Solar cell and preparation method thereof

A solar cell and electrode technology, which is applied in the field of solar energy, can solve problems such as poor performance and poor contact, and achieve the effects of improving surface roughness, weakening wettability, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

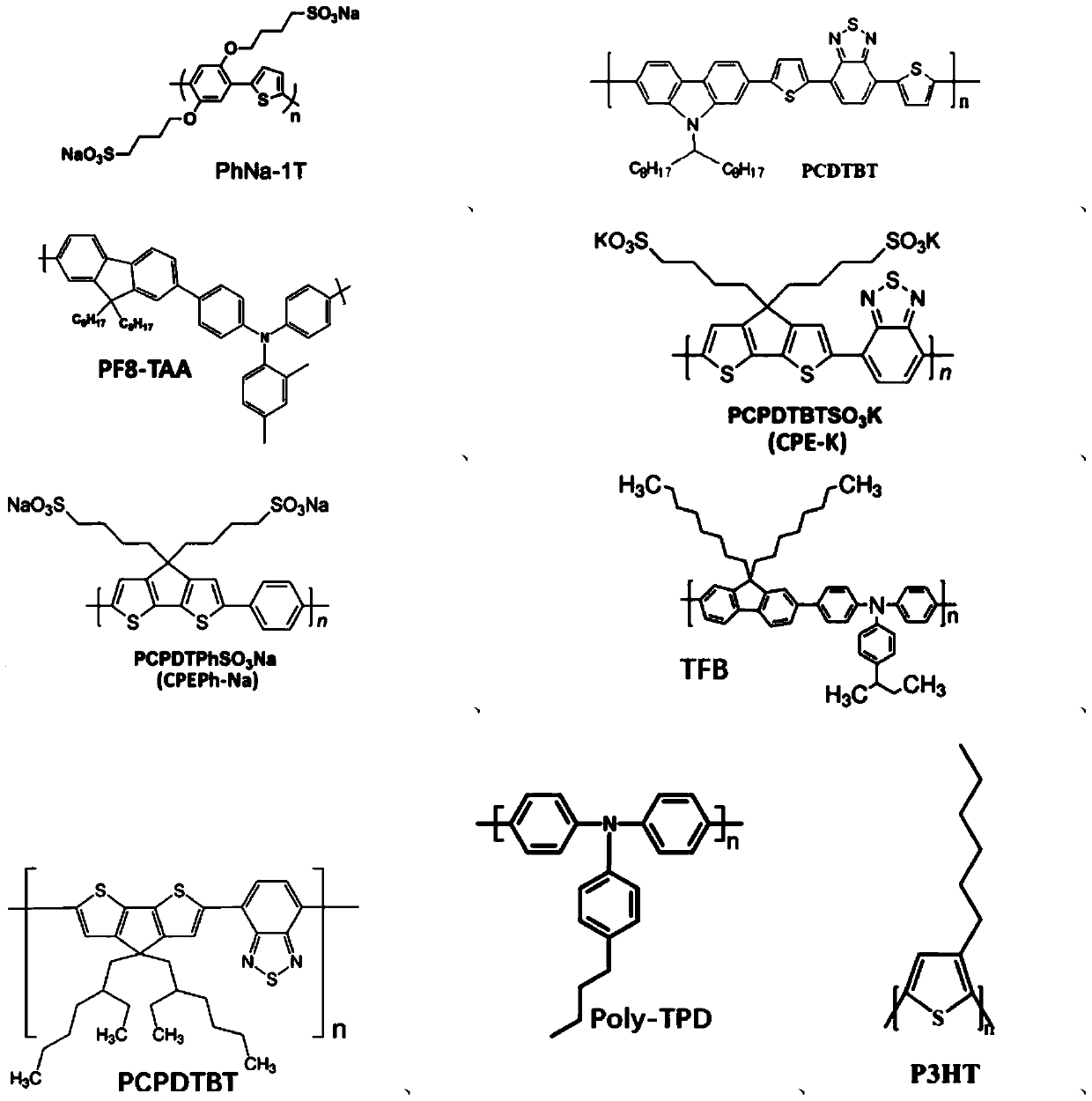

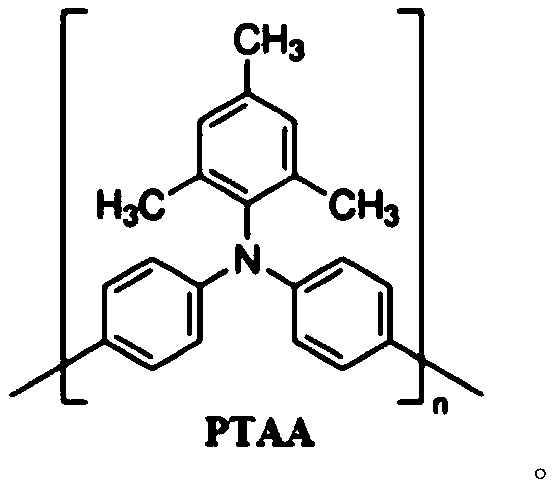

[0043] see figure 1 , this example uses low-temperature nickel oxide as the inorganic hole transport material, PCDTBT as the polymer modification material, and MAPbI 3 It is a perovskite absorbing layer material, PCBM and BCP are used as electron transport materials, and silver is used as a counter electrode.

Embodiment approach

[0044] In this example, the surface defects of nickel oxide are passivated by polymer modification materials, the hole extraction ability is improved, and the crystallinity of perovskite is improved by improving wettability, thus significantly improving the short-circuit current and fill factor of the device. Concrete implementation scheme is as follows:

[0045] (1) Preparation of inorganic hole transport layer 2:

[0046]The low-temperature nickel oxide layer was prepared by the spin coating method, and the 20mg / mL low-temperature nickel oxide spin-coating solution was ultrasonically charged for 10 minutes, and filtered with a 0.45um water filter head for later use. During spin coating, spread the spin coating solution on the surface of the clean conductive glass-transparent electrode 1, spin coating at 3000rpm and 2500rpm / s for 30s, and place it on a heating table for 20 minutes at 120°C after spinning.

[0047] (2) Preparation of Polymer Modification Layer 3:

[0048] Pr...

Embodiment 2

[0070] see figure 1 structure, this example uses CuSCN as the inorganic hole transport material, uses P3HT as the polymer modification material, and uses MAPbI 3 It is a perovskite absorbing layer material, PCBM and BCP are used as electron transport materials, and silver is used as a counter electrode.

[0071] In this example, the surface defects of CuSCN are passivated by polymer modification materials, the hole extraction ability is improved, and the crystallinity of perovskite is improved by improving wettability, so the short-circuit current and fill factor of the device are significantly improved. Concrete implementation scheme is as follows:

[0072] (1) Preparation of inorganic hole transport layer 2:

[0073] The CuSCN inorganic hole-transporting layer is prepared by electrochemical deposition, and the preparation includes 12mM copper sulfate, 12mM ethylenediaminetetraacetic acid and 12mM potassium thiocyanate aqueous solution, at the relative Ag / AgCl (3M KCl) elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com