Chrome-free tanning process for ecological leather

A chrome-free tanning and ecological technology, applied in the field of leather processing, can solve the problems of the limitation of the promotion and application of chrome-free tanning technology, increasing the organic pollution load of dyeing and finishing wastewater, and the insufficient bonding rate of dyeing and finishing materials, and achieves improved distribution uniformity and positive electricity. The effect of strong sex and high isoelectric point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

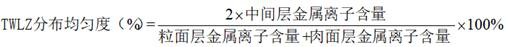

[0043] Put the pickled cowhide obtained according to the conventional process in a drum, add 60 wt% of pickling solution based on the weight of limed bare hide and 5 wt% of chrome-free organic tanning agent TWS, rotate for 3 h, and use sodium carbonate After raising the alkali with sodium bicarbonate to pH 7.7, add 150 wt% hot water based on the weight of liming bare hide, keep the temperature of the bath liquid at 42°C, rotate for 2 hours, stop the drum overnight, and turn for 0.5h the next day Finally, drain the liquid; add 30 wt% normal temperature water and 2.5 wt% sodium lignosulfonate based on the weight of liming bare hide into the drum, rotate for 1.2 h, adjust the pH of the bath solution to 3.8 with formic acid, and then add chrome-free metal tanning agent TWLZ with 4 wt% by weight of liming bare hide, continue to rotate for 4 h, use automatic alkali raising agent MGO to elevate alkali to pH 4.0, add 200 wt% hot water by weight of liming bare hide, Keep the temperatur...

Embodiment 2

[0072] Put the pickled goatskin obtained by the conventional process in a drum, add 100 wt% of pickling solution based on the weight of limed bare hide and 3 wt% of chrome-free organic tanning agent TWS, rotate for 4 h, and use carbonic acid Sodium and sodium bicarbonate to improve the alkali to pH 8.5, add 200 wt% hot water based on the weight of liming bare hide, keep the temperature of the bath at 35°C, rotate for 1 hour, stop the drum overnight, and turn 0.5% the next day After 2 hours, drain the liquid; add 60 wt% of normal temperature water and 1 wt% sodium lignosulfonate based on the weight of liming bare hide to the drum, rotate for 2 h, adjust the pH of the bath solution to 4.5 with formic acid, and then add 6 wt% chrome-free metal tanning agent TWLZ based on the weight of limed bare hide, continue to rotate for 1 h, use sodium bicarbonate to elevate the alkali to pH 4.5, add 100 wt% hot water based on the weight of limed bare hide, and make The temperature of the bat...

Embodiment 3

[0075]Place the pickled sheepskin obtained by the conventional process in a drum, add 30 wt% of pickling solution and 1 wt% of chrome-free organic tanning agent TWS based on the weight of limed bare hide, rotate for 2 h, and use carbonic acid Sodium and sodium bicarbonate to improve the alkali to pH 7.0, then add hot water of 100 wt% based on the weight of liming bare skins, keep the temperature of the bath at 38°C, rotate for 3 hours, stop the drum overnight, and turn to 0.5% the next day. After one hour, drain the liquid; add 100 wt% normal temperature water and 4 wt% sodium lignosulfonate based on the weight of liming bare hide to the drum, rotate for 0.5 h, adjust the pH of the bath solution to 3.0 with formic acid, and then add 2 wt% chrome-free metal tanning agent TWLZ based on the weight of liming bare hide, continue to rotate for 2.5 h, use sodium carbonate to elevate the alkali to pH 3.5, add 150 wt% hot water based on the weight of liming bare hide, and make the bath ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com