A kind of iridium iron single atom catalyst, preparation method and application

A catalyst and atom technology, applied in the field of iridium-containing iron single-atom catalyst and preparation, can solve the problem of rare research results, achieve the effect of strong anti-CO poisoning ability, increase contact area, and reduce overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

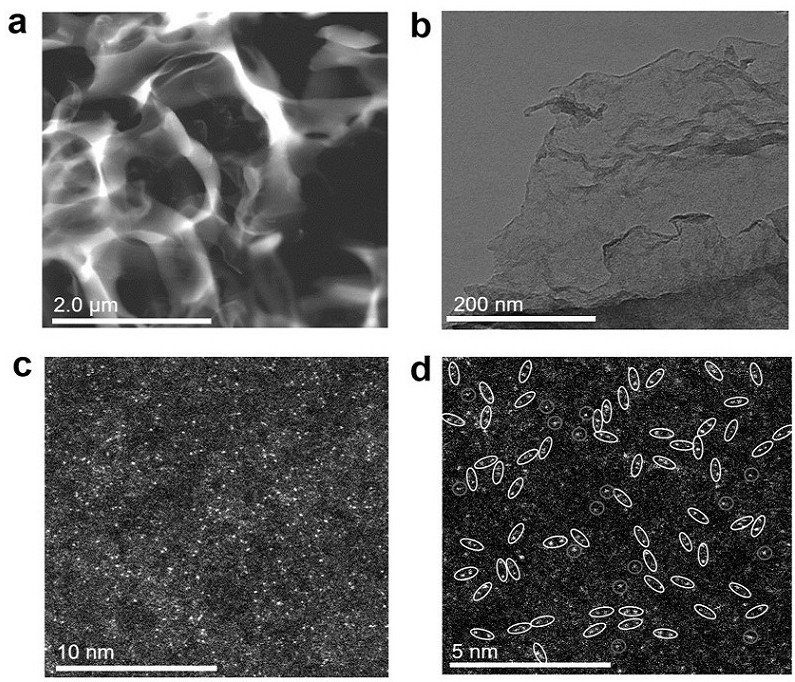

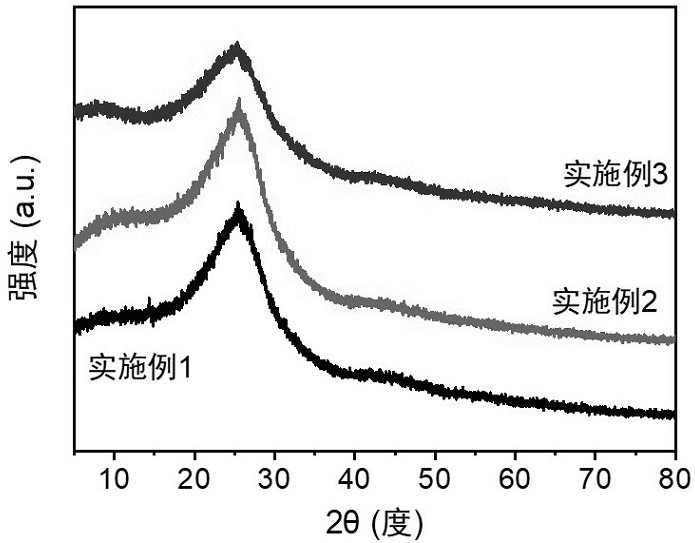

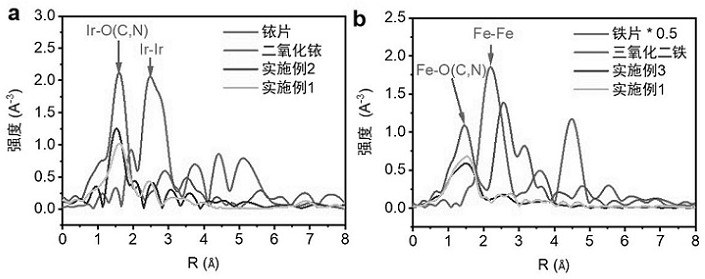

[0030] The present embodiment provides a plurality of preparation methods of crude terephthalic acid hydrorefining IrFe double-atom catalysts and p-carboxybenzaldehyde hydrogenation performance testing process, which specifically includes the following steps:

[0031] First, 360 mg of glucose and 1900 mg of hydroxylamine hydrochloride were dissolved in a water / ethanol solution (water:ethanol=1:1), and stirred at room temperature for 2 hours until a homogeneous and transparent solution was formed, then 5 mg of iridium chloride were respectively weighed and 5 mg of ferric chloride were added, and the above solution was heated at a constant temperature of 80 °C and continued to be stirred for 12 hours until the solution was evaporated completely. The obtained product was collected and then carbonized at 600 °C for 5 h under an argon atmosphere to obtain an IrFe diatomic catalyst. At this time, the loading amount of Ir was 0.1 wt %, and the loading amount of iron was 0.13 wt %.

Embodiment 2

[0033] Ir single-atom catalyst: the specific implementation conditions are the same as in Example 1, except that the amount of iridium chloride in the preparation stage of the catalyst is increased from 5 mg to 10 mg, and the amount of ferric chloride is changed to 0 mg. At this time, the loading amount of Ir was 0.18 wt%.

experiment example 3

[0035] Fe single-atom catalyst: the specific implementation conditions are the same as in Example 1, except that the amount of ferric chloride in the preparation stage of the catalyst is increased from 5 mg to 10 mg, and the amount of iridium chloride is changed to 0 mg. The Fe loading at this time was 0.24 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com