A kind of formaldehyde removal agent and preparation method thereof

A technology of aldehyde remover and filler, applied in the field of leather manufacturing, to achieve the effect of simple use, bright color and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

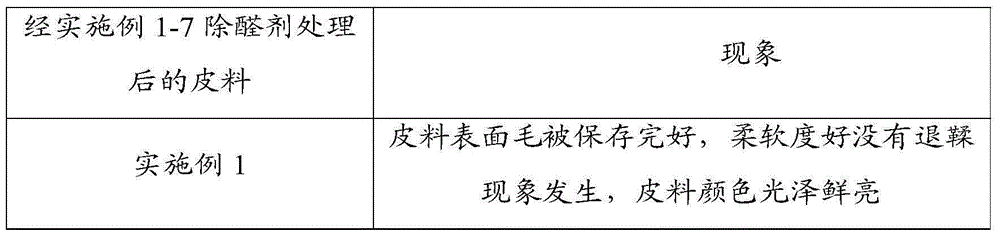

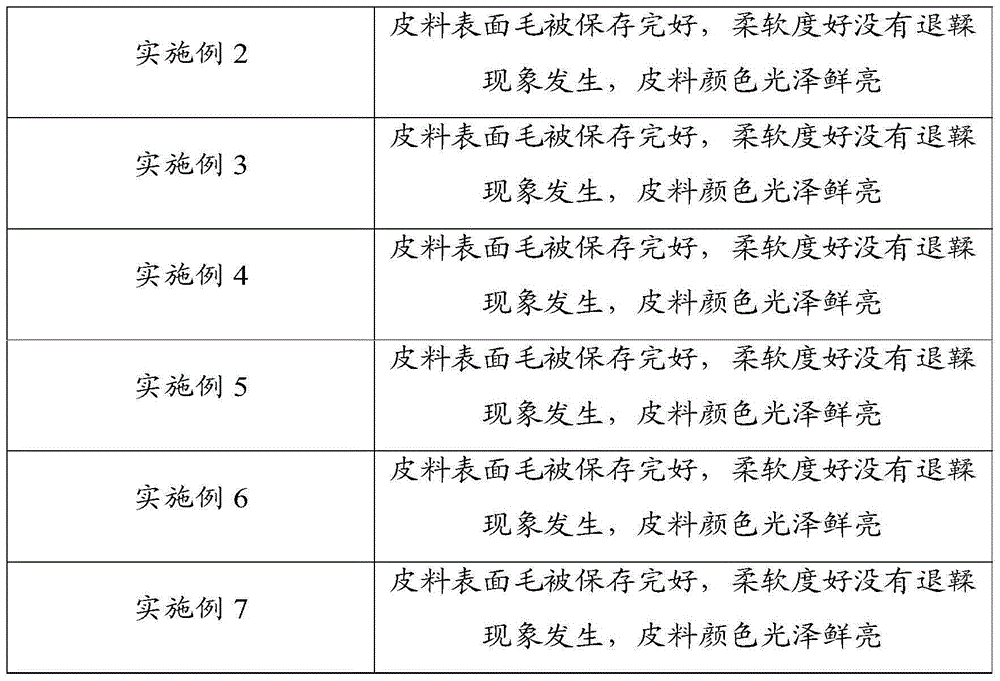

Examples

Embodiment 1

[0022] The preparation method of aldehyde removal agent is as follows:

[0023] (A) The following raw materials are all weighed for later use: 10kg of urea, 40kg of collagen, 10kg of sodium dodecylbenzenesulfonate, 10kg of sodium carbonate, 2kg of diatom mud, and 30kg of sodium sulfite;

[0024] (B) Mix and stir the above-mentioned raw materials weighed well to get the aldehyde remover.

Embodiment 2

[0026] The preparation method of aldehyde removal agent is as follows:

[0027] (A) Weigh the following raw materials for later use: ethylene urea 100kg, protein powder 20kg, sodium lauryl sulfate 20kg, sodium bicarbonate 20kg, white clay 5kg, vitamin C 50kg;

[0028] (B) Grinding the above-mentioned raw materials with weighed quality evenly to obtain the aldehyde remover.

Embodiment 3

[0030] The preparation method of aldehyde removal agent is as follows:

[0031] (A) The following raw materials are all weighed for subsequent use: 50kg of the mixture of guanidine hydrochloride and amino acid, 10kg of the mixture of protein powder and aluminum sulfate, AEO-91kg, 1kg of potassium carbonate, 1kg of kaolin, 10kg of the mixture of vitamin C and thiourea dioxide;

[0032] (B) Grind the above-mentioned raw materials weighed well until the particle size is 400-500 mesh to obtain the aldehyde remover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com