Separation device and method for tar powder in TDI recovery liquid

A separation device and recovery liquid technology, applied in separation methods, chemical instruments and methods, purification/separation of isocyanic acid derivatives, etc., can solve treatment equipment pollution, reduce the content of chlorine-containing group compounds, and reduce the corrosion rate of purified TDI problems such as high recovery rate, good stability, and avoiding the risk of evaporation to dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

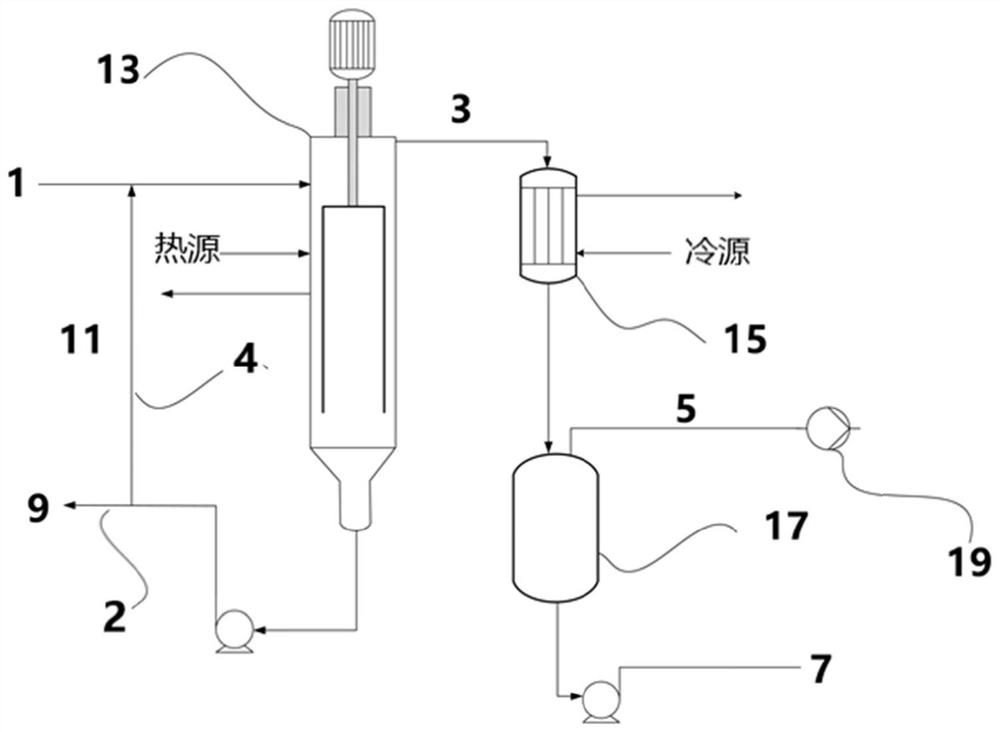

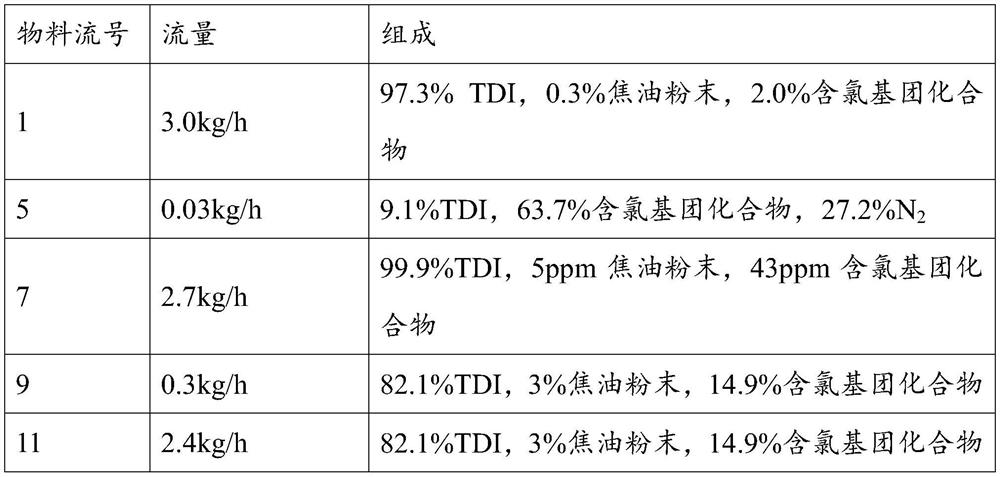

[0045] Obtain the TDI recovery liquid that contains tar powder as drying device by vacuum rake dryer, and according to such as figure 1 The separation process of the shown separation device separates and purifies the TDI recovery liquid, and the relevant equipment and logistics information are as follows in Tables 1 and 2:

[0046] Logistics information in Table 1 Example 1

[0047]

[0048] Equipment information in Table 2 Example 1

[0049]

[0050]

Embodiment 2

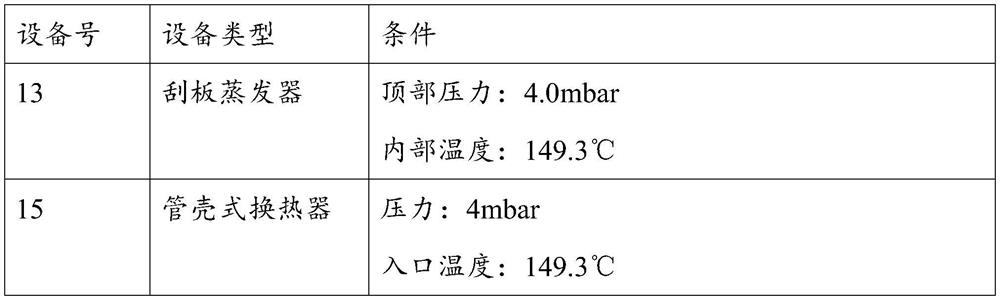

[0052] Obtain the TDI recovery liquid that contains tar powder as drying device by vacuum rake dryer, and according to such as figure 1 The separation process of the shown separation device separates and purifies the TDI recovery liquid, and the relevant equipment and logistics information are as follows in Tables 3 and 4:

[0053] Logistics information in the embodiment 2 of table 3

[0054]

[0055] Equipment information in Table 4 Example 2

[0056]

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com