Preparation method of wide-temperature-range honeycomb type SCR (Selective Catalytic Reduction) denitration catalyst

A denitration catalyst, honeycomb technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

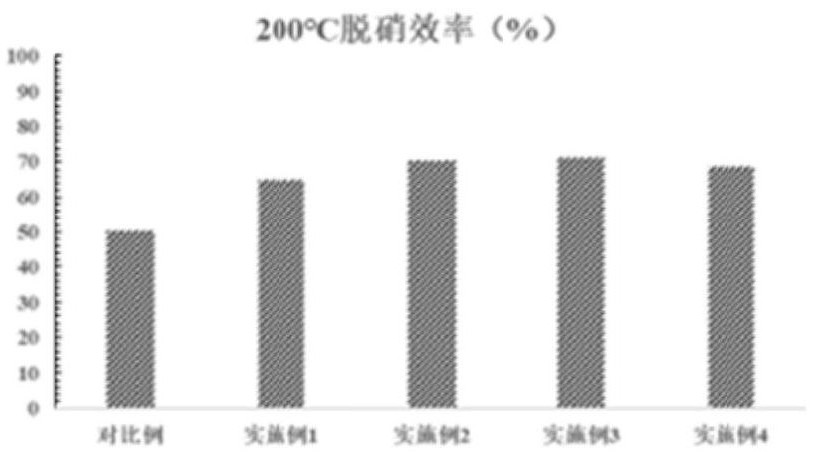

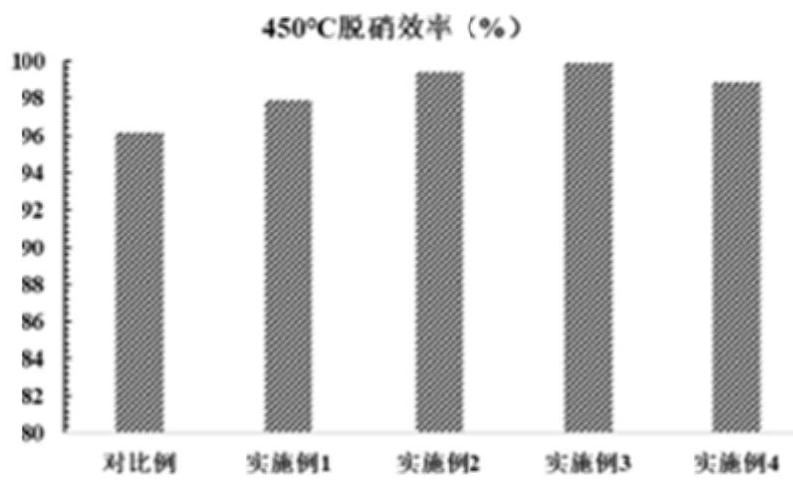

Examples

Embodiment 1

[0027] Step 1. Honeycomb metal substrate pretreatment

[0028] Soak the Fe-Cr-C honeycomb metal substrate in 5% dilute hydrochloric acid solution for 1.5h, and then bake it at 500°C for 1h;

[0029] Step 2. Carrier Layer Coating

[0030] Weigh 826.5g nanometer TiO 2 and 174g of nano-aluminum sol with a solid content of 25%, after mixing evenly, add 82.6g of hydroxyethyl cellulose and 82.6g of polyethylene oxide, use a high-speed mixer to mix for 0.5h, and adjust the kinematic viscosity to 200mm with water during stirring 2 / s; Weigh the pretreated honeycomb matrix and immerse it in the viscous liquid of the carrier layer to stay for 30s, take out the honeycomb upside down and use 2000MHz microwave to quickly dry for 90s, weigh the mass after drying and increase the weight by 262g, and complete the carrier layer coating ;

[0031] Step 3. Active layer coating

[0032] Dissolve 25.7g of ammonium metavanadate with a solution containing 15.4g of monoethanolamine at 90°C, then ...

Embodiment 2

[0037] Step 1. Honeycomb metal substrate pretreatment

[0038] Soak the Fe-Cr-C honeycomb metal substrate in 2% dilute hydrochloric acid solution for 3h, and then bake it at 500°C for 3h;

[0039] Step 2. Carrier Layer Coating

[0040] Weigh 663g nanometer TiO 2 and 468g of nano-aluminum sol with a solid content of 25%, after mixing evenly, add 66.3g of hydroxyethyl cellulose and 66.3g of polyethylene oxide, and use a high-speed mixer to mix for 0.5h. During the stirring process, water is used to adjust the kinematic viscosity to 150mm 2 / s; After weighing the pretreated honeycomb matrix, it is immersed in the viscous liquid of the carrier layer as a whole and stays for 15s. After taking out the honeycomb upside down, use 2500MHz microwave to quickly dry for 45s. After drying, the weighing weight increases by 231g, and the carrier layer coating is completed;

[0041] Step 3. Active layer coating

[0042] Dissolve 51.4g of ammonium metavanadate with a solution containing 30....

Embodiment 3

[0047] Step 1. Honeycomb metal substrate pretreatment

[0048] Soak the Fe-Cr-C honeycomb metal substrate in 2.5% dilute hydrochloric acid solution for 2h, and then bake it at 500°C for 2h;

[0049] Step 2. Carrier Layer Coating

[0050] Weigh 720g nanometer TiO 2 and 320g of nano-aluminum sol with a solid content of 25%, after mixing evenly, add 43.2g of hydroxyethyl cellulose and 57.6g of polyethylene oxide, and use a high-speed mixer to mix for 0.5h. During the stirring process, water is used to adjust the kinematic viscosity to 160mm 2 / s; After weighing the pretreated honeycomb substrate, the whole body is immersed in the viscous liquid of the carrier layer and stays for 20s. After taking out the honeycomb and turning it upside down, use 2200MHz microwave to quickly dry for 60s.

[0051] Step 3. Active layer coating

[0052] Dissolve 38.6g of ammonium metavanadate with a solution containing 23.2g of monoethanolamine at 90°C, then add 171.5g of ammonium heptamolybdate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com