Difunctional elastic polyurea adhesive as well as preparation method and application thereof

A dual-function, adhesive technology, applied in structural parts, electrochemical generators, electrical components, etc., can solve the problem of difficult to adapt to the volume expansion of alloy negative electrode materials, and achieve excellent self-healing performance, low cost, and preparation process. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of above-mentioned bifunctional elastic polyurea adhesive, comprises the following steps:

[0036] Step 1, placing polyethylene glycol with a weight-average molecular weight of 1000-10000 in a reactor, and distilling under reduced pressure in an oil bath at 110°C and magnetic stirring for 2 hours to remove the water therein to obtain reactant A;

[0037] Step 2, dissolving the diisocyanate in the solvent to obtain a diisocyanate solution; lower the temperature of the oil bath where the reactant A is located to 75°C, and drop the diisocyanate solution into the reactor to obtain a reaction system B; the diisocyanate is isocyanate Phorne diisocyanate IPDI.

[0038] Step 3, adding a catalyst, heating and reacting under the protection of nitrogen to obtain a prepolymer, the reaction temperature is 75°C, and the reaction time is 2h; the added catalyst is one or a mixture of organotin catalysts or amine catalysts, The dosage of the catalyst is 0.05-1% o...

Embodiment 1

[0044] The invention discloses a dual-functional elastic polyurea adhesive and its preparation method and application. The preparation of the adhesive specifically includes the following steps:

[0045] Step 1, weigh polyethylene glycol (PEG2000) with Mw=2000 and place it in a three-necked flask, and distill under reduced pressure for 2 hours in an oil bath at 110° C. under magnetic stirring to remove the water therein;

[0046] Step 2: Cool the oil bath to 75°C, weigh diisocyanate and dissolve it in N,N-dimethylformamide (DMF) solvent, and add it dropwise to a three-necked flask;

[0047] Step 3, adding a dibutyltin dilaurate (DBTDL) catalyst, the amount of the catalyst is 0.1% of the total mass of polyethylene glycol and diisocyanate, heating the mixed solution at a reaction temperature of 75° C. for 2 hours under nitrogen protection and magnetic stirring to obtain prepolymer;

[0048] Step 4: Cool the oil bath to 40°C, weigh the biuret chain extender with an electronic bal...

Embodiment 2

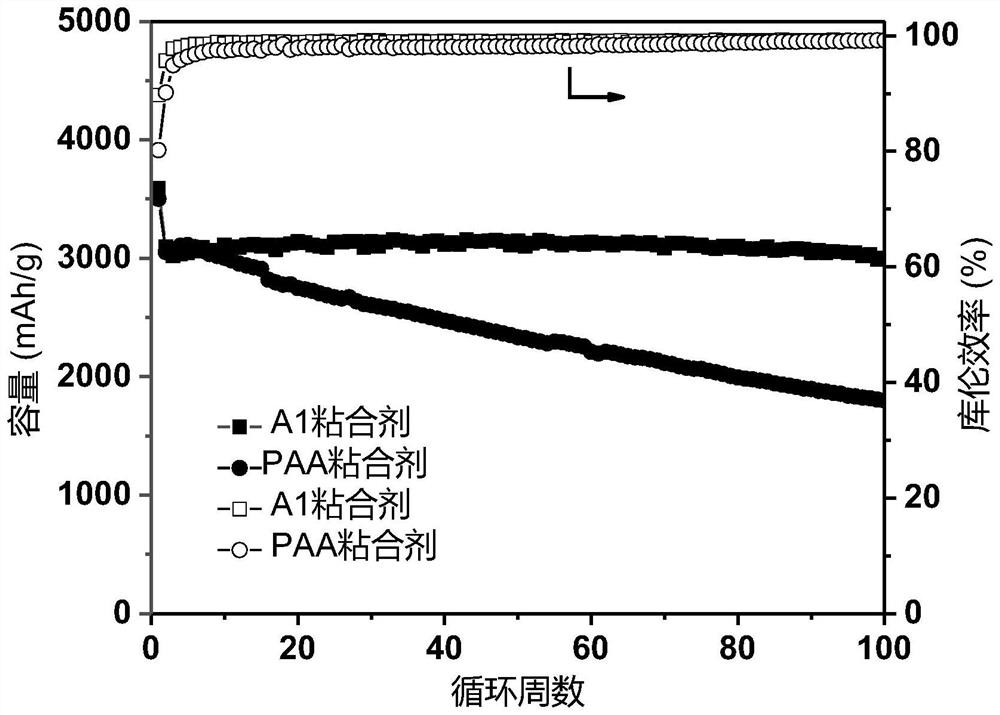

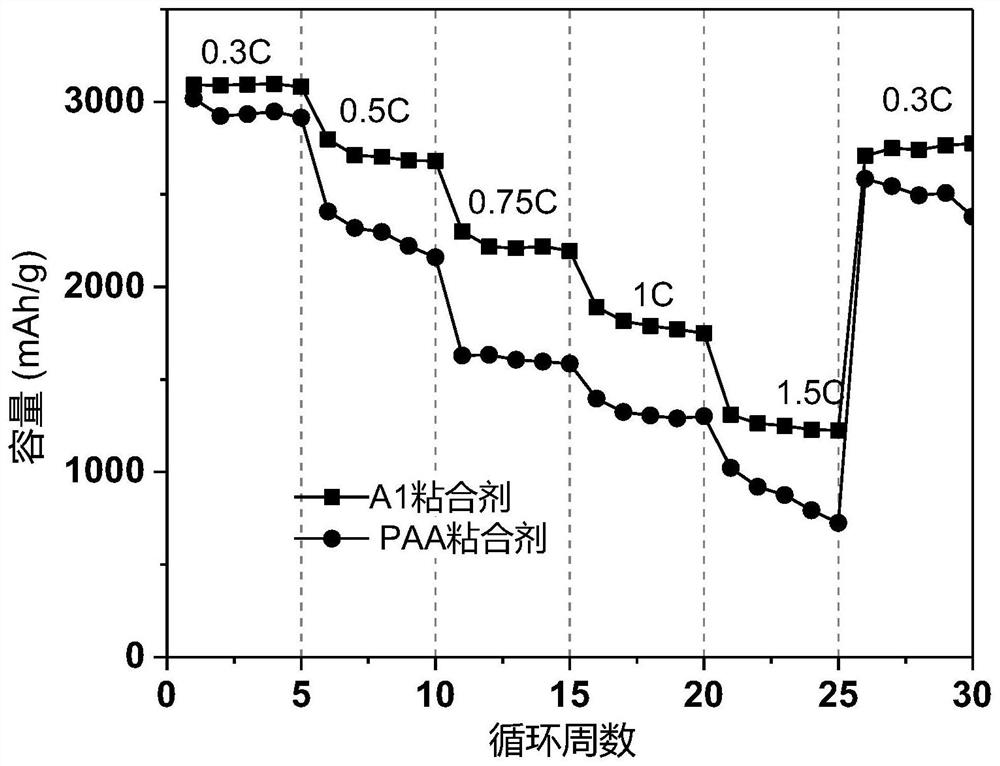

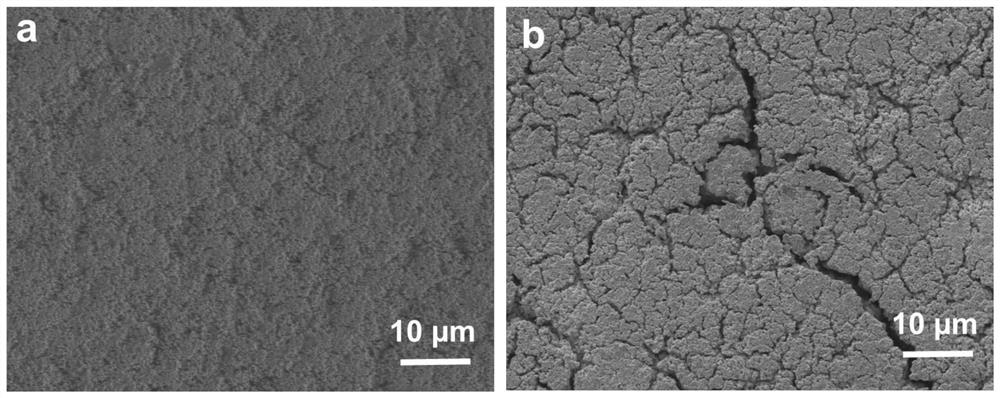

[0063] Synthesize the bifunctional elastic polyurea adhesive A1 with self-healing properties and ion-conducting properties, and all the steps are the same as in Example 1.

[0064] Use the synthesized polyurea binder A1 to prepare the silicon-carbon negative electrode for lithium-ion batteries. The preparation process is as follows: disperse silicon carbon particles and Super-P conductive carbon black into the synthesized polyurea binder A1 solution, and ball mill in a planetary ball mill 1h to make it fully mixed to obtain a homogeneously mixed negative electrode slurry. The slurry was coated on the copper foil current collector with an automatic film coating machine with a coating thickness of 50 μm, and the final electrode was obtained after vacuum drying at 120° C. for 2 h. The mass ratio of silicon carbon material, conductive carbon black, and binder A1 is 80:10:10. The above electrode was cut into pieces by a manual punching machine to obtain a silicon carbon negative e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com