Garbage transfer station leachate treatment integrated device and method

A waste transfer station and leachate technology, applied in the field of leachate treatment, can solve the problems of unstable nitrogen removal effect, substandard total nitrogen and ammonia nitrogen, and large installation area, and save aeration energy consumption and organic load. Tall, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

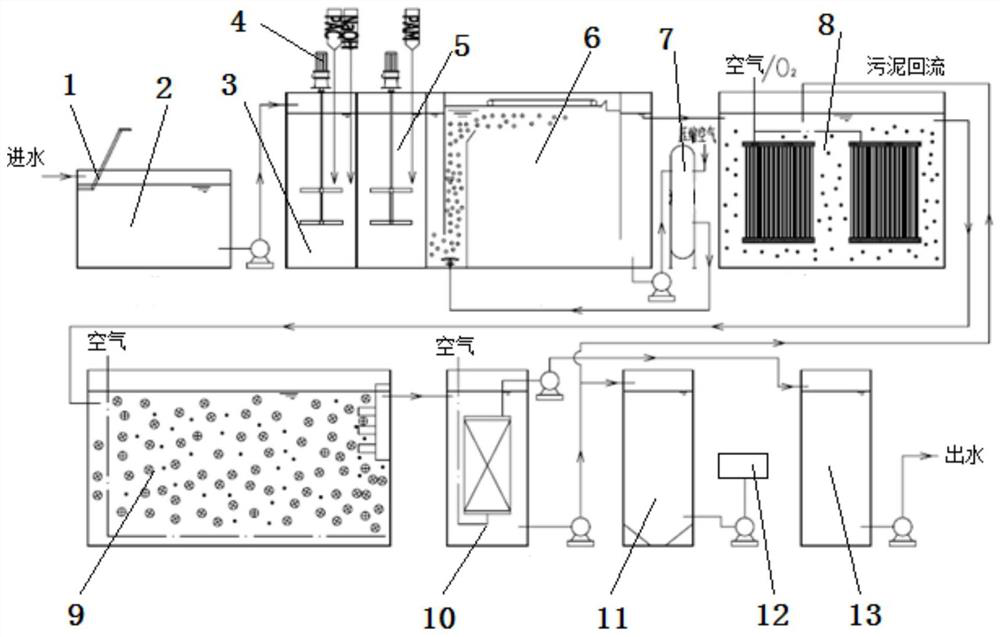

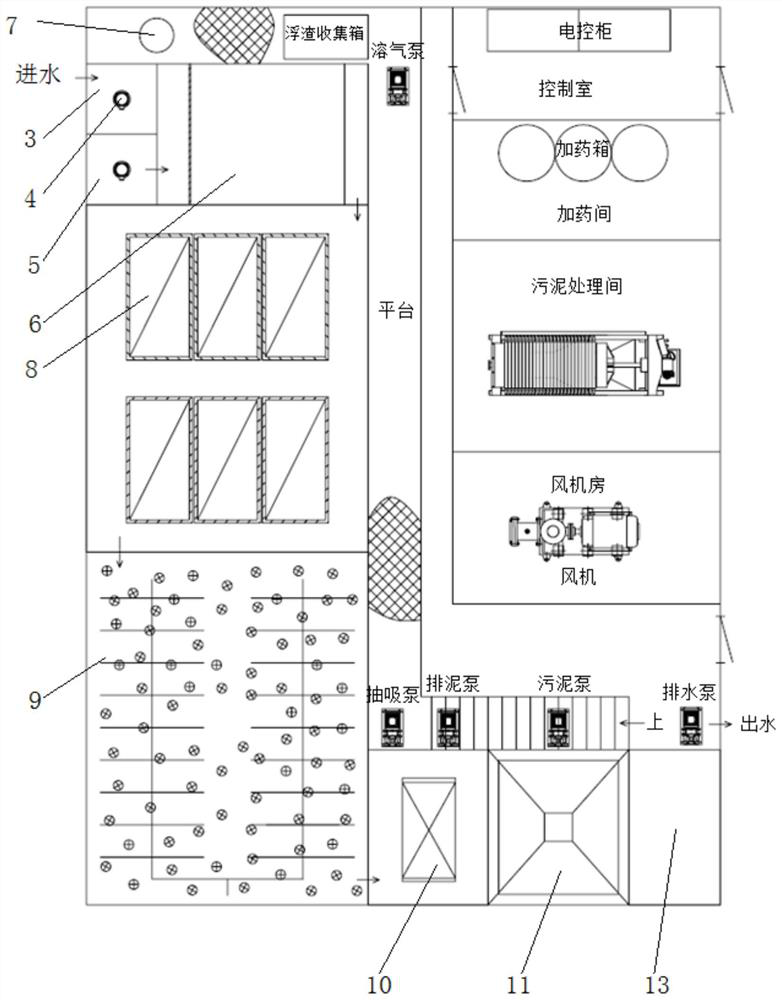

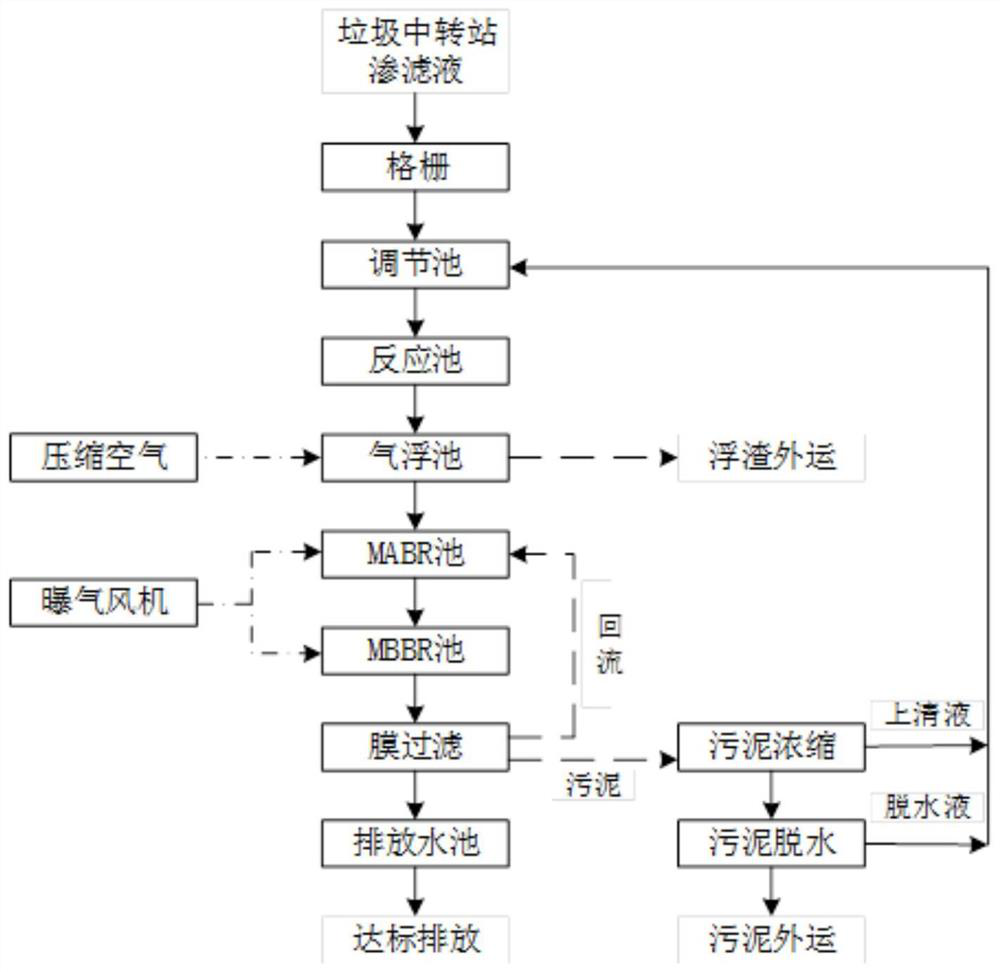

[0032] like Figure 1-2 As shown, a leachate treatment integrated device of a garbage transfer station described in this embodiment includes a pretreatment unit, a biochemical treatment unit and a sludge treatment unit. The pretreatment unit includes a regulating tank 2, a reaction tank and an air flotation tank 6. The outlet of regulating tank 2 is connected to the inlet of reaction tank, the outlet of reaction tank is connected to the inlet of air flotation tank 6; the biochemical treatment unit includes MABR tank 8, MBBR tank 9 and MBR tank 10, the outlet of air flotation tank 6 is connected to the inlet of MABR tank 8, and the outlet of MABR tank 8 is connected to MBBR Pool 9 entrance, MBBR pool 9 outlet is connected to MBR pool 10, the first outlet of MBR pool 10 is connected to MABR pool 8 entrance; the sludge treatment unit includes sludge thickening pool 11 and sludge dehydrator 12, the first outlet of MBR pool 10 It is connected to the inlet of the sludge thickening t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com