Low-resistivity low-temperature solar silver paste and preparation method thereof

A low-resistivity, solar-powered technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of low conversion rate and high production cost of inorganic semiconductor thin-film batteries, and achieve improved flexibility, reduced slurry resistivity and cost Significant resistance, effect of deepening curing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A low-resistivity low-temperature solar silver paste. In terms of mass percentage, the raw materials of the silver paste include the following components: 93% silver powder, 1.5% resin, 1% diluent, 1.2% curing agent, 0.2% thixotropic agent, Catalyst 0.1%, organic solvent 3%.

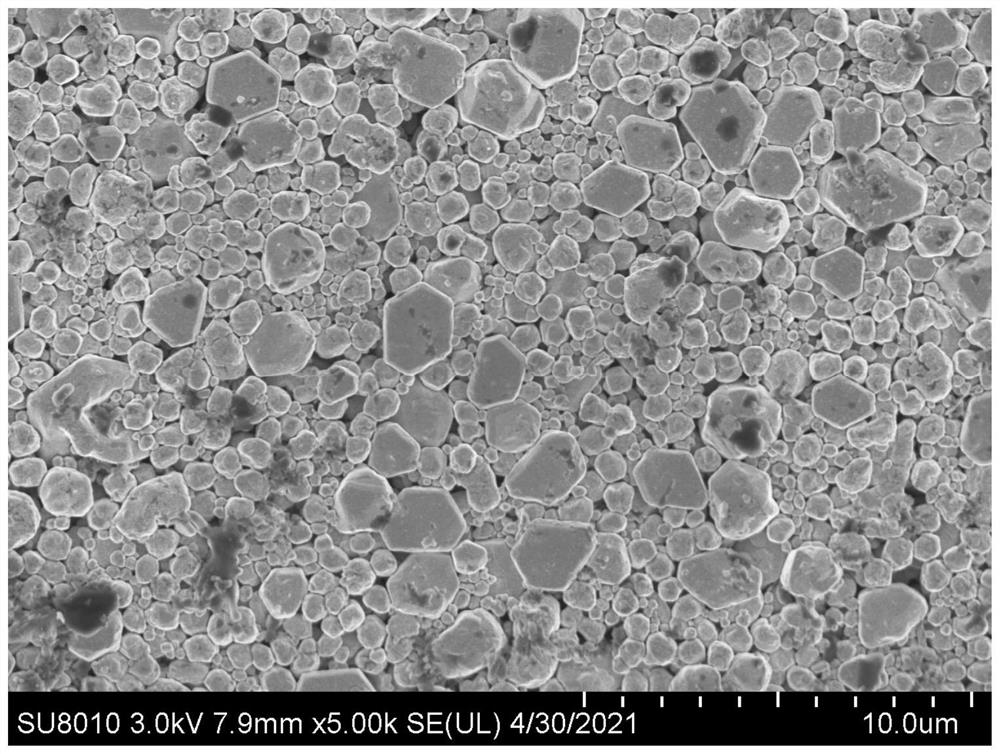

[0039] Among them, the silver powder is flaky powder with a D50 of 3.0 μm and a tap density of 4.5 g / mL at 5% of the slurry, spherical powder with a D50 of 10% of 0.6 μm and a tap density of 4.8 g / mL, and a D50 of 55% of 2 μm. , a spherical powder with a tap density of 6 g / mL and a spherical powder with a 23% D50 of 1 μm and a tap density of 5.8 g / mL. The spherical powder is a ball powder and a ball-like powder.

[0040] Epoxy resin as main resin: 0.5% phenoxy resin PKHH and 0.7% bisphenol A epoxy resin JER827, auxiliary resin: 0.3% 2000ML.

[0041] Diluent: 1% resorcinol diglycidyl ether.

[0042] Curing agent: consists of isocyanate curing agent and auxiliary curing agent, specifically 1% G282...

Embodiment 2

[0053] A low-resistivity low-temperature solar silver paste, comprising the following components by mass percentage: 93% silver powder, 1.5% resin, 1% diluent, 1.2% curing agent, 0.2% thixotropic agent, 0.1% catalyst, organic solvent 3%.

[0054] Among them, the silver powder is flaky powder with a D50 of 3.0 μm and a tap density of 4.5 g / mL at 5% of the slurry, spherical powder with a D50 of 10% of 0.6 μm and a tap density of 4.8 g / mL, and a D50 of 55% of 2 μm. , a spherical powder with a tap density of 6 g / mL and a spherical powder with a 23% D50 of 1 μm and a tap density of 5.8 g / mL, the spherical powder includes spherical powder and spherical powder.

[0055] Epoxy resin as main resin: 0.4% phenoxy resin PKFE and 0.7% bisphenol A epoxy resin JER830S, auxiliary resin: 0.4% 220.

[0056] Diluent: 1% resorcinol diglycidyl ether.

[0057] Curing agent: consists of isocyanate curing agent and auxiliary curing agent, specifically 1% G282 isocyanate curing agent, the unblocking...

Embodiment 3

[0068] A low-resistivity low-temperature solar silver paste, comprising the following components by mass percentage: 93% silver powder, 1.5% resin, 1% diluent, 1.2% curing agent, 0.2% thixotropic agent, 0.1% catalyst, organic solvent 3%.

[0069] Among them, the silver powder is made of silver powder which accounts for 5% of the slurry, D50 is 3.0 μm, and the tap density is 4.5g / mL; 88% D50 is 1 μm, the tap density is 5.8g / mL, D10 is 0.1 μm, D100 is 3μm, spherical powder with wide particle size distribution.

[0070] Epoxy resin as main resin: 0.5% phenoxy resin PKHH and 0.7% bisphenol A epoxy resin JER827, auxiliary resin: 0.3% 2000ML.

[0071] Diluent: 1% resorcinol diglycidyl ether.

[0072] Curing agent: consists of isocyanate curing agent and auxiliary curing agent, specifically 1% G282 isocyanate curing agent, unblocking temperature is 80°C, auxiliary curing agent: 0.2% benzimidazole.

[0073] Thixotropic agent: 0.2% polyamide wax.

[0074] Catalyst: 0.1% XC2007.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com