Heavy aromatic oil processing method

A processing method and technology for heavy aromatics, applied in the petrochemical field, can solve problems affecting BTX yield and catalyst service life, and achieve the effects of avoiding solvent raw material consumption, reducing raw material cost, and increasing pore volume and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

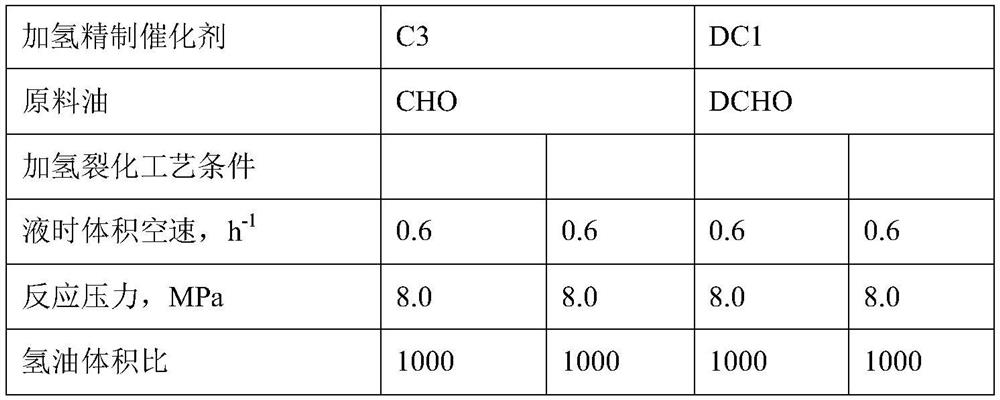

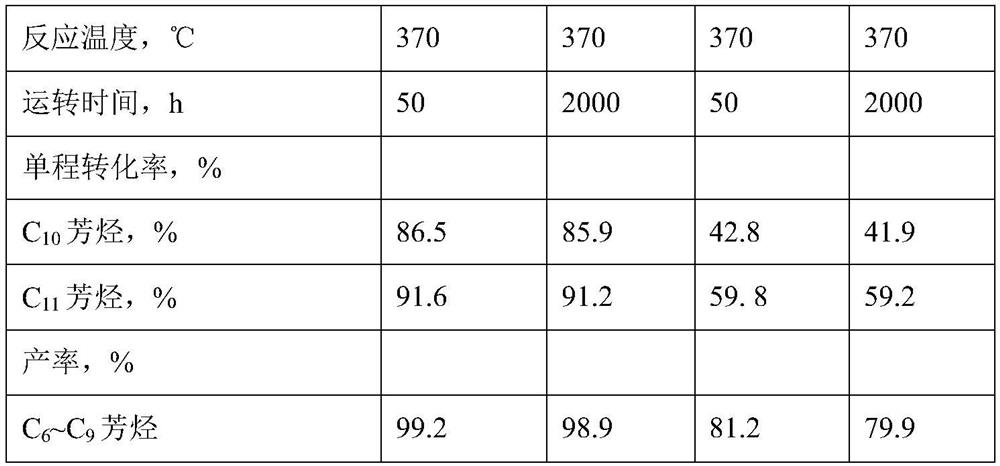

Examples

preparation example Construction

[0062] The preparation method of described hydrorefining catalyst comprises the following steps:

[0063] 1) Drying and pulverizing the natural sponge to obtain natural sponge powder; wherein, the blast drying temperature is 40-55°C, the blast drying time is 10-24h; the blast wind speed is 3-5 m / s; obtained after crushing The particle size of natural sponge powder is 1000-2000 mesh.

[0064] 2) Mix aluminum hydroxide dry rubber powder and natural sponge powder evenly at room temperature, add extrusion aid, extrude into strips, and then perform drying and roasting treatment; wherein, the drying temperature is 100-160°C; the roasting temperature is 400- 650° C., and the calcination time is 1 to 15 hours to obtain the carrier.

[0065] 3) Adding a nonionic surfactant to the aqueous precursor solution of the metal oxide to form an impregnating solution, the precursor being a water-soluble compound corresponding to the metal element; impregnating the carrier obtained in step 2) in...

Embodiment 1

[0071] First, 5.6g of natural sponge is blast-dried, the blower wind speed is 4 m / s, the drying temperature is 45°C, and the blast drying time is 17h, and then pulverized to obtain a natural sponge powder with a particle size of 2000 mesh; the natural sponge powder is dried at room temperature Mix well with 200g aluminum hydroxide dry rubber powder (dry basis is 80%). During the mixing process, add extrusion aids, such as citric acid, in an amount that satisfies the carrier molding; after mixing evenly, the mixture is dried and roasted Get the carrier. Wherein the drying temperature is 160°C, and the drying time is 5 hours; the calcination temperature is 400°C, and the calcination time is 8 hours.

[0072]To the prepared tungsten-cobalt impregnation solution, the concentration is 32.0g metal (calculated as oxide, tungsten / cobalt ratio 3:1) / 100mL solution, 100ml in total, add lauryl alcohol polyether, the amount added is based on the total mass of the carrier Add 2% to 10% of ...

Embodiment 2

[0074] First, 5.0g of natural sponge is blast-dried, the blast speed is 5 m / s, the drying temperature is 50°C, and the blast drying time is 24 hours, and then the natural sponge powder with a particle size of 1000 meshes is obtained by crushing; the natural sponge powder is dried at room temperature Mix well with 200g aluminum hydroxide dry rubber powder (60% on a dry basis). During the mixing process, add extrusion aids, such as citric acid, in an amount that meets the needs of the carrier; after mixing evenly, the mixture is dried and roasted Get the carrier. The drying temperature is 100° C., and the drying time is 7 hours; the calcination temperature is 650° C., and the calcination time is 1 hour.

[0075] To the molybdenum-cobalt impregnation solution prepared above, the concentration is 30.0g metal (calculated as oxide, molybdenum / cobalt ratio 3:1) / 100mL solution is 100ml in total, add lauryl alcohol polyether, the addition amount is based on the total mass of the carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com