Temperature sensing material based on trivalent terbium and trivalent europium co-doping and preparation method and application thereof

A sensing material, trivalent europium technology, applied in the field of temperature sensing, can solve the problems of further improvement, change of reaction temperature, application of easily damaged structure, etc., to improve absorption efficiency, improve sensitivity, and obviously change with temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A method for preparing a temperature sensing material based on trivalent terbium and trivalent europium co-doped, comprising the following steps:

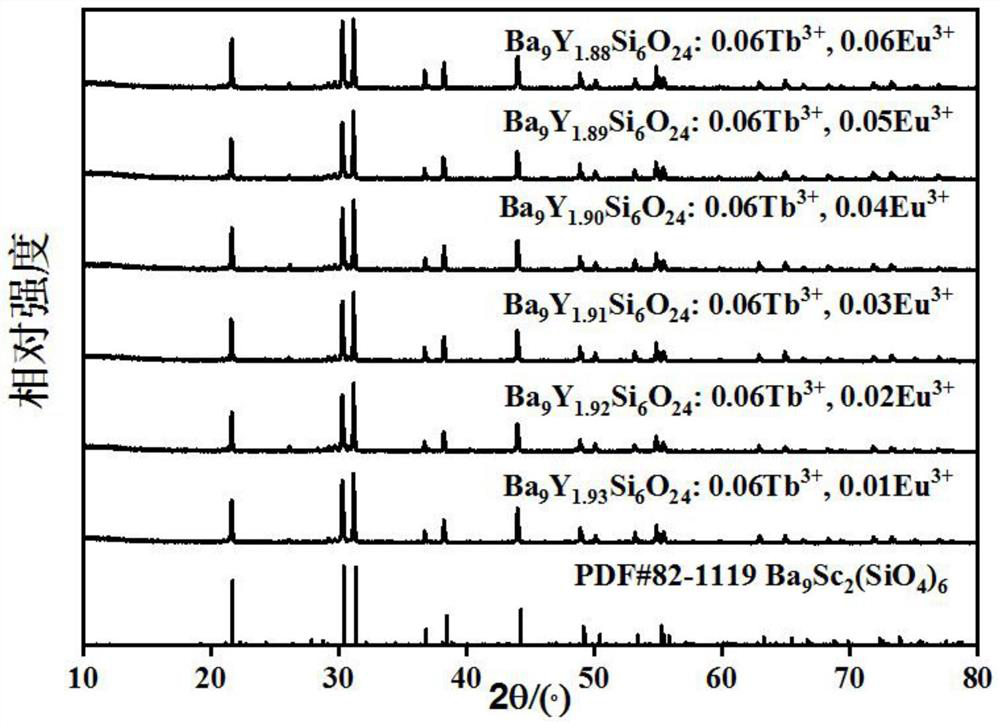

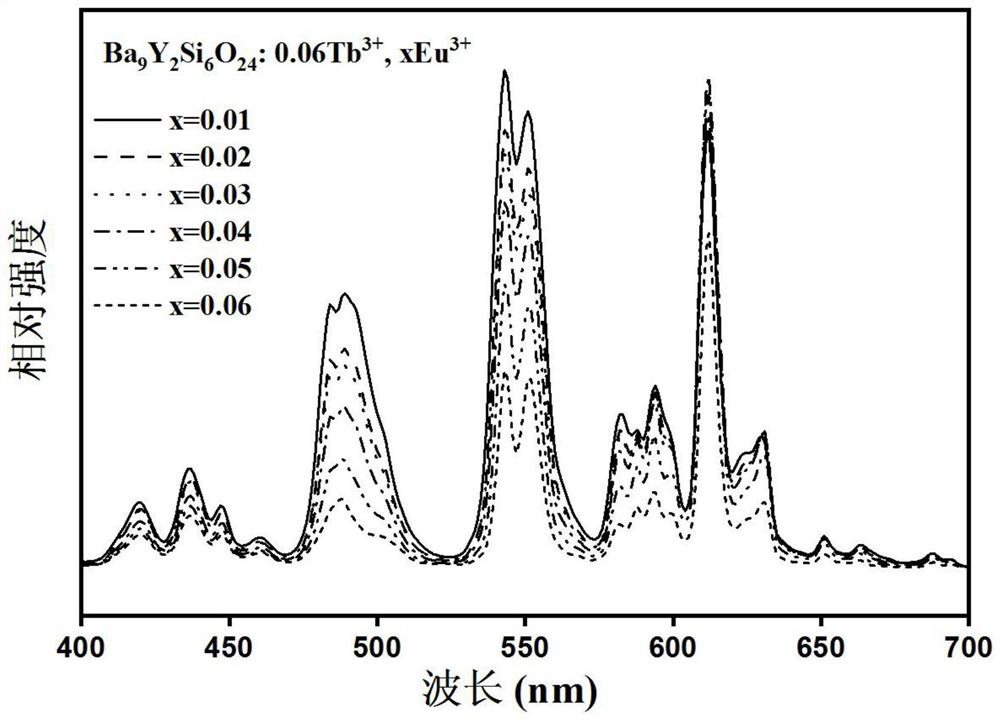

[0052] Step 1: according to the chemical formula Ba of compound 9 Y 2-x-y Si 6 o 24 :xTb 3+ ,yEu 3+ , where x=0.01-0.1, y=0.01-0.1, respectively weigh BaCO according to the stoichiometric ratio 3 , Y 2 o 3 , SiO 2 , Tb 4 o 7 、Eu 2 o 3 to mix;

[0053] In said step one, BaCO 3 , Y 2 o 3 , SiO 2 , Tb 4 o 7 、Eu 2 o 3 The molar ratio of various raw materials is 9:(2-x-y) / 2:6:x / 4:y / 2;

[0054] Step 2: Grinding the mixture in step 1 to obtain a grinding mixture;

[0055] Step 3: sintering the grinding mixture at a high temperature to obtain a massive plate; the three high-temperature sintering temperatures in the step are 1100-1150° C., and sintering for 3-5 hours; the high-temperature sintering heating method is divided into three stages, Specifically:

[0056] The first stage: heat up to 200°C at a heatin...

Embodiment 1

[0061] According to the chemical formula Ba 9 Y 1.9 Si 6 o 24 :0.06Tb 3+ ,0.04Eu 3 Accurately weigh the raw material 0.7496gBaCO 3 ,0.0905gY 2 o 3 ,0.1521gSiO 2 ,0.0047gTb 4 o 7 ,0.0030gEu 2 o 3 . The weighed mixture was fully ground, placed in a high-purity corundum crucible, and transferred to a high-temperature tube furnace. Raise the temperature to 200°C at a rate of 5°C / min and keep it warm for 40 minutes, then raise the temperature to 1000°C at a rate of 10°C / min and keep it for 1 hour. Then the temperature was raised to 1100°C at a rate of 10°C / min and kept for 3h. Then cool down to room temperature at a rate of 10°C / min. A white solid is obtained, and the bulk product is fully ground to obtain the desired fluorescent temperature sensing material in which trivalent terbium and trivalent europium emit light together.

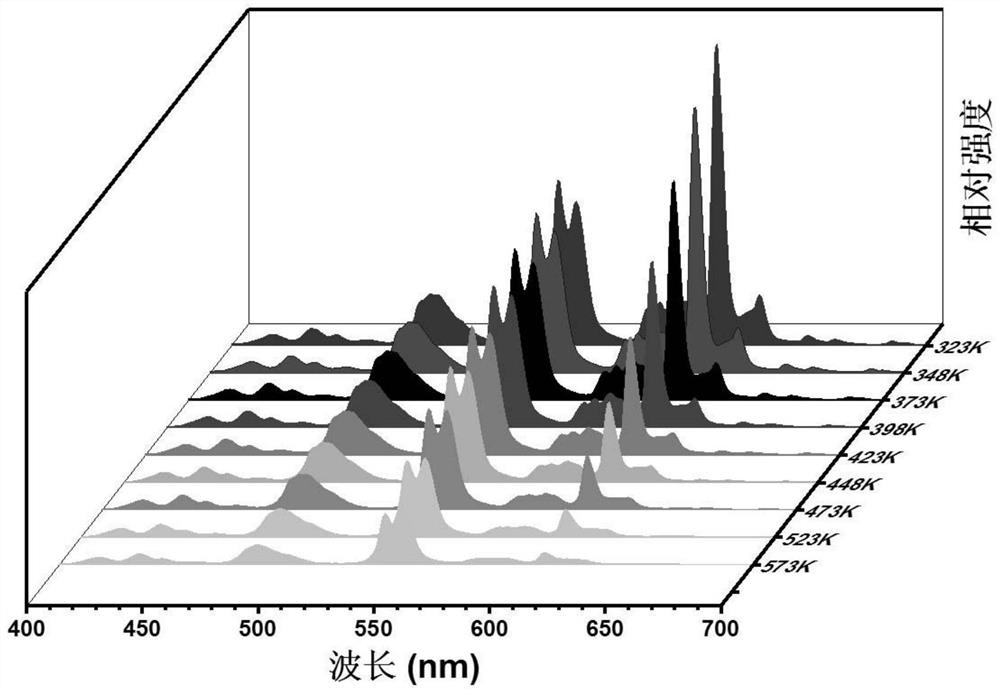

[0062] The emission spectrum of the fluorescent temperature sensing material is tested at different temperatures, and a standard working c...

Embodiment 2

[0065] Embodiment 2 is different from the foregoing examples in that the specific composition of the prepared fluorescent temperature sensing material is Ba 9 Y 1.93 Si 6 o 24 :0.06Tb 3+ ,0.01Eu 3+ , accurately weigh the raw material as 0.7502g BaCO 3 ,0.0920gY 2 o 3 ,0.1523gSiO 2 ,0.0047g Tb 4 o 7 ,0.0007g Eu 2 o 3 . Other steps and parameters are the same as in the foregoing embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com