Organic-inorganic hybrid perovskite surface interface treatment method, material and application

A processing method and perovskite technology, applied in the direction of organic semiconductor devices, electric solid devices, semiconductor devices, etc., can solve the problems that additive engineering has not been widely used, the dosage and the preparation process are sensitive, and achieve the improvement of device interface electrical and Physical contact, improved device performance and stability, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

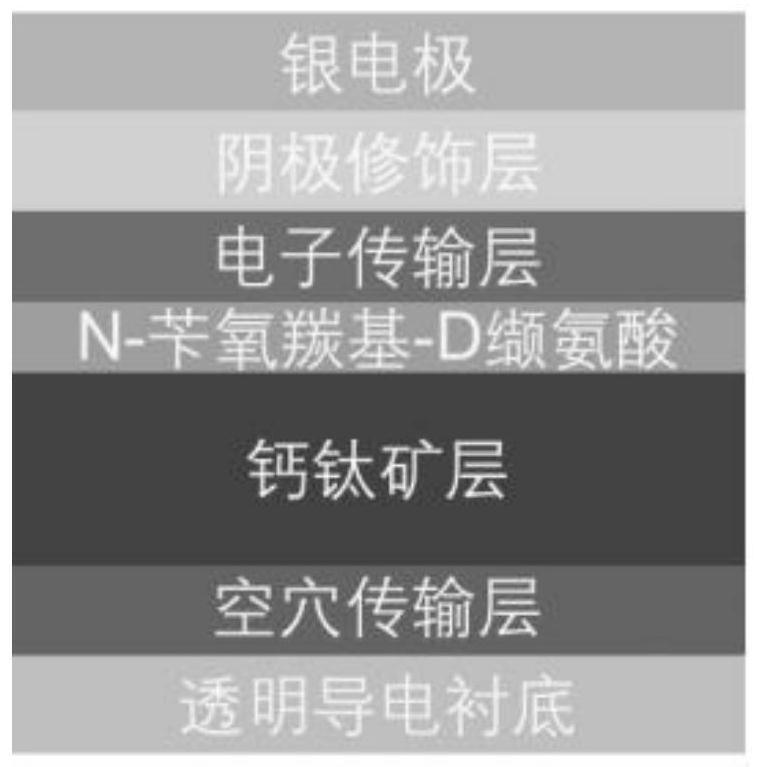

[0056] Such as Figure 7 As shown, an organic-inorganic hybrid perovskite surface interface treatment method, its preparation process is as follows:

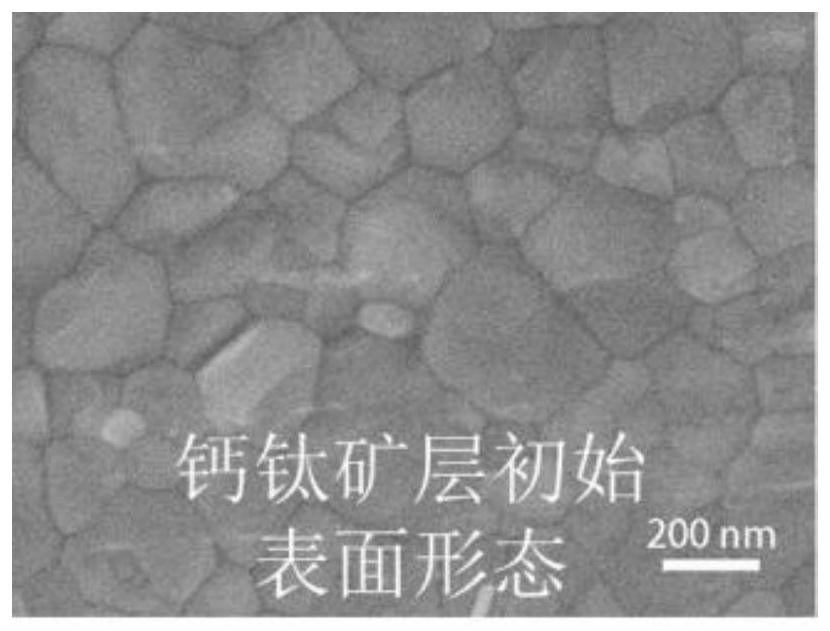

[0057] Step 1). Prepare an organic-inorganic hybrid perovskite film, wherein the perovskite layer material in the organic-inorganic hybrid perovskite film is methylamine lead iodide (MAPbI 3 );

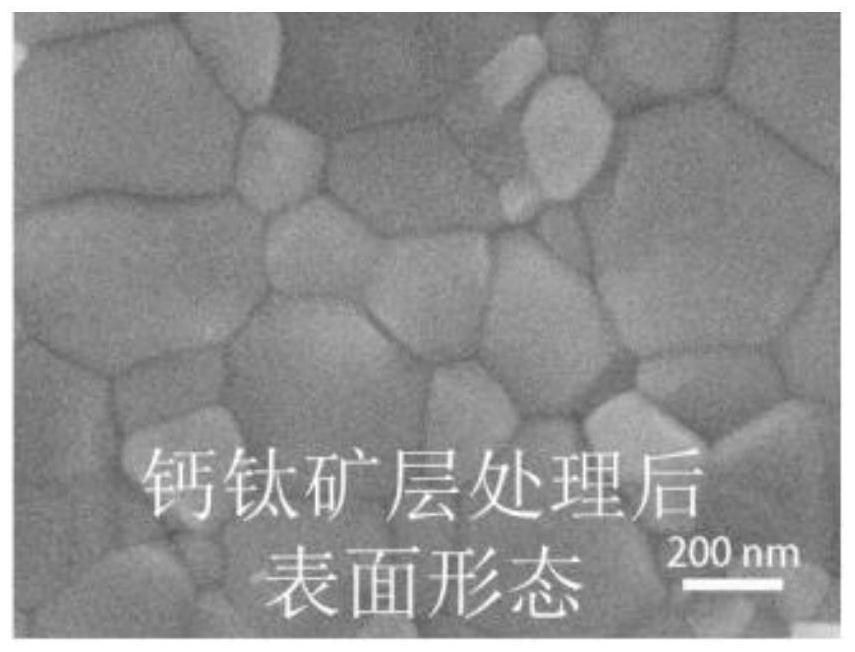

[0058] The surface of the organic-inorganic hybrid perovskite film prepared in step 2) is treated with N-benzyloxycarbonyl-D-valine material, the purity of N-benzyloxycarbonyl-D-valine material is 98%, soluble in Chlorobenzene solution, the treatment solution concentration is 0.05mg / mL, and the treatment method is spin coating;

[0059] Such as figure 1 As shown, the prepared perovskite film is applied in an inverted perovskite solar cell, and its preparation process is as follows:

[0060] Step 1). Spin-coat the hole transport layer on the transparent conductive substrate, the thickness of the hole transport layer is 5nm, heat trea...

Embodiment 2

[0066] A method for treating the surface and interface of an organic-inorganic hybrid perovskite, the preparation method of which is the same as that of Comparative Example 1.

[0067] The prepared perovskite thin film is applied in an inverted perovskite solar cell, and its preparation process is as follows:

[0068] Step 1). Spin-coat the hole transport layer on the transparent conductive substrate, the thickness of the hole transport layer is 5nm, heat treatment at a temperature of 100 ℃, the treatment time is 10 minutes, the transparent conductive substrate is fluorine-doped oxide Tin (FTO), the hole transport layer is poly[bis(4-phenyl)(2,4,6-trimethylphenyl)amine](PTAA);

[0069] Step 2). Spin-coat the perovskite layer with the perovskite film on the hole transport layer described in step 1), the thickness of the perovskite layer is 300nm, heat treatment at 100°C;

[0070] Step 3). The electron transport layer is spin-coated on the surface of the perovskite layer with a...

Embodiment 3

[0074] A method for treating the surface and interface of organic-inorganic hybrid perovskite, the preparation process of which is as follows:

[0075]Step 1). Prepare an organic-inorganic hybrid perovskite film, wherein the perovskite layer material in the organic-inorganic hybrid perovskite film is cesium-doped formamidine methylamine lead-iodine-bromine blended perovskite (Cs x (MA y FA 1-y ) 1-x Pb(I z Br 1-z ) 3 ;1>x>0, 1>y>0, 1>z>0);

[0076] The surface of the organic-inorganic hybrid perovskite film prepared in step 2) is treated with N-benzyloxycarbonyl-D-valine material, the purity of N-benzyloxycarbonyl-D-valine material is 98%, soluble in Chlorobenzene solution, the treatment solution concentration is 0.10mg / mL, and the treatment method is slit coating;

[0077] Step 3). Appropriate heat treatment is performed on the organic-inorganic hybrid perovskite treated in step 2). The heat treatment method is infrared heating. The heat treatment temperature is 100 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com