Cooling liquid suitable for multi-wire cutting of solar-grade large-size silicon wafer

A multi-wire cutting, solar-grade technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of increased requirements for dispersibility and wettability, insufficient wetting and lubricating ability, edge collapse, and increased dirt, etc. To achieve the effect of excellent penetration, enhanced wettability, and excellent wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a cooling liquid suitable for multi-wire cutting of solar-grade large-size silicon wafers, which includes, in parts by weight, dispersant: 20 parts, wetting agent: 12 parts, and the balance is pure water. The above groups The sum of the points is 100.

[0024] In this example, the dispersant is a cyclodextrin polyether dispersant, with cyclodextrin as the initiator, grafted with ethylene oxide and propylene oxide polymers, the structure is as follows:

[0025]

[0026] Wherein, the degree of polymerization of polyoxyethylene ether is n=7, and the degree of polymerization of polyoxypropylene ether is m=4.

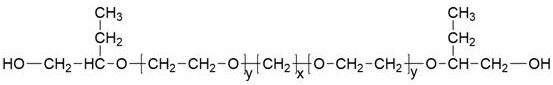

[0027] In this embodiment, the wetting agent is di-hanging glycol polyoxyethylene ether terminated by butylene oxide, and the initiator of the wetting agent is 1,7-heptanediol, 1,7-heptanediol A polymer grafted with ethylene oxide at both ends, and then capped with butylene oxide, the structure is as follows:

[0028]

[0029] Wherein,...

Embodiment 2

[0031] This embodiment provides a cooling liquid suitable for multi-wire cutting of solar-grade large-size silicon wafers, which includes, in parts by weight, dispersant: 22 parts, wetting agent: 15 parts, and the balance is pure water. The above groups The sum of the points is 100.

[0032] In this example, the dispersant is a cyclodextrin polyether dispersant, with cyclodextrin as the initiator, grafted with ethylene oxide and propylene oxide polymers, the structure is as follows:

[0033]

[0034] Wherein, the degree of polymerization of polyoxyethylene ether is n=6, and the degree of polymerization of polyoxypropylene ether is m=4.

[0035] In this embodiment, the wetting agent is di-hanging glycol polyoxyethylene ether terminated by butylene oxide, and the initiator of the wetting agent is 1,8-octanediol, 1,8-octanediol A polymer grafted with ethylene oxide at both ends, and then capped with butylene oxide, the structure is as follows:

[0036]

[0037] Wherein, t...

Embodiment 3

[0039] This embodiment provides a cooling liquid suitable for multi-wire cutting of solar-grade large-size silicon wafers, which includes, in parts by weight, dispersant: 18 parts, wetting agent: 20 parts, and the balance is pure water. The above groups The sum of the points is 100.

[0040] In this example, the dispersant is a cyclodextrin polyether dispersant, with cyclodextrin as the initiator, grafted with ethylene oxide and propylene oxide polymers, the structure is as follows:

[0041]

[0042] Wherein, the degree of polymerization of polyoxyethylene ether is n=8, and the degree of polymerization of polyoxypropylene ether is m=3.

[0043] In this embodiment, the wetting agent is di-hanging glycol polyoxyethylene ether terminated by butylene oxide, and the initiator of the wetting agent is 1,9-nonanediol, 1,9-nonanediol A polymer grafted with ethylene oxide at both ends, and then capped with butylene oxide, the structure is as follows:

[0044]

[0045] Wherein, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com