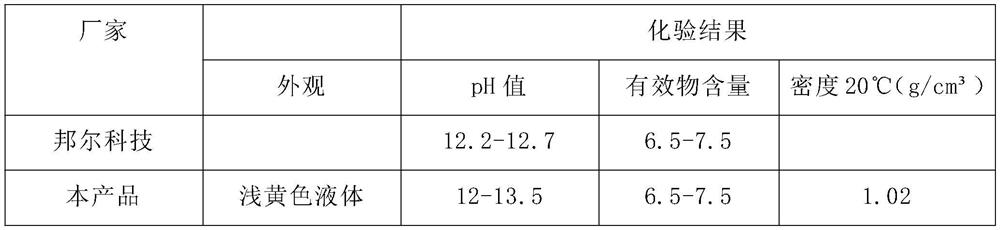

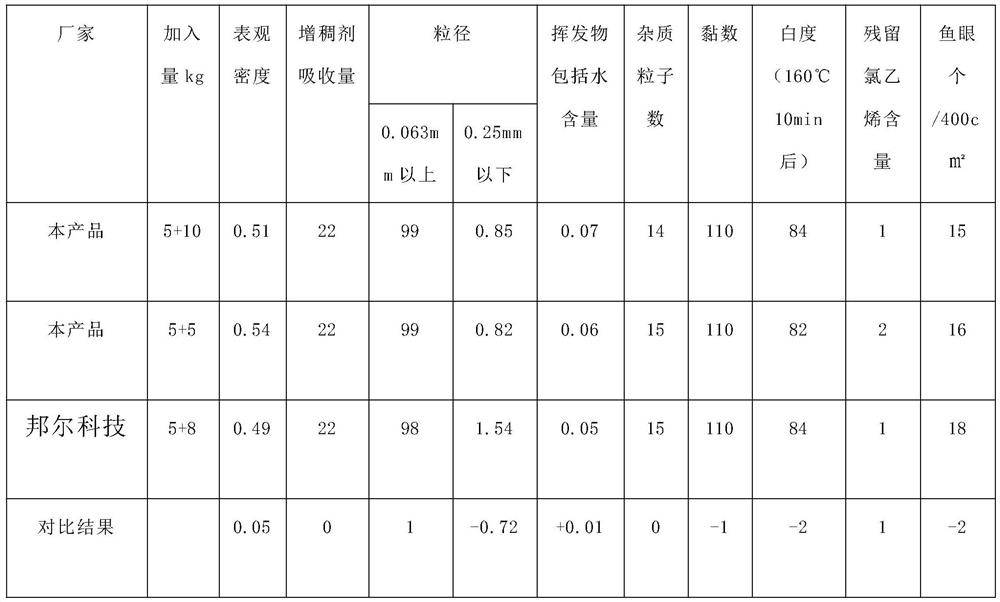

[0041] Analysis index of finished product of the present invention:

[0042] Appearance: light yellow transparent liquid;

[0043] Solid content: (10±0.5)%; PH value: 12-14;

[0044] Density: 1.00-1.03(g / ml);

[0045] This pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com