Preparation method of high-strength and high-elongation clay sand as-cast QT700-10 ductile iron casting

A high-strength, clay-sand technology, used in the preparation of high-strength clay-sand cast QT700-10 ductile iron castings, high-strength field, can solve the problem of high strength and high elongation, low yield strength technical indicators, and poor mechanical performance stability and other issues, to achieve the effect of environmental protection, little influence of human factors, and high stability of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a high-strength, high-strength clay sand-cast QT700-10 ductile iron casting, which is characterized in that it comprises the following steps:

[0030] Step 1. Add recarburizer, scrap steel briquette, furnace charge, and pretreatment agent into the intermediate frequency electric furnace by batch weighing according to the ingredient list for smelting. When it is close to the tapping temperature, take samples, analyze the composition of molten iron, and adjust the ingredients to make the composition qualified. , adjust the temperature to 1520~1550℃, keep warm for 5~8min, and remove slag several times;

[0031] Step 2. The molten iron is automatically weighed and transferred to the spheroidizing bag. Cu and Sn trace alloys are added to the spheroidizing bag for blasting. remove scum;

[0032] Step 3. The molten iron is transferred to the automatic pouring machine, and silicon barium inoculant is added for inoculation, and slag...

Embodiment 1

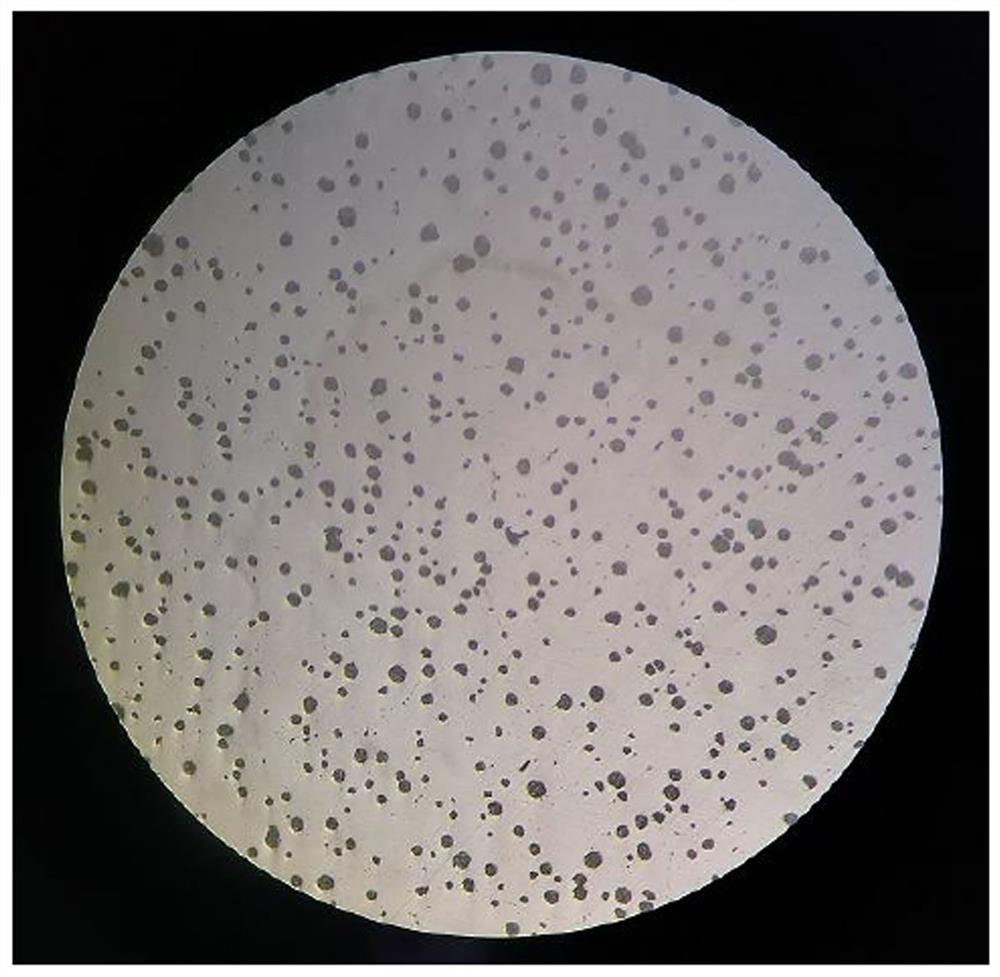

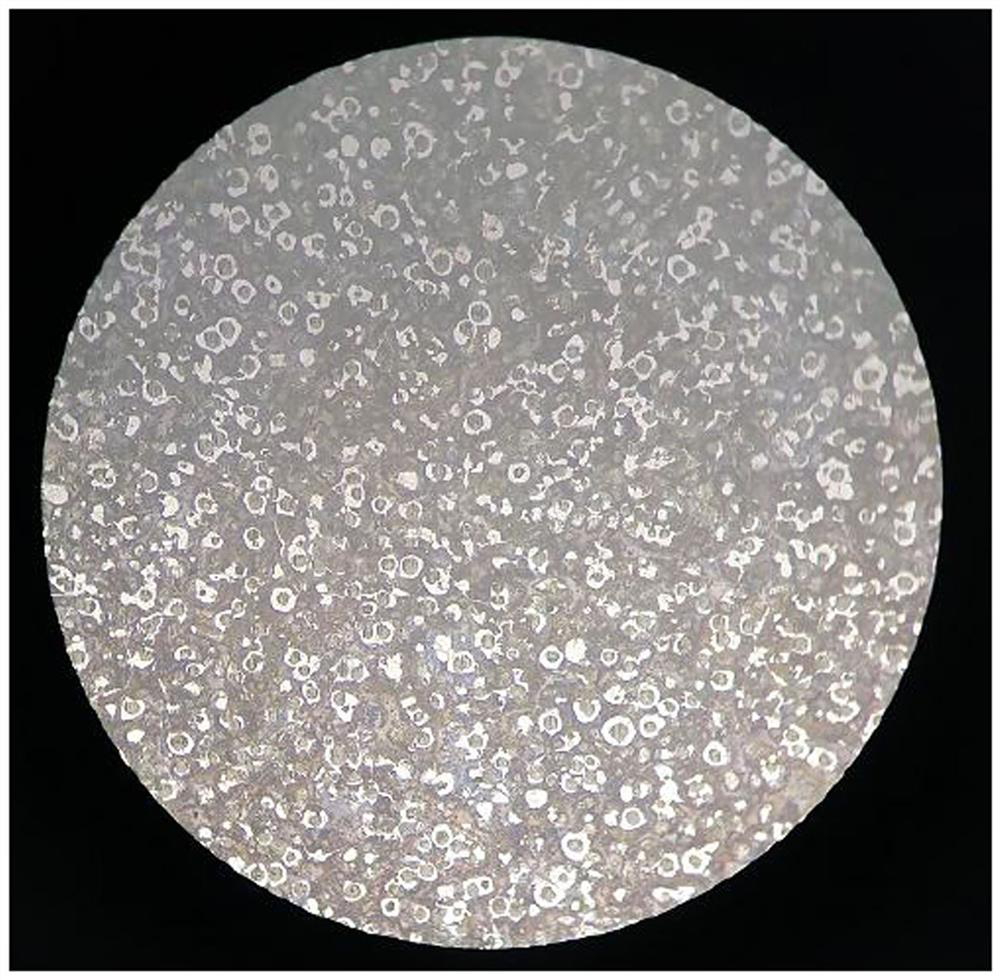

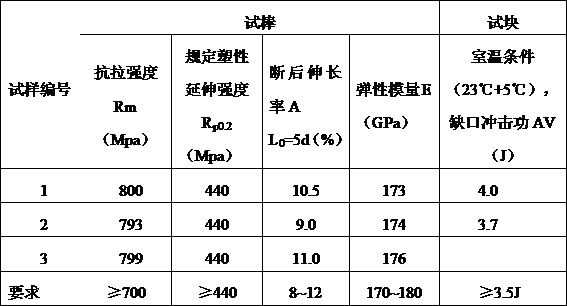

[0041]Raw materials such as scrap steel briquettes, returned materials, recarburizers, silicon carbide and other raw materials are weighed in batches and added to the intermediate frequency electric furnace for melting according to the batch list. When the temperature is close to the tapping temperature, samples are taken to analyze the composition of the molten iron, and the ingredients are adjusted so that the chemical composition of the original molten iron reaches: C3.73%, Si 1.4%, Mn 0.345%, P0.0234%, S0.0092%, Cu0.0658%. After the chemical composition is qualified, the electric furnace is heated up to 1528°C, and the slag is removed for 8 minutes; the molten iron is automatically weighed Re-transfer to the spheroidizing bag, add Cu and Sn trace alloys in the bag for furnace punching; after alloying, the molten iron is automatically transferred for wire feeding and spheroidizing inoculation, the spheroidizing wire and inoculating wire are inserted into the molten iron at th...

Embodiment 2

[0045] Raw materials such as scrap steel briquettes, returned materials, recarburizers, silicon carbide and other raw materials are weighed in batches and added to the intermediate frequency electric furnace for melting according to the batch list. When the temperature is close to the tapping temperature, samples are taken to analyze the composition of the molten iron, and the ingredients are adjusted so that the chemical composition of the original molten iron reaches: C3.73%, Si 1.4%, Mn 0.345%, P0.0234%, S0.0092%, Cu0.0658%, after the chemical composition is qualified, the temperature is raised to 1535°C, and the slag is removed for 6 minutes; the molten iron is automatically weighed Transfer to the spheroidizing bag, add Cu and Sn trace alloys in the bag for furnace punching; after alloying, the molten iron is automatically transferred for wire feeding and spheroidizing inoculation, the spheroidizing wire and inoculating wire are inserted into the molten iron at the same tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com