Isodewaxing catalyst, preparation method thereof and method for producing lubricant base oil

A technology of isomerization dewaxing and catalyst, which is applied in the field of lubricating oil base oil, can solve the problems of high cloud point and achieve the effect of low pour point, excellent performance and improved conversion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

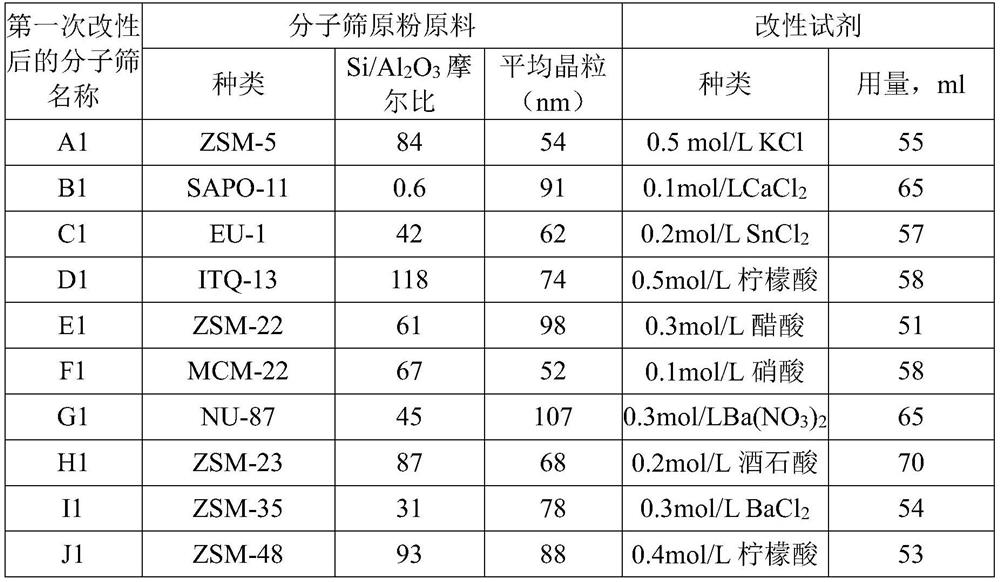

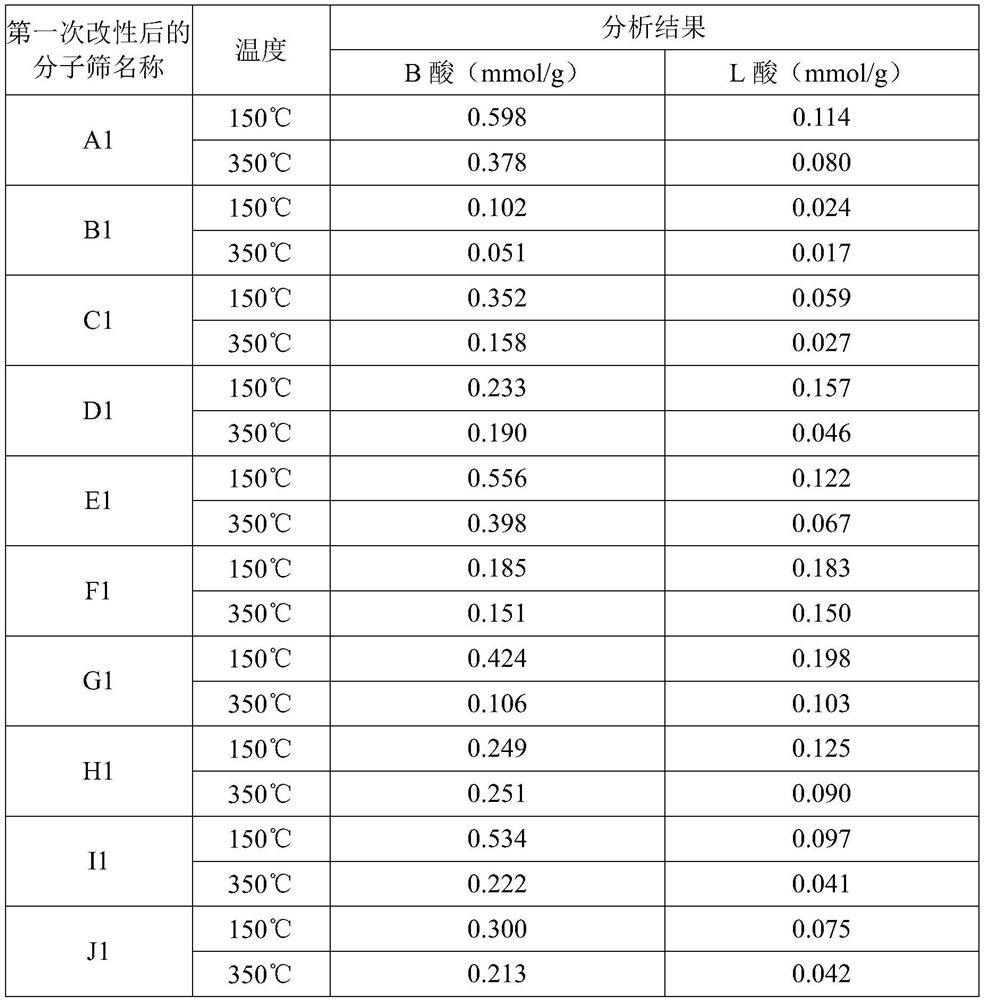

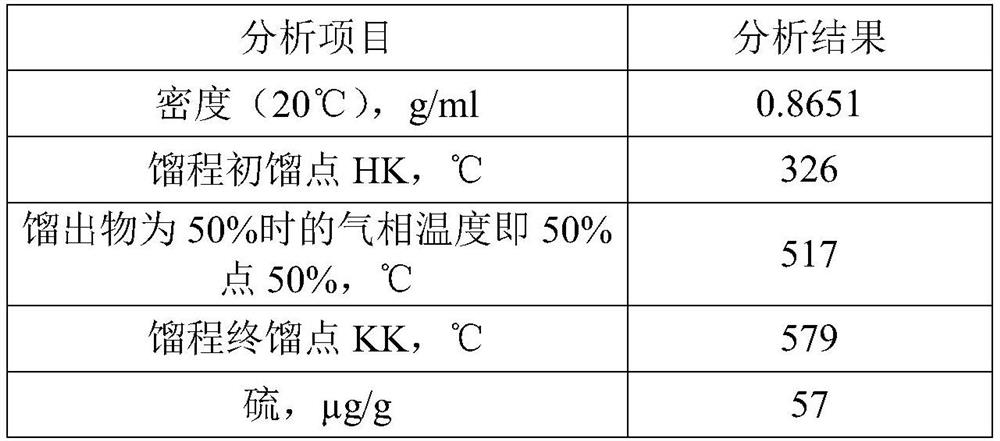

[0062] The commercially available industrial application molecular sieve raw powder ZSM-5, SAPO-11, EU-1, ITQ-13, ZSM-22, MCM-22, NU-87, ZSM-23, ZSM-35, ZSM-48 were used concentration The solution of the alkali metal salt of 0.1-0.5mol / L and / or the acidic solution with a concentration of 0.1-0.5mol / L is modified (the specific modification method is to impregnate the original molecular sieve with the solution of the alkali metal salt and / or the acidic solution powder), wherein the ratio of the mass of the original molecular sieve powder to the volume of the modified solution is 100g: 50-70mL, and the modified molecular sieve is then dried and calcined at 550°C for 4-10 hours to obtain the first modified molecular sieve; Wherein, the above molecular sieves are respectively taken 100g for illustration, the Si / Al of the above molecular sieves 2 o 3 The molar ratio is 0.5-120, the average grain size is 50-100nm, and the modified products and modifying reagents are shown in Table 1...

Embodiment 2

[0069] This embodiment provides a kind of isomerization dewaxing catalyst A1, and its preparation method is as follows:

[0070] 1) Mix 70g of the first modified molecular sieve A1 prepared in Example 1 with 40g of alumina powder, and extrude to obtain a wet strip; dry the wet strip at 200°C for 5 hours and use 0.1mol / L 200ml of KCl solution was impregnated to achieve the second modification, and then dried at 100°C and calcined at 550°C for 5 hours to prepare the second modified molecular sieve, that is, the catalyst carrier;

[0071] 2) The PtCl-containing 2 and PdCl 2 solution impregnated onto the catalyst carrier (i.e. the second modified molecular sieve), then dried at 120°C and calcined at 550°C for 4 hours to prepare Catalyst A1; wherein, the Pt and Pd contents in Catalyst A1 were 0.3wt% And 0.2wt% (based on catalyst mass).

Embodiment 3

[0073] This example provides a kind of isomerization dewaxing catalyst A2, the difference between its preparation method and Example 2 is: using 100g of the first modified molecular sieve A1 prepared in Example 1 and kneading with 20g of alumina powder, The two calcination temperatures were all 450° C., and the calcination time was 10 hours. The contents of Pt and Pd in the catalyst A2 were 1.0 wt % and 0.1 wt % (by catalyst mass), and the others were the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com