Polishing pad employing polyamine and cyclohexanedimethanol curing agents

A technology of cyclohexane dimethanol and polishing pads, which is applied in the field of polishing pads, can solve the problems of high cost and achieve the effects of long pad life, good planarization efficiency, and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0026] Example diamines may include aniline diamine compounds, toluene diamine compounds, aminobenzoate compounds, and mixtures thereof. Example aniline diamine compounds include 4,4-methylenebis(2-chloroaniline) (MBCA or MOCA); 4,4'-methylene-bis-o-chloroaniline (MbOCA); 4,4'-methylene Methyl-bis-(3-chloro-2,6-diethylaniline) (MCDEA); 4,4'-methylene-bis-aniline; and 1,2-bis(2-aminophenylthio) ) ethane. Example toluenediamine compounds include dimethylthiotoluenediamine; diethyltoluenediamine; 5-tert-butyl-2,4-toluenediamine; and 3-tert-butyl-2,6-toluenediamine; 5 - tert-amyl-2,4-toluenediamine and 3-tert-amyl-2,6-toluenediamine; and chlorotoluenediamine. Example aminobenzoate compounds include trimethylene glycol di-p-aminobenzoate; polyoxytetramethylene di-p-aminobenzoate; polyoxytetramethylene mono-p-aminobenzoic acid ester; polyoxypropylene di-p-aminobenzoate; and polyoxypropylene mono-p-aminobenzoate.

[0027] Anilinediamine compounds such as 4,4-methylenebis(2-chloro...

no. 1 approach

[0042] A first embodiment may comprise a chemical mechanical polishing pad comprising a thermoset polyurethane polishing layer comprising an isocyanate terminated urethane prepolymer; a polyamine curing agent; and a cyclohexanedimethanol curing agent, Wherein the molar ratio of polyamine curing agent and cyclohexanedimethanol curing agent of polyamine curing agent to cyclohexanedimethanol curing agent is in the range of about 20:1 to about 1:1.

[0043] The second embodiment may include the first embodiment, wherein the prepolymer is a toluene diisocyanate (TDI) compound or a diphenylmethane diisocyanate (MDI) compound and a polytetramethylene ether glycol (PTMEG) or polymethylene Reaction product of propyl ether glycol.

[0044] The third embodiment may include the first or second embodiment, wherein the prepolymer is an aromatic prepolymer selected from the group consisting of 75D prepolymer, 80D prepolymer, and mixtures thereof.

[0045] The fourth embodiment may include a...

Embodiment 1

[0080] A number of non-porous polishing pad samples were prepared for evaluation of the effect of CHDM on mechanical properties (as described in more detail below in Examples 2-4). Samples are prepared by mixing the prepolymer, diamine curing agent, and optional diol curing agent. The mixture was poured onto a nine inch square preheated mold base where it was compression molded at 260°F for 10 min. The precured pad samples were then released from the mold and cured in a vented oven at a temperature of 200°F for 12 hours. The coupons are then cut into samples for mechanical testing.

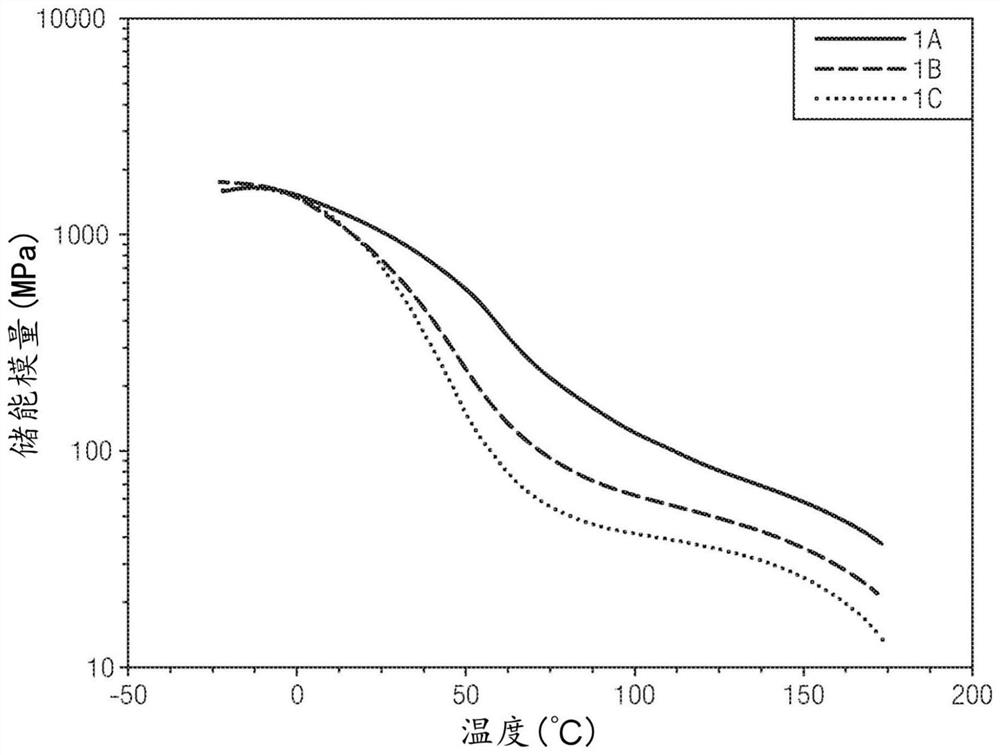

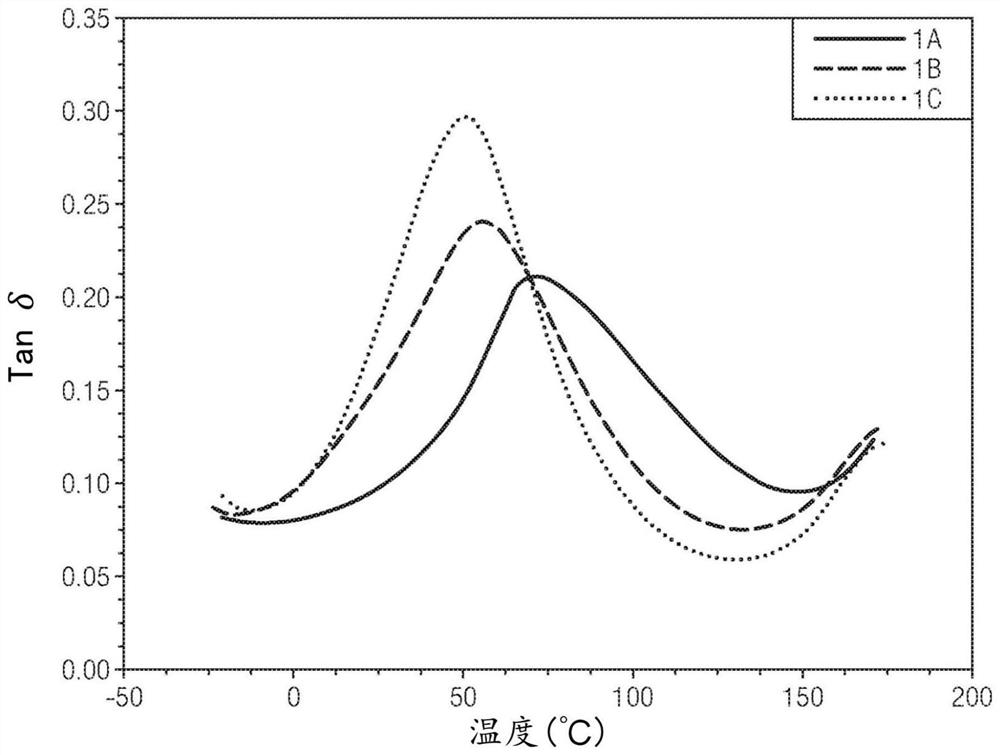

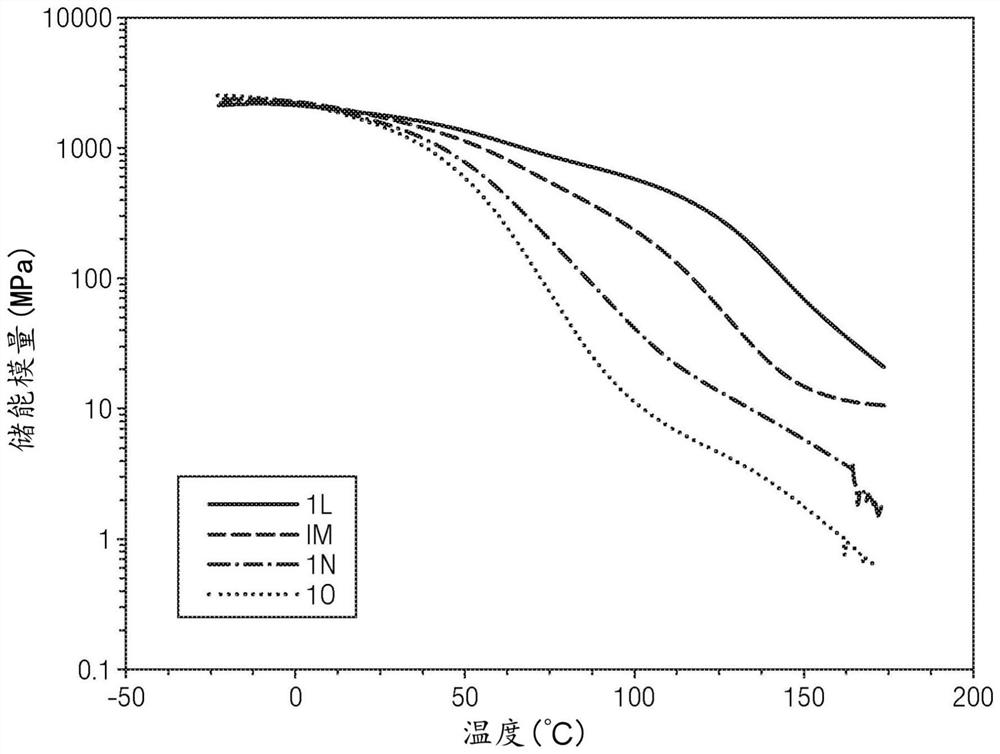

[0081] Table 1A lists 11 experimental pad samples 1A, 1B, 1C, 1D, 1E, 1F, 1G, 1H, 1I, 1J and 1K that included various prepolymer / diamine curing agent / diol compositions . Each of the compositions in Table 1A includes PET-75D prepolymer and dimethylthiotoluenediamine curing agent. Compositions are listed in parts by weight, where each composition is normalized (normalized) to 100 parts by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com