Polyperylene tetracarboxylic diimide, preparation method thereof and application of polyperylene tetracarboxylic diimide in lithium/sodium battery

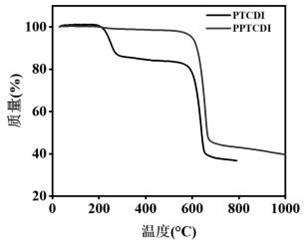

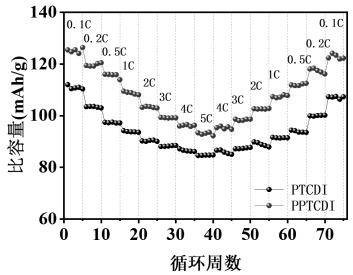

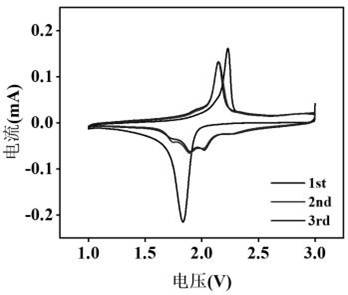

A technology of polyperylene tetracarboximide and perylene tetracarboximide is applied in the field of positive electrode materials for lithium/sodium ion batteries, which can solve the problems of poor cycle performance and high solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Mix perylene tetracarbonyl diimide or polyperylene tetracarbonyl diimide with Super P evenly, dissolve PVDF in NMP and prepare a mass concentration of 3%, then mix the NMP solution containing PVDF with perylene tetracarbonyl diimide Amine or polyperylenetetracarboximide and Super P powders were mixed and ground for 5-10 min, wherein the mass ratio of perylenetetracarboximide or polyperylenetetracarboximide, Super P and PVDF was 70 :20:10, the total mass of the three weighed is 0.1 g. After mixing, quickly spread it on a copper foil with a thickness of 10 μm, then place it in an oven at 60 °C to dry overnight, and cut it with a cutting machine to obtain a positive electrode sheet with a diameter of 13 mm. The loading of perylenetetracarboximide on copper foil is 0.8 mg cm -2 ~1.2 mg cm -2 . 1 M NaPF as the liquid electrolyte for Na-ion batteries 6 ethylene carbonate / diethyl carbonate / propylene carbonate (volume ratio 45:45:10) solution, the amount added is 120-150 μL...

Embodiment 2

[0048] When assembling a lithium-ion battery, the preparation of the positive electrode sheet is the same as in Example 1, and the loading capacity of the active material (perylenetetracarboximide or polyperylenetetracarboximide, the same below) is 0.9 mg cm -2 ~1.0 mg cm -2 . The selected liquid electrolyte is 1 MLiPF 6 Ethylene carbonate / dimethyl carbonate / ethyl methyl carbonate (volume ratio 1:1:1) solution, the addition volume is 120-150 μL, the separator is polypropylene (Celgard 2500), and the thickness is 0.45 mm lithium sheet Do the negative pole.

Embodiment 3

[0050] Replace Super P in Example 1 with carbon nanotubes, and other steps are the same as in Example 1 to prepare a positive electrode sheet for a sodium-ion battery, wherein the active material loading is 0.7 mg cm -2 ~1.0 mg cm -2 . 1 M NaPF as the liquid electrolyte for Na-ion batteries 6 The solution of ethylene carbonate / diethyl carbonate / propylene carbonate (volume ratio 45:45:10) was added in an amount of 120-150 μL, and the septum was glass fiber (Whatman, pore size 2.7 μm), with a thickness of 0.45 mm The sodium sheet is used as the negative electrode, and the sodium-ion battery is assembled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com