Positive electrode composite material, preparation method thereof and lithium ion battery

A composite material and positive electrode technology, which is applied in the field of positive electrode composite materials and its preparation, can solve the problems of reducing the structural stability of LMFP, reducing battery cycle performance, and intensifying the dissolution of manganese element, so as to improve structural stability, high structural stability, The effect of good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Correspondingly, the present application also provides a method for preparing a positive electrode composite material to prepare the above positive electrode composite material. Wherein, the preparation method comprises:

[0037] S01, dispersing the lithium manganese iron phosphate material, the high-nickel ternary material and the first conductive agent in a solvent to obtain a mixed material;

[0038] S02, performing fusion treatment on the mixed material in a mechanical fusion machine, and then drying treatment to obtain the positive electrode composite material.

[0039] Optionally, in step S01, the solvent can be N-methylpyrrolidone (NMP), dimethylformamide (DMF), dimethyl sulfoxide (DMSO), acetone, absolute ethanol, isopropanol, etc. One or more, but not limited to.

[0040] Optionally, in step S02, the rotational speed of the mechanical fusion machine is 4000-7000r / min, preferably 4500-6500r / min.

[0041] Optionally, the time for the fusion treatment is 10-30 ...

Embodiment 1

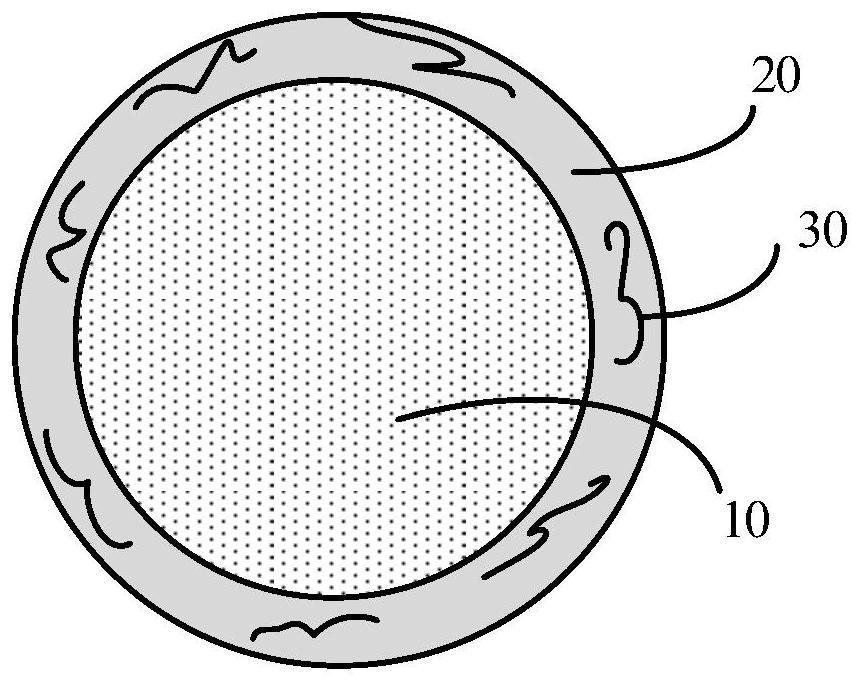

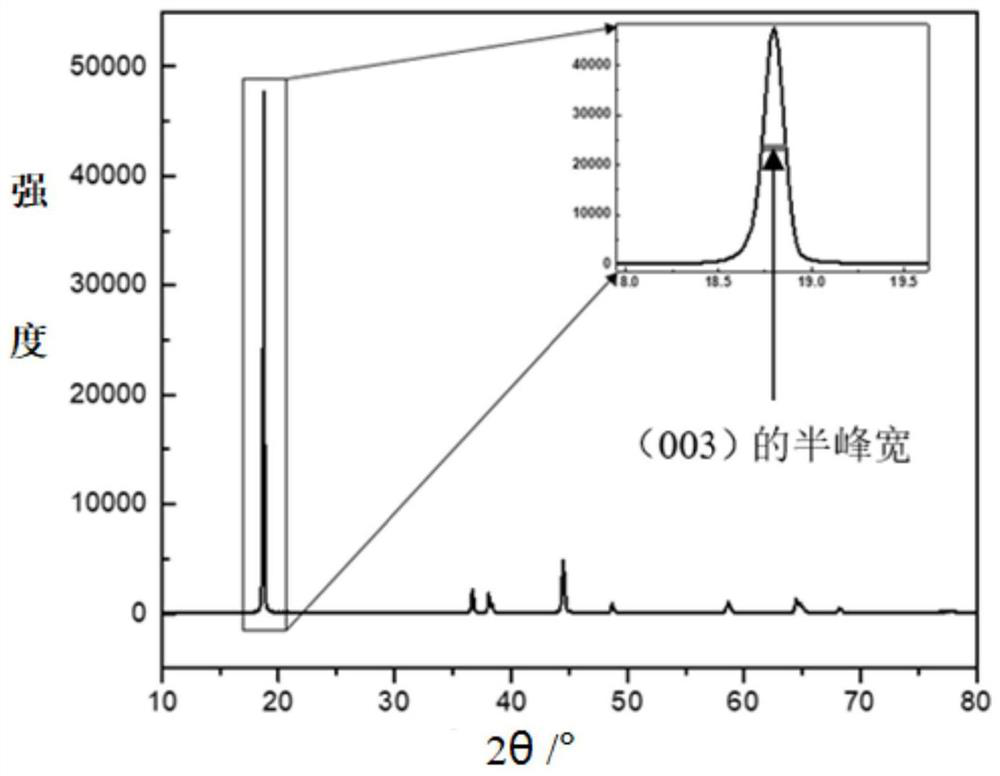

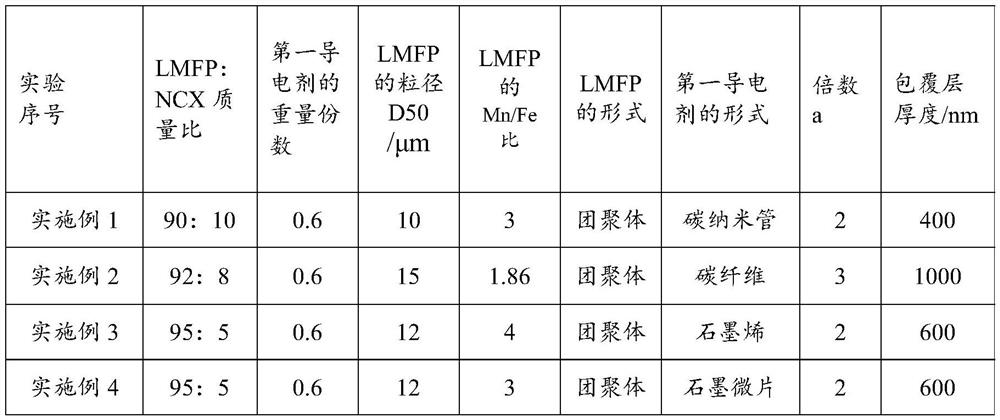

[0063] A kind of positive electrode composite material, comprises LMFP material and the covering layer that is coated on the surface of LMFP material, and wherein, covering layer comprises ternary material NCX, the half peak of (003) crystal plane diffraction peak in the XRD pattern of this ternary material Width≤0.09°; the cladding layer is also doped with a first conductive agent. Wherein, the parts by weight of LMFP, NCX and the first conductive agent are as shown in Table 1, the L of the first conductive agent 1 It is a times the D50 particle size of the LMFP material, and the value of a is shown in Table 1.

[0064] According to the parameters provided in Table 1, positive electrode composite materials of other embodiments were provided respectively.

[0065] Preparation of positive electrode sheet: Add a certain proportion of organic solvent NMP and binder PVDF into the mixer, stir for 1 hour, and then add conductive agent (specifically carbon tube, carbon black, carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap