Anti-icing super-hydrophobic coating constructed on surface of metal copper in situ, preparation method and application of anti-icing super-hydrophobic coating

A super-hydrophobic coating and anti-icing technology, which can be applied to devices, coatings, anti-corrosion coatings, etc. for coating liquids on the surface, can solve the problems of high cost, complex preparation process of anti-icing super-hydrophobic surface, etc. Low, excellent hydrophobicity, roughness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1, the preparation of CuO surface on metal copper surface

[0035] Add 300mL deionized water into the beaker, add 40g sodium hydroxide, add deionized water to the solution 500mL mark after dissolving, and obtain sodium hydroxide solution; use 2.5g sodium hydroxide, 3.5g sodium phosphate, 3.5g sodium carbonate Dissolve 2.5g of sodium silicate in 100mL of ionized water to prepare degreasing solution; use 125ml / L hydrochloric acid to prepare pickling solution.

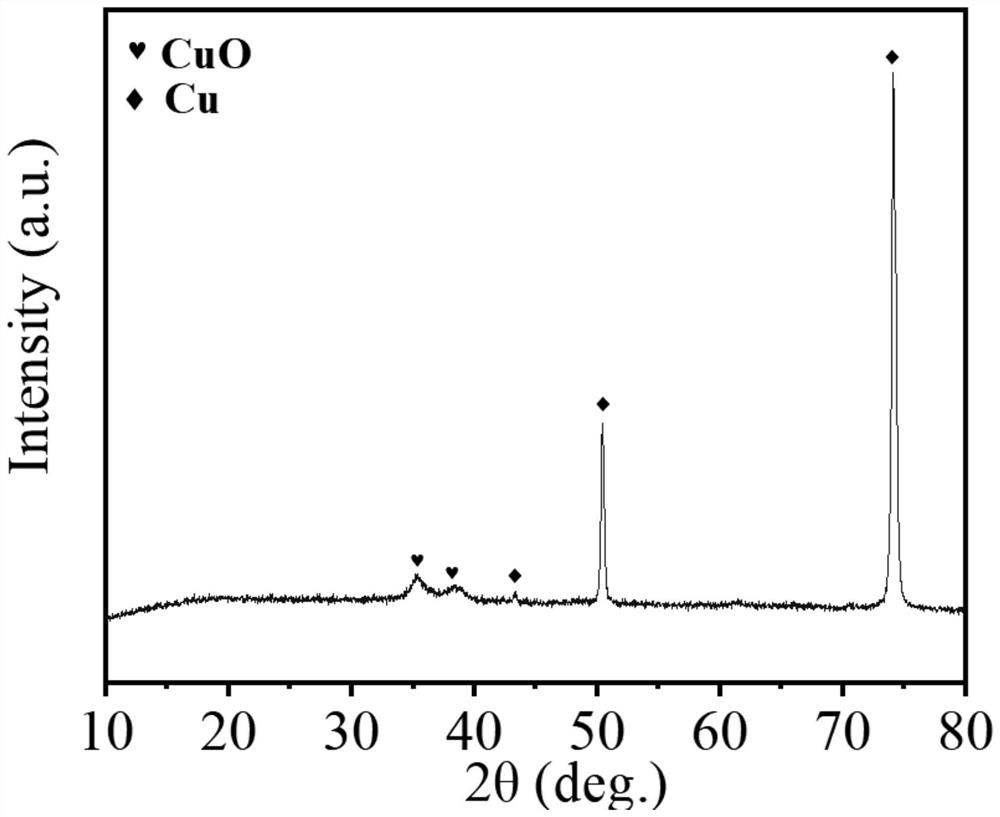

[0036] Then, the copper sheet of the anode is subjected to pretreatment such as degreasing, pickling and ultrasonic ethanol cleaning in order to remove grease and impurities on the metal surface; at a temperature of 20°C, the current is kept at 2mA / cm 2 Oxidation for 15min to obtain Cu(OH) 2 surface, the anodized Cu(OH) 2 The surface was placed in an oven at 180°C for 2 hours to obtain a CuO surface.

[0037] Step 2. Preparation of universal superhydrophobic coating for anti-icing on copper-based surface

...

Embodiment 2

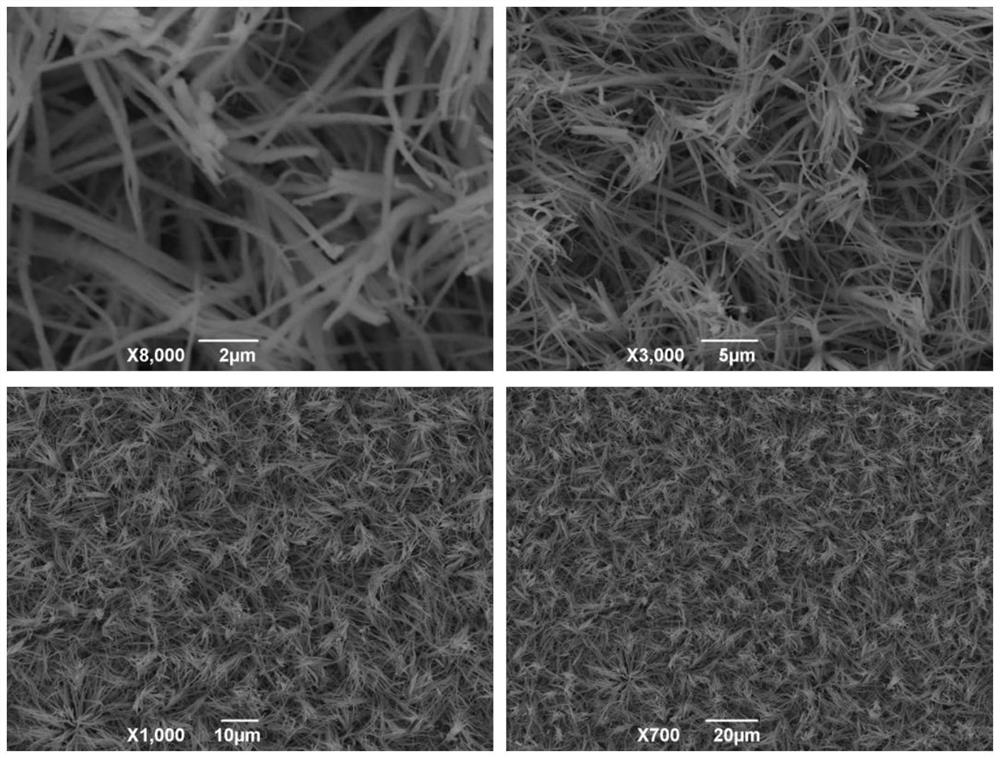

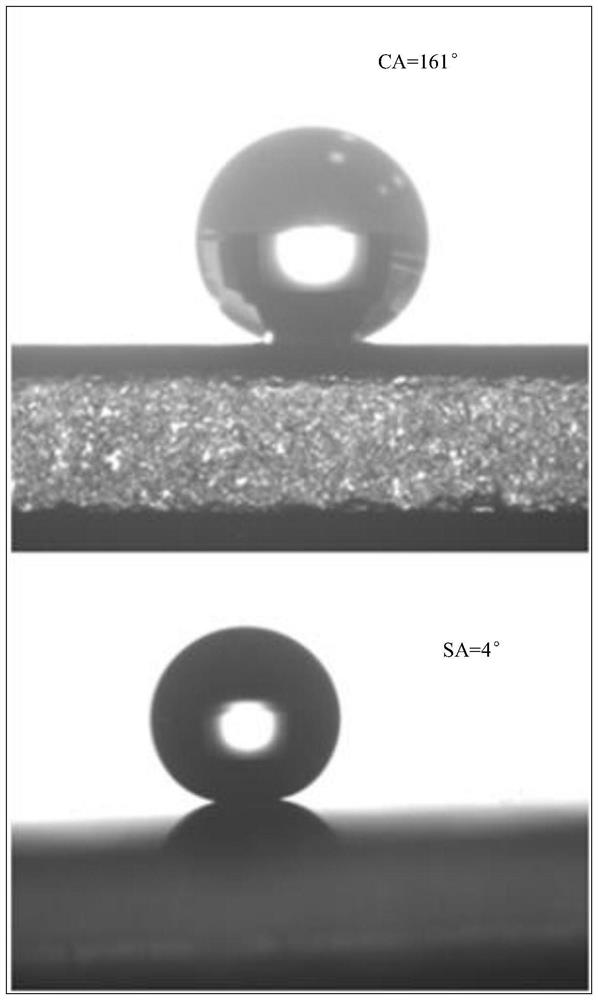

[0046] Change the concentration of sodium hydroxide solution in Step 1 of Example 1 to 1mol / L, change the temperature to 15°C, change the anodic oxidation time to 5min, and change the current density to 2mA / cm 2, all the other processes are shown in Example 1, its surface scanning image and static water contact angle are as follows Figure 7 (a) shown. The static water contact angle on the surface of the sample can reach 161°, and the surface presents a nano-needle-like multi-level micro-nano structure morphology.

Embodiment 3

[0048] Change the concentration of sodium hydroxide solution in Step 1 of Example 1 to 3mol / L, change the temperature to 25°C, change the anodic oxidation time to 10min, and change the current density to 5mA / cm 2 , all the other processes are shown in Example 1, its surface scanning image and static water contact angle are as follows Figure 7 (b) shown. The static water contact angle on the surface of the sample can reach 161°, and the surface presents a pine needle-like multi-level micro-nano structure morphology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com