Preparation method of high-strength and high-resistance multi-scale synergistically-reinforced aluminum-based composite material

A technology for strengthening aluminum-based and composite materials, applied in the direction of electrolytic coating, electrophoretic plating, coating, etc., can solve the problems of restricting the application of materials, difficult mass production of aluminum-based composite materials with high strength and high damping performance, and achieve the goal of overcoming The effect of contradictory strength, high damping performance, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

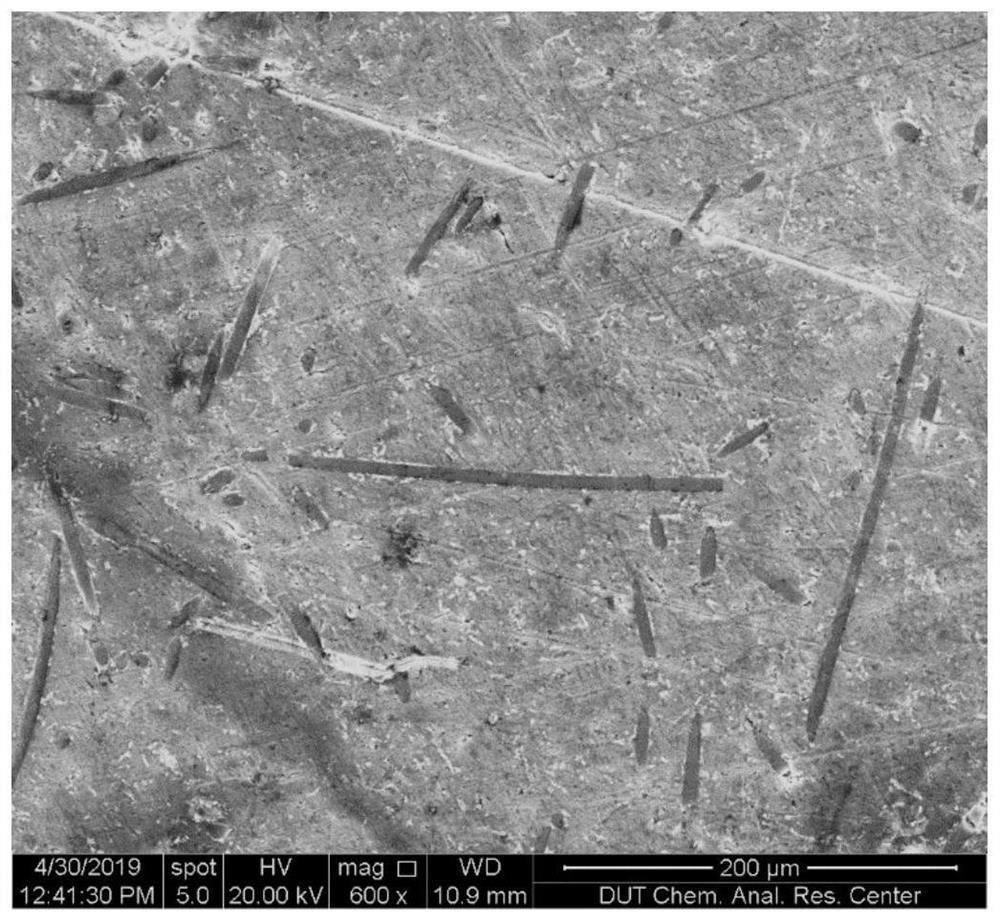

Embodiment 1

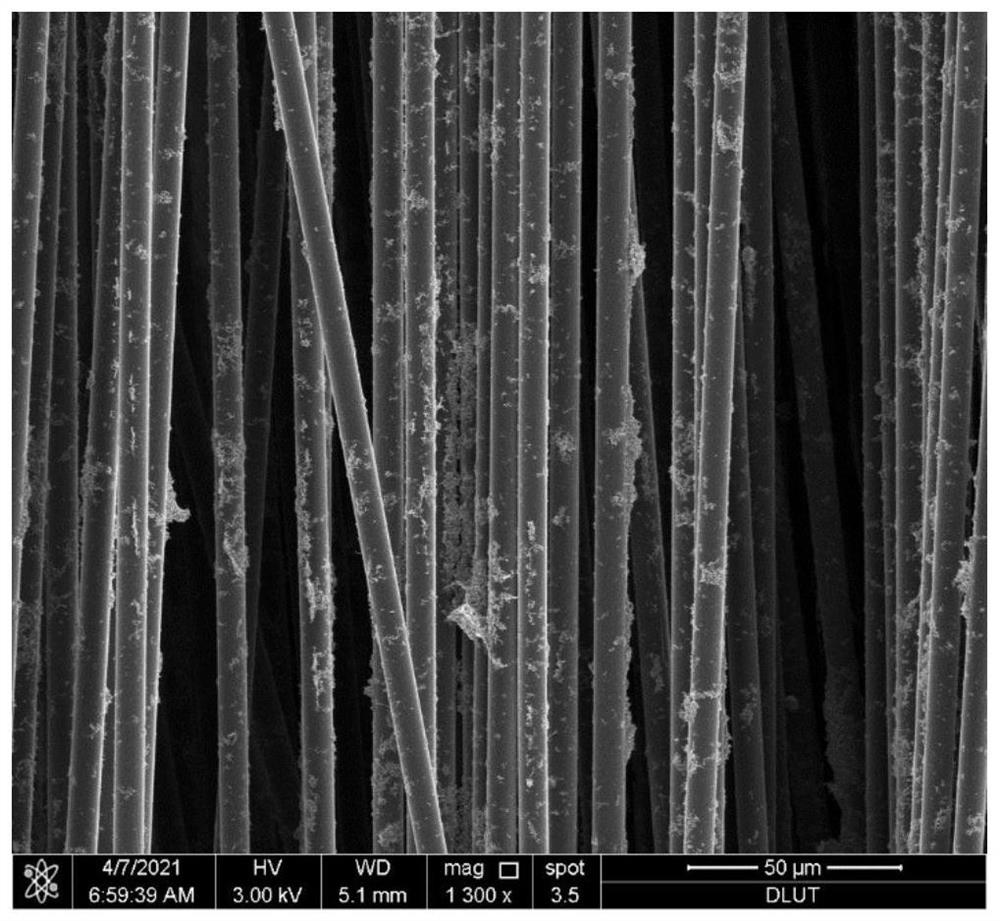

[0027] Embodiment 1: Step 1, electrophoretic deposition of a layer of uneven carbon nanotube coating on the surface of carbon fibers: first, 0.025g of aluminum nitrate nonahydrate was added to 500ml of isopropanol, fully stirred to dissolve it, and then added 0.5 g of carbon nanotubes, oscillate ultrasonically for 40 minutes to evenly disperse the carbon nanotubes; then add the prepared electrophoretic solution into the electrophoresis tank, put the carbon fibers into the electrophoretic solution to electrophoretically deposit carbon nanotubes, connect the carbon fibers to the cathode of the power supply, and graphite electrodes It is connected to the anode of the power supply and adopts a DC power supply. During the electrophoresis process, the temperature of the electrophoretic solution is 25°C, the voltage is 60V, and the electrophoresis time is 40s.

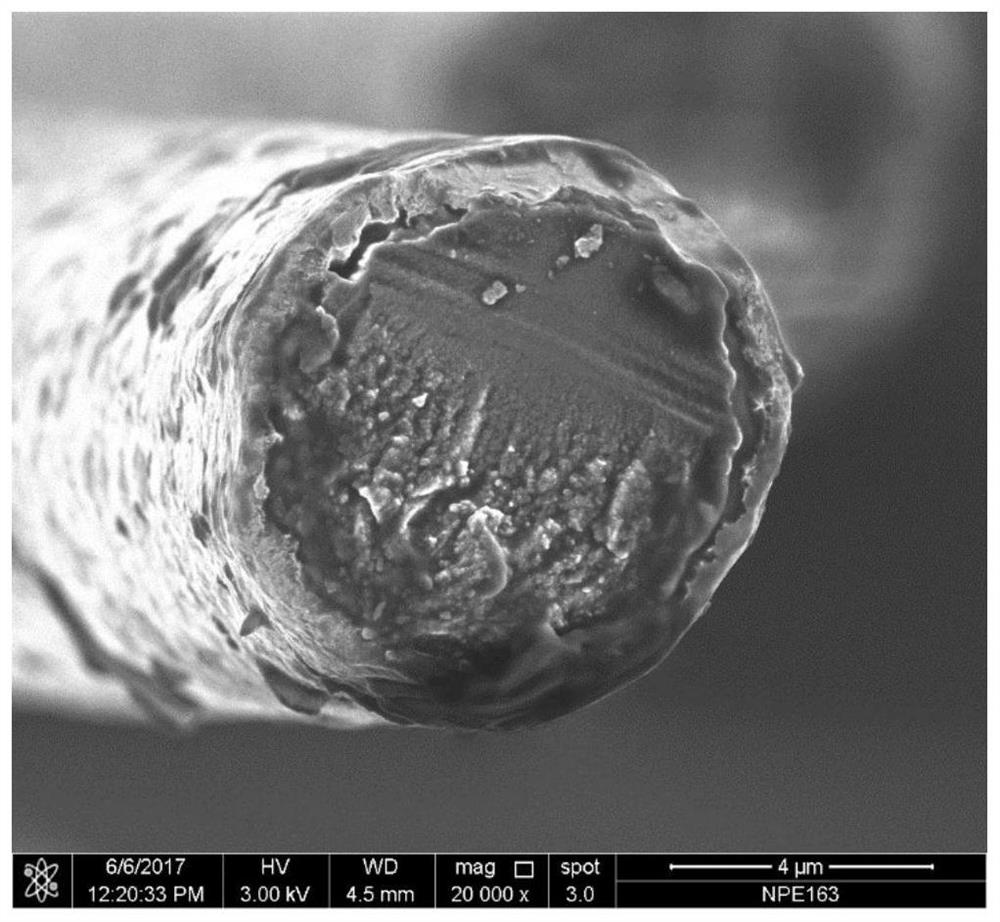

[0028] Step 2, electroplating nickel coating on the carbon fiber surface obtained in step 1: first prepare the electroplatin...

Embodiment 2

[0031] Embodiment 2: Step 1, electrophoretic deposition of a layer of uneven carbon nanotube coating on the surface of carbon fiber: first, 0.015g of aluminum nitrate nonahydrate is added to 500ml of isopropanol, fully stirred to dissolve it, and then add 0.4 g of carbon nanotubes, ultrasonically oscillate for 30 minutes to evenly disperse the carbon nanotubes; then add the prepared electrophoretic solution into the electrophoresis tank, put the carbon fibers into the electrophoretic solution to electrophoretically deposit carbon nanotubes, connect the carbon fibers to the cathode of the power supply, and graphite electrodes It is connected to the anode of the power supply and adopts a DC power supply. During the electrophoresis process, the temperature of the electrophoretic solution is 30°C, the voltage is 90V, and the electrophoresis time is 60s.

[0032] Step 2, electroplating a nickel coating on the surface of the carbon fiber obtained in step 1, first prepare an electropl...

Embodiment 3

[0035] Embodiment 3: Step 1, electrophoretic deposition of a layer of uneven carbon nanotube coating on the surface of carbon fiber: first, 0.04g of aluminum nitrate nonahydrate was added to 500ml of isopropanol, fully stirred to dissolve it, and then added 0.75 g of carbon nanotubes, oscillate ultrasonically for 60 minutes to disperse the carbon nanotubes evenly; then add the prepared electrophoresis solution into the electrophoresis tank, put the carbon fibers into the electrophoresis solution to deposit carbon nanotubes by electrophoresis, connect the carbon fibers to the cathode of the power supply, and graphite electrodes It is connected to the anode of the power supply and adopts a DC power supply. During the electrophoresis process, the temperature of the electrophoretic solution is 15°C, the voltage is 40V, and the electrophoresis time is 30s.

[0036] Step 2, electroplating nickel coating on the carbon fiber surface obtained in step 1: first deploy the electroplating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com