Pigment sludge treatment method

A treatment method and pigment technology, applied in biological sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve low anaerobic digestion efficiency, poor passivation efficiency, and difficult degradation of pigment sludge High organic content and other problems, to achieve the effect of reducing bioavailability, avoiding over-acidification, and reducing the risk of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

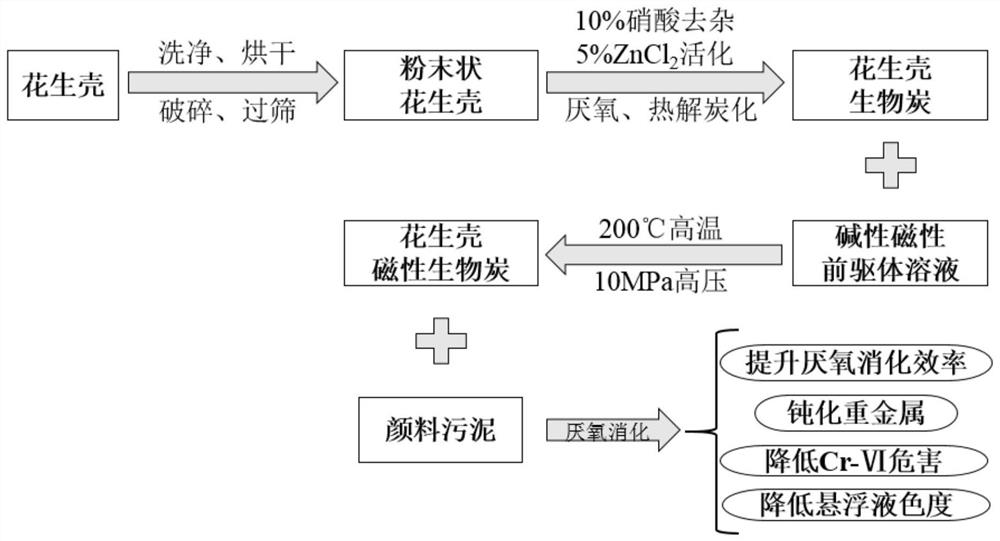

[0044] A treatment method for pigment sludge, comprising the steps of:

[0045] 1. Wash the peanut shells and dry them in an oven at 105° until the quality does not change. Crush the dried peanut shells and pass them through a 100-mesh sieve to obtain crushed peanut shells;

[0046] 2. Take 200g of powdered peanut shells, add 1L of 10% nitric acid solution, seal for 24 hours, oxidize to remove impurities in the peanut shells, rinse with deionized water until neutral, and dry in an oven at 105°C until the quality remains unchanged;

[0047] 3. Take the powdered peanut shell obtained in step 2, add 1L 5% ZnCl 2 The solution was activated, stirred magnetically for 24 hours, filtered, and dried in an oven at 105°C until the quality remained unchanged;

[0048] 4. Take the powdered peanut shells obtained in step 3, put them into an anaerobic muffle furnace at 600°C, and perform pyrolysis and carbonization for 4 hours to prepare peanut shell biochar, which is stored for later use; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com