Lithium ion battery carbon microsphere negative electrode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of spherical carbon materials such as poor sphericity, difficulty in achieving sufficient fineness, and cumbersome preparation process, etc., to achieve increased strength, Improved rate performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A preparation method of carbon microsphere negative electrode material for lithium ion battery:

[0060] (1) Mix 5 grams of carbon black, 5 grams of wheat starch and 200 grams of water, and stir at 50°C for 4 hours to obtain a slurry;

[0061] (2) The slurry obtained in step (1) is dried and formed through the process of spray drying into balls. The spray drying inlet temperature is 230°C, and the outlet temperature is 70~150°C; after drying, initial carbon microspheres can be obtained ;

[0062] (3) The initial carbon microspheres obtained in step (2) were subjected to a high-temperature treatment at 900° C. for 2 h under an argon atmosphere to obtain a carbon microsphere negative electrode material.

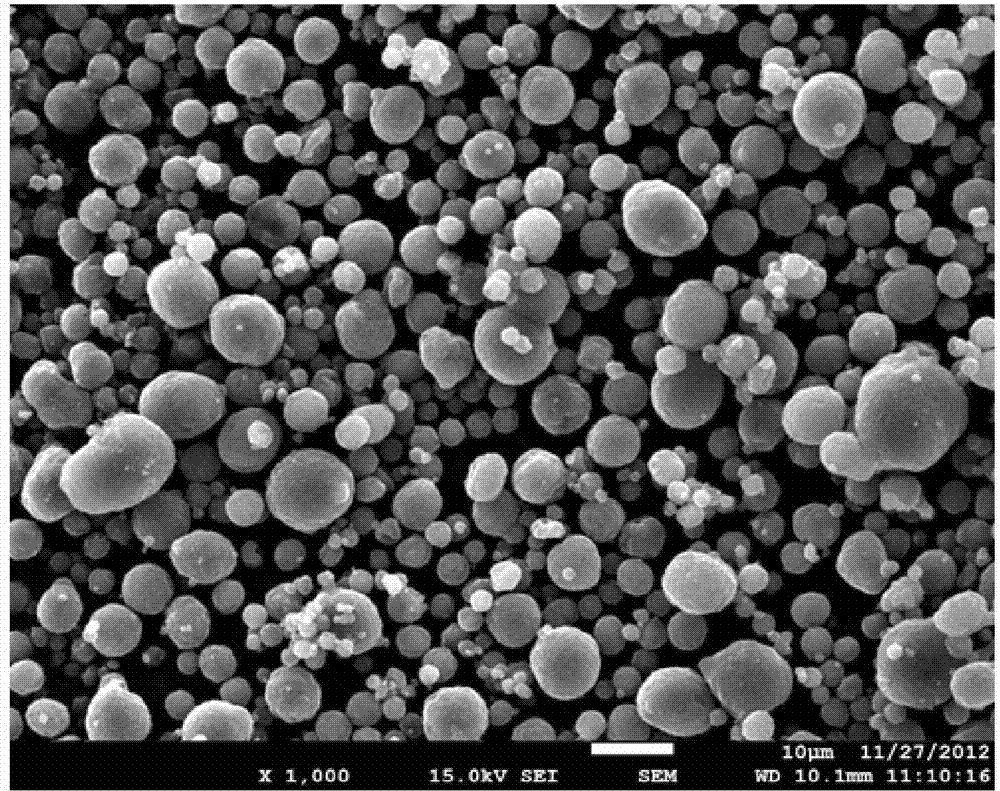

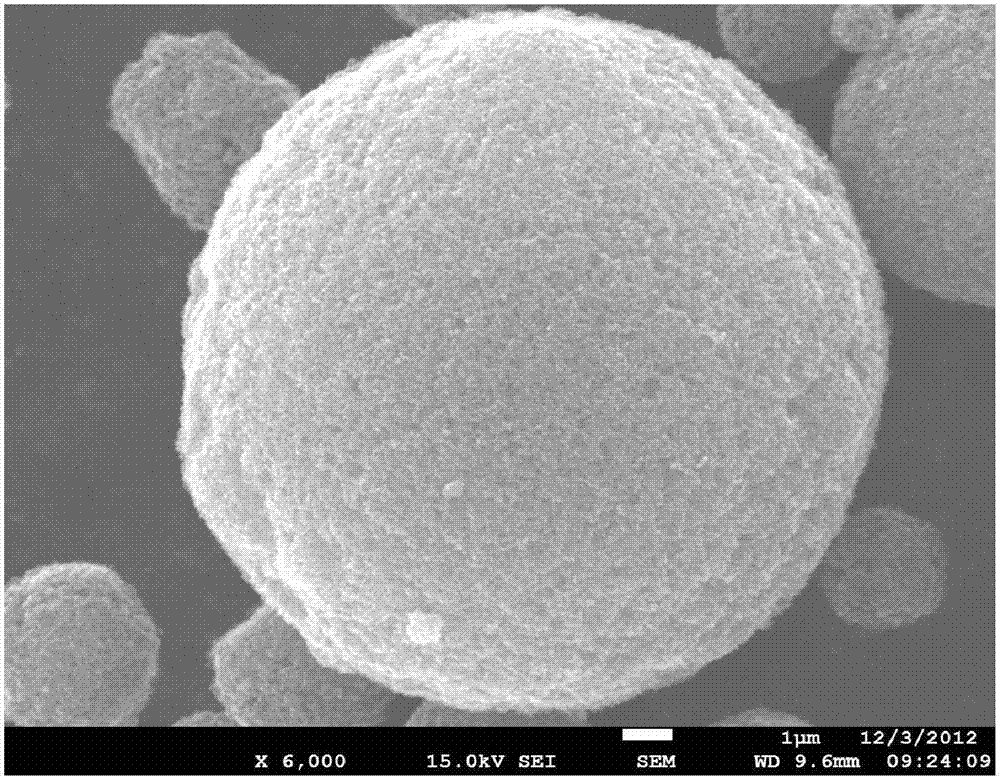

[0063] The carbon microsphere material prepared in Example 1 was used to observe the surface morphology of the carbon microsphere with a JSM6700 type field emission scanning electron microscope (Japan Electronics Co., Ltd.). figure 1 For the SEM figure of the carbon mi...

Embodiment 2

[0068] A preparation method of carbon microsphere negative electrode material for lithium ion battery:

[0069] (1) Mix 5 grams of carbon black, 2.5 grams of glucose and 100 grams of water, and stir at 30°C for 2 hours to obtain a slurry;

[0070] (2) The slurry obtained in step (1) is dried and formed through the spray drying process, and the spray drying inlet temperature is 250°C, and the outlet temperature is 70-150°C; after drying, the initial carbon microspheres can be obtained ;

[0071] (3) The initial carbon microspheres obtained in step (2) were subjected to a high-temperature treatment at 1300° C. for 5 h under a nitrogen atmosphere to obtain a carbon microsphere anode material.

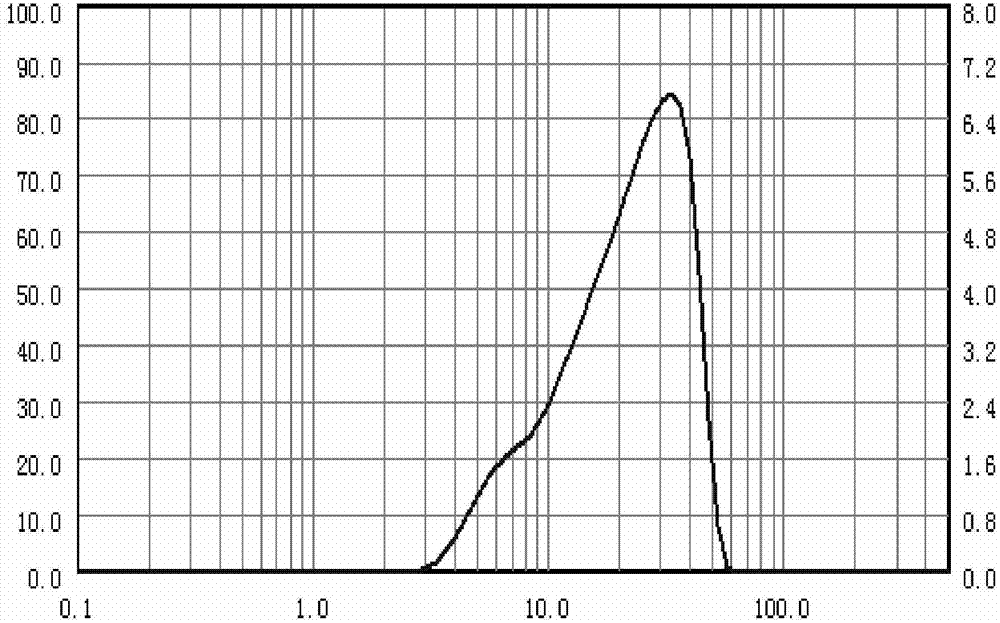

[0072] Figure 4 For the SEM figure of the carbon microsphere negative electrode material that embodiment 2 obtains, by Figure 4 It can be seen that the sphericity of the carbon microsphere particles is good. The particle size of the carbon microspheres was analyzed by a particle size...

Embodiment 3

[0074] A preparation method of carbon microsphere negative electrode material for lithium ion battery:

[0075] (1) Mix 5 grams of carbon black, 3 grams of cellulose and 80 grams of water, and stir at 40°C for 3 hours to obtain a slurry;

[0076] (2) The slurry obtained in step (1) is dried and formed through the process of spray drying into balls. The spray drying inlet temperature is 300°C, and the outlet temperature is 70-150°C; after drying, initial carbon microspheres can be obtained ;

[0077] (3) The initial carbon microspheres obtained in step (2) were subjected to a high-temperature treatment at 900° C. for 5 h under a nitrogen atmosphere to obtain a carbon microsphere anode material.

[0078] Figure 5 It is the SEM image of the carbon microsphere negative electrode material obtained in Example 3. The carbon microsphere particles have good sphericity, and the particle size analysis shows that the carbon microsphere particle size is between 1 and 40 microns; the ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com