Method for displacing oil by using microbial in-situ microemulsion system

A technology of microorganisms and microbial activators, which is applied in the field of oil displacement using microbial in-situ microemulsion system, can solve the problems of limited scope of microemulsion oil displacement technology, reducing the interaction efficiency between the system and crude oil, and the influence of the degree of crude oil recovery. Achieve good field test results, save chemical surfactants and co-surfactants, and have strong pertinence and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Test block screening

[0059] Test block A: Reservoir temperature 51°C, crude oil viscosity 760mPa.s, formation water salinity 981mg / L, permeability 1200×10 -3 μm 2 , the concentration in the formation water of test block A is 8.0×10 2 individual / mL Bacillus (surfactant-producing microorganisms); the formation water in test block A still has a concentration of 3.5×10 2 Individual / mL Enterobacteriaceae (surfactant-producing microorganisms), so test block A complies with the oil reservoir screening criteria of the present invention.

[0060] (2) Surfactant-producing microbial activator system screening

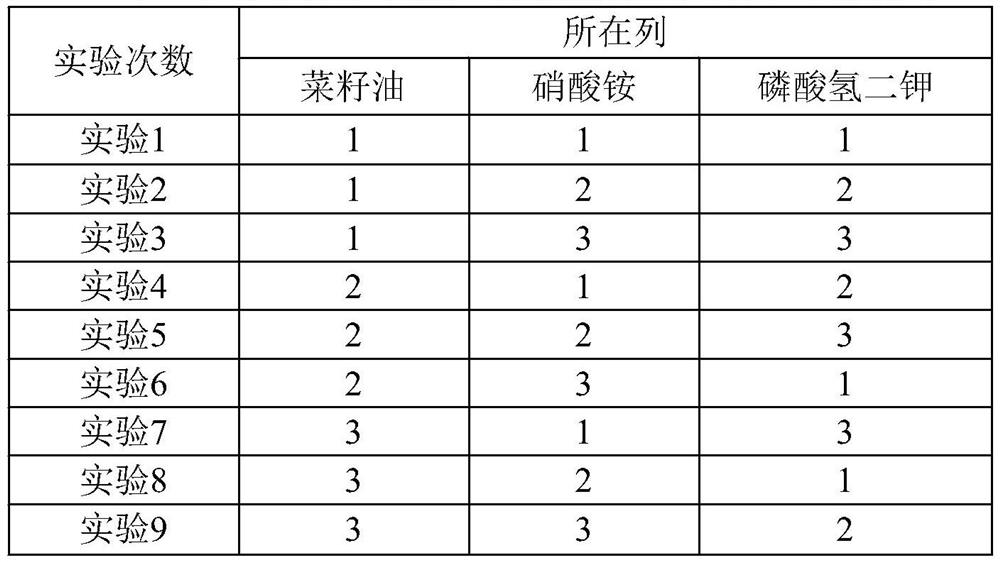

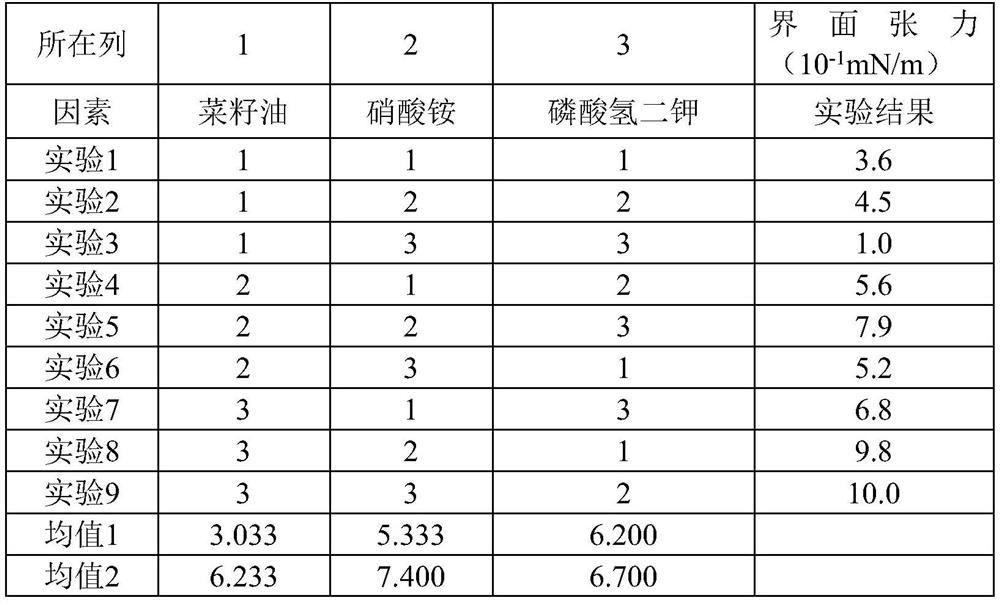

[0061] Take 100mL of formation water in the test block A of the area and place it in a culture bottle, and then add rapeseed oil (carbon source), ammonium nitrate (nitrogen source) and dipotassium hydrogen phosphate in the surfactant microbial activator system to the culture bottle (Phosphorus source), static culture at 51°C for 10 days, using orthogonal experimen...

Embodiment 2

[0109] (1) Test block screening

[0110] Test block B: Reservoir temperature 62°C, crude oil viscosity 1260mPa.s, formation water salinity 1581mg / L, permeability 980×10 -3 μm 2 , the concentration in the formation water of test block B is 2.8×10 2 individual / mL Rhodococcus (surfactant-producing microorganisms), the concentration is 5.2×10 2 Dietzella (surfactant-producing microorganisms) per mL; the concentration of 3.6×10 2 Individual / mL of Lactobacillus (surfactant-producing microorganisms), so the test block B meets the oil reservoir screening criteria of the present invention.

[0111] (2) Surfactant-producing microbial activator system screening

[0112] Take 150mL of formation water from test block B and place it in a culture bottle, then add soybean oil (carbon source), sodium glutamate (nitrogen source), and phosphoric acid dodecahydrate in the surfactant microbial activator system to the culture bottle Sodium hydrogen disodium (phosphorus source) was cultured sta...

Embodiment 3

[0159] (1) Test block screening

[0160] Test block F: Reservoir temperature 72°C, crude oil viscosity 1586mPa.s, formation water salinity 3327mg / L, permeability 2270×10 -3 μm 2 , the concentration in the formation water of test block F is 1.0×10 2 Individual / mL Pseudomonas (surfactant-producing microorganisms), the concentration is 3.0×10 2 individual / mL Rhodococcus (surfactant-producing microorganisms); the concentration of 2.0×10 2 Individual / mL lactobacilli (microsurfactant-producing microorganisms), the test block F meets the oil reservoir screening criteria of the present invention.

[0161] (2) Surfactant-producing microbial activator system screening

[0162] Take 50mL of formation water from test block F and place it in a petri dish, then add rapeseed oil (carbon source), sodium nitrate (nitrogen source), hydrogen phosphate dodecahydrate in the surfactant microbial activator system to the petri dish Disodium (phosphorus source) was cultured statically at 72°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com