Oxygen-enriched roasting method of high-copper low-sulfur copper sulfide concentrate and cathode copper

A technology of oxygen-enriched roasting and copper sulfide, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of low conversion rate of acid production and low copper leaching rate, and achieve high comprehensive recovery rate and high recovery rate , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

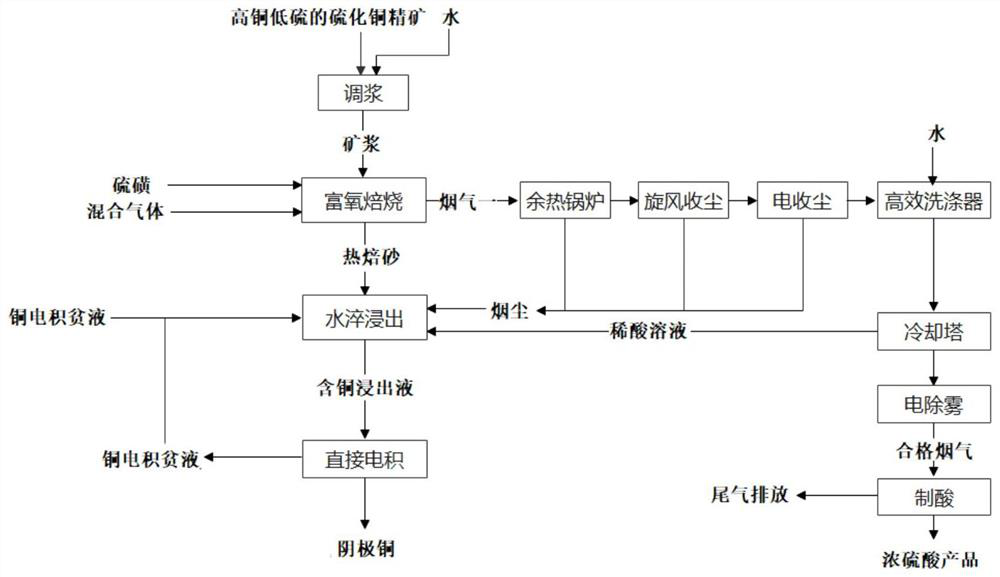

[0050] S1. Prepare copper sulfide dry concentrate (moisture content < 10%) containing 61.88% copper, 0.85% iron and 14.73% sulfur with a certain amount of water in a slurry tank, and stir for 6 hours to make pulp. The mass concentration is 76%;

[0051] S2. Atomize the ore pulp through the atomizer, and then spray it into the roasting furnace. The dry weight input is 11.5t / h, and spray sulfur into the roasting furnace. The injection volume is 1022.3kg / h, and the mixed gas of oxygen and air is introduced into the air chamber of the boiling roaster. The oxygen content concentration of the mixed gas is 32%, and the flow rate of the mixed gas is 18400 m 3 / h, the temperature of oxygen-enriched roasting is 754℃~758℃, and the furnace bottom pressure is 18.4kpa, and oxygen-enriched roasting is carried out to obtain flue gas and hot calcining;

[0052] S3. Pass the flue gas obtained in step S2 through the waste heat boiler (the outlet temperature is 390°C), the cyclone dust collector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com