Low-cost preparation method of L-carnitine

A low-cost, carnitine-based technology, applied in the field of medicine, can solve the problems of increased production equipment, lack of market price competitiveness, high usage of biological enzymes, etc., to reduce the labor of production staff, shorten production time, and simplify synthesis steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

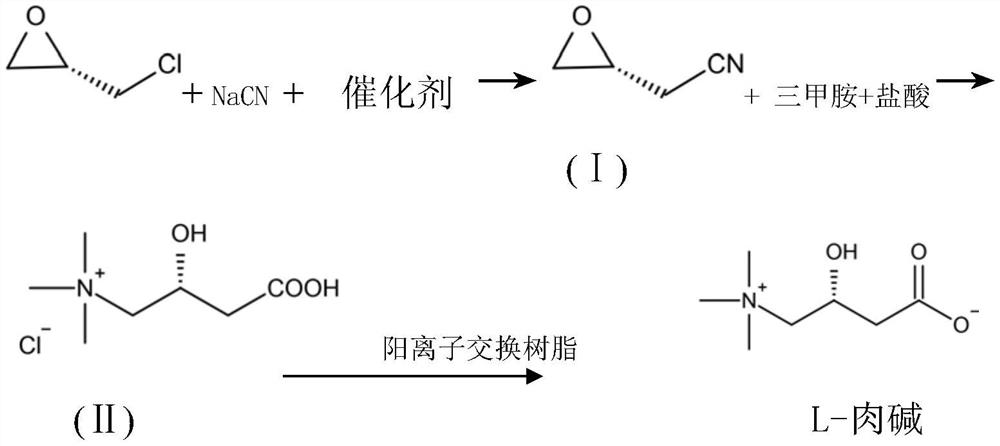

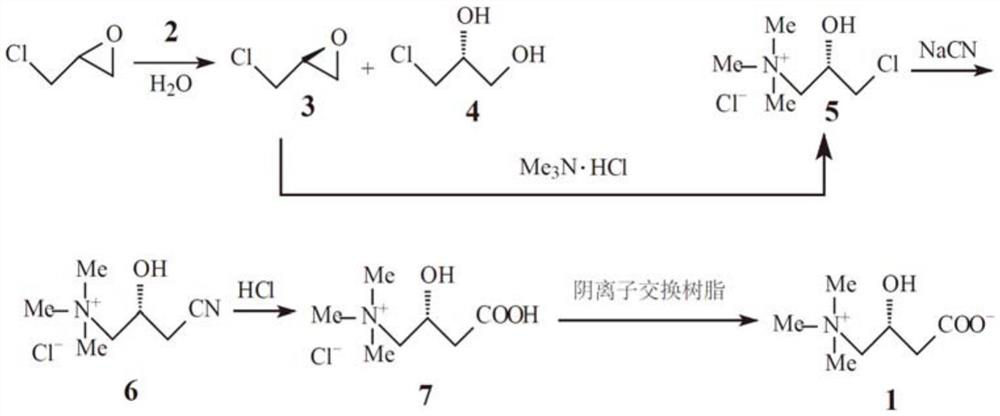

Method used

Image

Examples

Embodiment 1

[0029] 1. Compound (Ⅲ) ethanol solution preparation

[0030]

[0031] Add 200 mL of absolute ethanol and S-epichlorohydrin (100 g, 1081 mmol) to a 1000 ml four-neck flask with a stirring thermometer after drying, and start stirring with benzyltriethylammonium chloride (3 g, 13.2 mmol). When the cold water bath cools down to 20°C, NaCN (55.6g, 1135mmol) is added in 5 times. After the addition is completed, the reaction is stirred at 20-30°C for 5h. The gas chromatography detects that the raw material S-epichlorohydrin has completely reacted, and the reaction is stopped. The filter cake was suction filtered and washed with a small amount of absolute ethanol, and the filtrate was: compound (I) ethanol solution.

[0032] 2. L-carnitine preparation:

[0033]

[0034] Add a 35% hydrochloric acid aqueous solution (338g, 3241mmol) into a 1000ml four-neck flask with a stirring thermometer and start stirring. , the temperature was raised to 40° C., and the ethanol solution of al...

Embodiment 2

[0038] Add 250mL of absolute ethanol and S-epichlorohydrin (110g, 1189mmol) to a 1500ml four-necked flask with a stirring thermometer after drying, and start stirring with benzyltriethylammonium chloride (5g, 21.9mmol). When the temperature in the cold water bath was lowered to 15°C, NaCN (64g, 1308mmol) was added in 5 times. After the addition was complete, the reaction was stirred at 20-30°C for 4h. The reaction of the raw material S-epichlorohydrin was detected by gas chromatography, and the reaction was stopped. Suction filter cake is washed with a small amount of absolute ethanol, and the filtrate is: ethanol solution of compound (I)

[0039] Add a 35% aqueous solution of hydrochloric acid (434g, 4161mmol) into a four-necked flask with a stirring thermometer, start stirring, and when the temperature is lowered to 15°C in a cold water bath, after the dropwise addition of a 33% aqueous solution of trimethylamine (255.5g, 1427mmol), Raise the temperature to 40°C and add drop...

Embodiment 3

[0042] Add 300mL of absolute ethanol and S-epichlorohydrin (150g, 1622mmol) to a 2000ml four-necked flask with a stirring thermometer after drying, and start stirring with benzyltriethylammonium chloride (7g, 30.7mmol). When the temperature in the cold water bath was lowered to 10°C, NaCN (119g, 2433mmol) was added in 5 times. After the addition was completed, the reaction was stirred at 20-30°C for 2h. The reaction of the raw material S-epichlorohydrin was detected by gas chromatography, and the reaction was stopped. The filter cake was suction filtered and washed with a small amount of absolute ethanol, and the filtrate was: ethanol solution of compound (I).

[0043] A concentration of 35% hydrochloric acid aqueous solution (676g, 6488mmol) was added in a four-neck flask with a stirring thermometer, and the stirring was started. Add all the ethanol solutions of compound (I) prepared above at 40°C dropwise, and react at 40-45°C for 3 hours after the dropwise addition, gas chr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com