Method for synthesizing rosuvastatin calcium intermediate by using continuous flow microchannel reactor

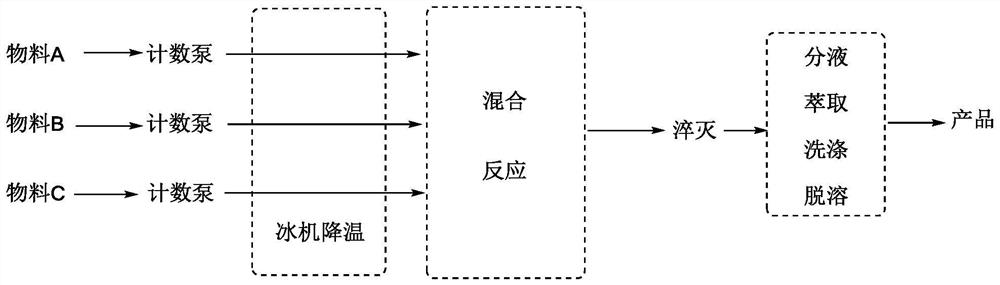

A technology of rosuvastatin calcium and channel reactor is applied in the field of synthesis of rosuvastatin calcium intermediates, which can solve the problems of low product yield and complicated post-processing process, and achieve simple post-processing and short reaction time. , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]

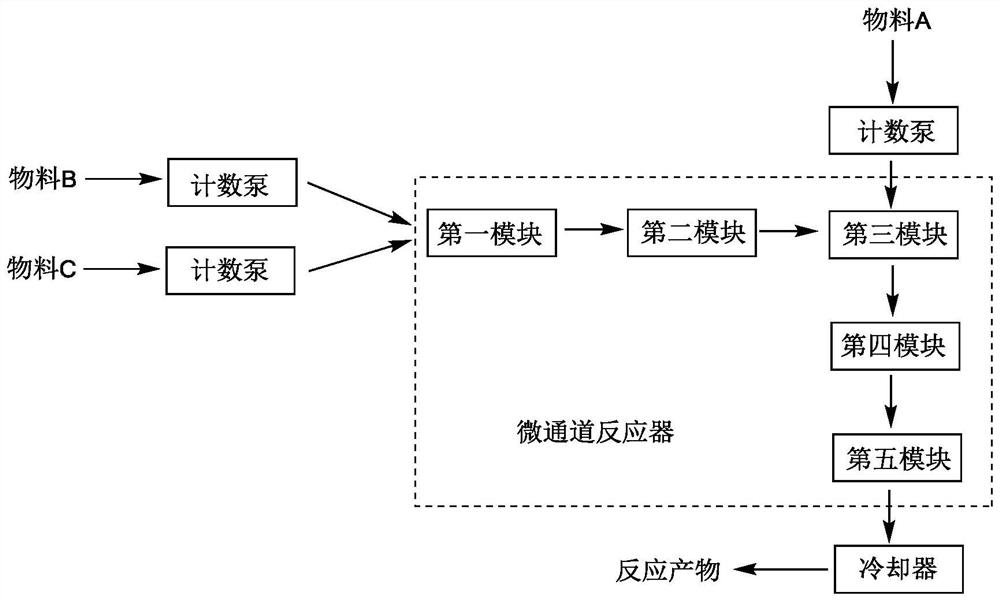

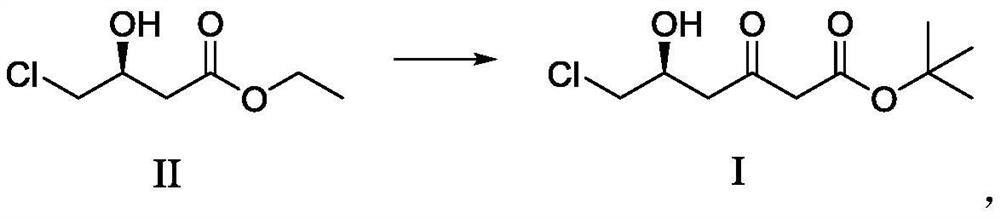

[0036] combine Figure 1-2 Shown, a kind of method utilizing continuous flow microchannel reactor to synthesize rosuvastatin calcium intermediate comprises the following steps:

[0037] (1) Preparation of material A: Compound II (952g, 5.7mol) is added to tetrahydrofuran, diluted to 1.5L, stirred and dissolved, and placed in raw material tank A (the bottom of the raw material tank is fed through a valve corresponding to the microchannel reactor. Pipeline connection), nitrogen protection stand-by.

[0038] (2) Preparation of material B: Lithium diisopropylamide (2.14Kg, 20mol) is added to tetrahydrofuran, diluted to 10.28L, stirred and dissolved, and placed in raw material tank B (the bottom of the raw material tank passes through the valve and the microchannel reactor Corresponding feed pipelines are connected), nitrogen protection stand-by.

[0039] (3) Preparation of material C: tert-butyl acetate (2.58Kg, 22.2mol) was added to tetrahydrofuran, diluted to 11.67...

Embodiment 2

[0043] combine Figure 1-2 Shown, a kind of method utilizing continuous flow microchannel reactor to synthesize rosuvastatin calcium intermediate comprises the following steps:

[0044](1) Preparation of material A: Compound II (952g, 5.7mol) is added in ether, diluted to 1.5L, stirred and dissolved, and placed in raw material tank A (the bottom of the raw material tank is fed through a valve corresponding to the microchannel reactor. Pipeline connection), nitrogen protection stand-by.

[0045] (2) Preparation of material B: Lithium diisopropylamide (1.83Kg, 17.1mol) was added to diethyl ether, diluted to 7.2L, stirred and dissolved, and placed in raw material tank B (the bottom of the raw material tank reacted with the microchannel through a valve) connected to the corresponding feed pipeline of the device), nitrogen protection is for standby.

[0046] (3) Preparation of material C: tert-butyl acetate (2.97Kg, 25.6mol) is added in ether, diluted to 7.5L, stirred and dissolv...

Embodiment 3

[0050] combine Figure 1-2 Shown, a kind of method utilizing continuous flow microchannel reactor to synthesize rosuvastatin calcium intermediate comprises the following steps:

[0051] (1) Preparation of material A: Compound II (952g, 5.7mol) is added to toluene, diluted to 1.5L, stirred and dissolved, and placed in raw material tank A (the bottom of the raw material tank is fed through a valve corresponding to the microchannel reactor. Pipeline connection), nitrogen protection stand-by.

[0052] (2) Preparation of material B: Lithium diisopropylamide (2.44Kg, 22.8mol) is added to toluene, diluted to 12L, stirred and dissolved, and placed in raw material tank B (the bottom of the raw material tank passes through the valve and the microchannel reactor Corresponding feed pipelines are connected), nitrogen protection stand-by.

[0053] (3) Preparation of material C: tert-butyl acetate (2.33Kg, 20mol) is added in toluene, diluted to 15L, stirred and dissolved, and placed in raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com